Principles Of Mineral Crusher

2022-07-09T08:07:41+00:00

Crushing Principles of Mechanical Crushing 911

2016年1月11日 Crushing Principles of Mechanical Crushing Explain the interaction between rock material and crusher Crusher Application Cone Crusher Operating Principle Crusher Capacity Crusher Operation2016年1月11日 • The cone crusher design concept is an effective and smart way of realizing compressive crushing • Aggregate Production • Mechanical Liberation of Crushing Principles of Mechanical Crushing 911 2017年3月4日 A Balasubramanian University of Mysore Abstract and Figures In the field of extractive metallurgy, mineral dressing is the (PDF) SIZE REDUCTION BY CRUSHING METHODS

A review of modeling and control strategies for cone crushers

2021年8月15日 This work opens with a brief review of the mechanical principles of cone crushers Then, in the following sections, works available in the cone crusher literature, 2022年1月14日 Commonly used crushers include jaw crusher, impact crusher, hammer crusher, cone crusher, etc This article will introduce the working principles of these four Working Principle of 4 Commonly Used Crushers miningpediaThe primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw Cone Crusher an overview ScienceDirect Topics

(PDF) Efficient Modeling and Control of Crushing Processes in Minerals

2019年12月10日 crusher is a crusher that will exert the particles to a specific force, compared to machines that exert the particles to a fixed compression (form conditioned) 2016年1月1日 Abstract This chapter deals with the designs and operation of different types of roll crushers Two main types are indicated The first type where the rolls are Roll Crushers ScienceDirectGyratory and Cone Crusher In Mineral Processing Design and Operations (Second Edition), 2016 Abstract Detail descriptions of designs are given of large gyratory crushers that Primary Crusher an overview ScienceDirect Topics

Breakage process of mineral processing comminution

2020年9月1日 Comminution principle: Compression, impact, abrasion and attrition – – Mathematical simulations for breakage rate and breakage function of cone crusher [43] See Full PDFDownload PDF INTRODUCTION TO MINERAL PROCESSING FLOWSHEET DESIGN f Introduction • The flowsheet shows diagrammatically the sequence of operations in the plant • Most flowsheets use symbols to represent the unit operations • The flowsheet is the “roadmap” of a process, • It serves to identify and focus the scope of INTRODUCTION TO MINERAL PROCESSING FLOWSHEET DESIGN2023年2月28日 Working Principle of Secondary Crushers The working principle of secondary crushers varies depending on the type of crusher, but generally, they work by applying pressure to the material through The Complete Guide to Primary Crushing,

A review of modeling and control strategies for cone crushers

2021年8月15日 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017)The maximum distance between the mantle and concave, on the other 2022年11月21日 crusher frame by means of a toggle plate The kinematics of this type of toggle system result in a higher capacity than that achieved with a doubletoggle jaw crusher with the same feed opening The diversity of feed mate rials has led to a diversification of singletoggle jaw crushers to suit the particular rock hardnessIndustrial Solutions Jaw crushers ThyssenKruppContribute to yunan88/crusher development by creating an account on GitHubcrusher/ principles of mineral processing miningmd at

What Is A Jaw Crusher MEKA

1) Obtaining the size or surface area required for the use of the ore or material 2) Allowing ease of transportation and storage 3) Separating the different minerals contained within the ore and to release them from one another 4)2022年12月14日 Stone Crushers Jaw Crusher is a kind of Stone crusher and jaw crusher solution » principles of mineral dressing a m gaudin; hsi stone crusher 14 550 Principles of Mineral Dressing Hardcover – December, 1939 by AM Gaudin (Author) 50 out of 5 stars 2 customer reviews See all 3 formats and editions Hide other formats and editionsMineral dressing by gaudin pdf Canadian examples 2016年2月17日 The crusher head is at the moment in the closeside position Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1” Note that the length of line “1″ from concave to openside head position, is the same as that of Working Principle of Crushers 911 Metallurgist

Roll Crushers ScienceDirect

2016年1月1日 The roll size of a roll crusher was 305 cm × 901 cm Gypsum rock (SG = 27, bulk density = 17 t/m 3) is to be crushed Determine 1 the set in order to crush at the rate of 12 t/h and 10 rpm speed of the rolls, 2 the ratio between capacity and peripheral speed if the set was 25 cm, 3 the nip angle when the crusher feed size is 10 cm,Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediaterange sizereducing machines A schematic diagram of a cone crusher is shown in Fig 46 AThe drive is similar to that of a gyratory crusher The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the Cone Crusher an overview ScienceDirect Topics2021年11月22日 considered a waste or gangue material Within an ore body, valuable minerals are surrounded by gangue and it is the primary function of mineral processing, to liberate and concentrate those valuable minerals 12 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a Introduction to Mineral Processing Sepro Labs

Crushers and Their Types – IspatGuru

2015年4月3日 The purpose of crusher is to reduce the size of the materials for making them usable in construction or industrial use, or for extraction of valuable minerals trapped within a ore matrix Crushing is the process of 2021年11月1日 Fig 3 illustrates the operating principle and the main components of a cone crusher A cone crusher basically comprises two bellshaped manganese crushing liners placed inside each other The concave is attached to the crusher frame and the mantle to the eccentric main shaft which is swaying around the geometric center point at the Size reduction control in cone crushers ScienceDirect2020年12月1日 Here the particles are represented as superquadrics, which in their principle reference frame, are: (1) (x a) m + (y b) m + (z c) m = 1 The particle aspect ratios are given by the ratios of the semimajor axes b/a and c/a The exponent m determines the blockiness of the particle A spherical particle has exponent m = 2 and unit aspect ratios Advanced comminution modelling: Part 1 – Crushers

Gyratory and Cone Crusher ScienceDirect

2016年1月1日 The secondary crushers are also designed on the principle of gyratory crushing, but the construction details vary the maximum product size possible is 10–15 cm which is normally too large for down stream processing for mineral liberation Hence, secondary and possibly tertiary crusher stages form part of the crushing circuit design 2020年9月16日 According to the different crushing principle and particle size of size, the types of crusher is divided into many kinds and a variety of new types of crusher have been widely developed, mainly Five Types of Crusher in the Mineral Processing LinkedInContribute to sili2023/ development by creating an account on GitHub/ principles mineral crushermd at main sili2023/

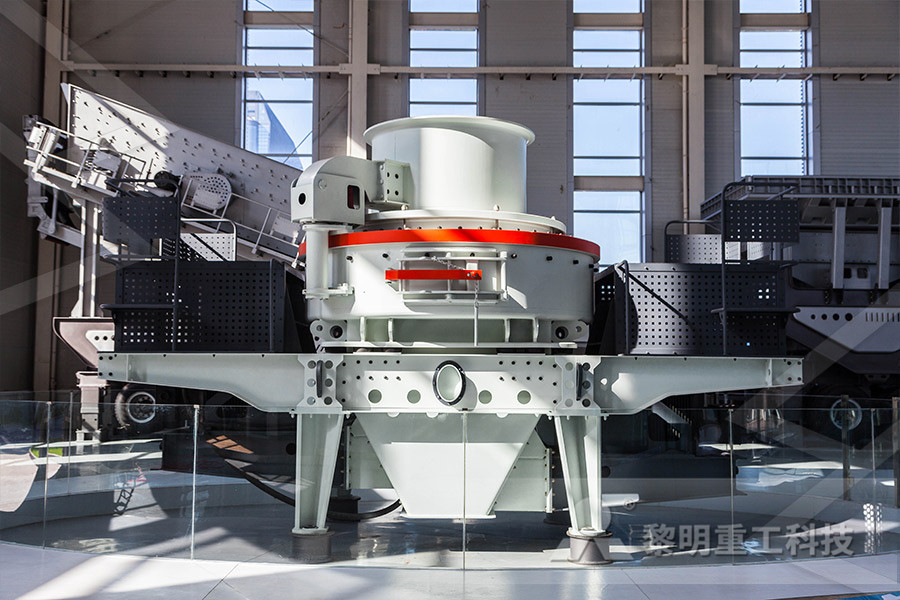

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc Crushing is the first of many stages that lead to separation of the mineral(s) from the waste (gangue) material Waste material can be discarded or recycled 2017年6月2日 Jaw crusher Mineral sizers are one of the newer technologies to the crushing industry They feature two rotors, each fixed with large teeth that rotate in opposite directions at low speeds The material to be crushed is fed onto the rotors and is gripped and then crushed between the teeth When sufficiently reduced, the crushed material falls How it Works: Crushers, Grinding Mills and Pulverizers