What Are The Equipment Required For Iron Ore Beneficiation Plant

2023-04-09T20:04:28+00:00

Iron ore beneficiation: an overview ScienceDirect

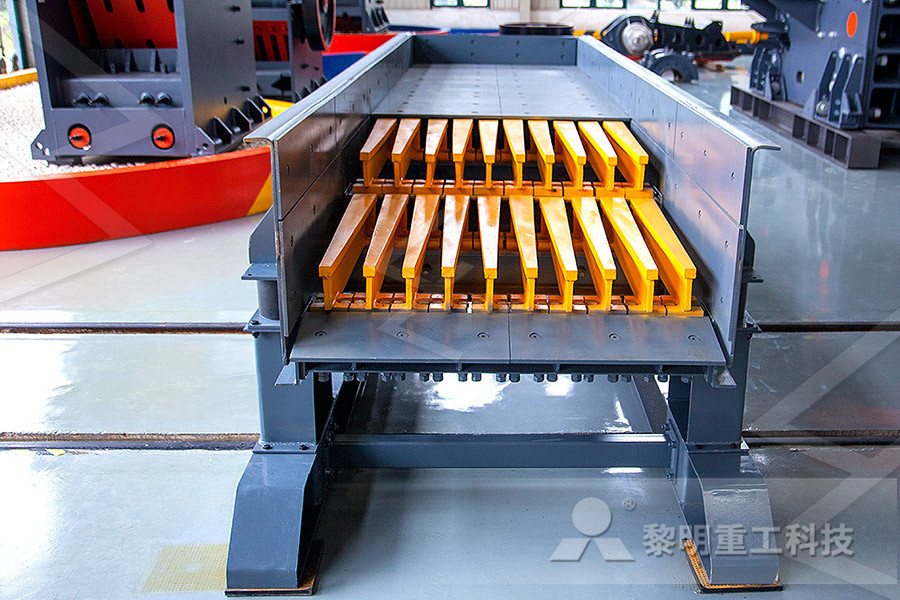

2023年1月1日 This chapter briefly discusses the current scenario of the iron ore resources in India, iron ore mining methodology, beneficiation technique, and the current operating practices for achieving sustainable growth in the iron and steel industry2015年1月27日 Currently, blast furnaces are mainly used for ironmaking They would suffer from greatly reduced productivity and a high energy consumption rate, if lowgrade ore Beneficiation Plants and Pelletizing Plants for Utilizing 2023年9月30日 Industrially valuable iron minerals are magnetite, hematite, limonite and siderite Iron ore beneficiation mainly includes crushing, grinding, gravity separation, flotation and magnetic separation Magnetic Iron Ore Beneficiation Plant Mineral Processing

World leader in fine iron ore beneficiation Mineral

2022年4月1日 cost effective fine iron ore beneficiation for the highly variable low‑grade ore Innovative plant design Extending beyond traditional spiral plants our designs for fine iron 2020年2月8日 The beneficiation techniques such as scrubbing, classification, gravity separation, magnetic separation and flotation are generally utilized to enhance the quality Existing and New Processes for Beneficiation of Indian Iron 2017年10月24日 for beneficiating iron ore to extract magnetite, hematite and goethite Starting with metallurgical testing, we test samples as small as 100 grams for Your iron ore beneficiation solutions downergroup

Iron ore beneficiation Commodities Mineral Technologies

Extending beyond traditional spiral plants our designs for fine iron ore beneficiation incorporate gravity and magnetic beneficiation equipment with capacities ranging from 5 The increasing demand of iron ore at home and abroad further stimulates the development of the benefication of iron ore As one of the leading enterprises in domestic mineral Beneficiation of Iron, Iron Extraction Process, Iron Ore To evaluate an iron ore resource, develop processing routines for iron ore beneficiation, and understand the behavior of the ore during such processing, extensive mineralogical Ore Beneficiation an overview ScienceDirect Topics

Comminution and classification technologies of iron ore

2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) products2022年4月6日 The promoters of M/s IMPL has envisaged to establish an Integrated Steel Plant with Iron Ore Beneficiation Plant of 12 MTPA, Iron Ore Pelletisation Plant of 072 MTPA, Sponge Iron Plant of 051 MTPA, Induction Furnace of 029 MTPA, Rolling Mill of 029 MTPA, Oxygen Plant of 100 TPD Ferro Alloys Plant of 2 x 9 MVA (0066 MTPA) PREFEASIBILITY REPORT2023年9月30日 Iron ore beneficiation is mainly a process of separating valuable minerals and iron minerals from ores to extract highquality iron ore The iron ore process mainly includes crushing, grinding, washing, Iron Ore Beneficiation Plant Mineral Processing

Iron Ore Pelletization Technology and its Environmental

2015年1月1日 Indian economy is growing steel demand and supply will grow in the same way As good quality iron ore deposits are depleting very fast beneficiation technologies have to be adopted to meet iron ore demand Agglomeration technologies such as Pelletization / Sintering have to be added to Steel Plant so that concentrates can be used 2020年5月6日 FUNDAMENTALS OF IRON ORE SINTERING R P Bhagat INTRODUCTION The process of sinter making originated from a need to make use of fines generated in mines and in ore benefiCiation plants With the development of sintering technology, a sintering plant has become a tremendous success for providing a CHAPTER11 FUNDAMENTALS OF IRON ORE SINTERING2014年7月28日 BENEFICIATION OF IRON ORE A THESIS SUBMITTED IN PARTIAL FULLFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF Bachelor of Technology In Mining Engineering By SANJAY KUMAR AGARWAL 110MN0569 SUDHANSHU KUMAR 24 Slimes of Iron ore 11 3 BENEFICIATION PLANT STUDY BENEFICIATION OF IRON ORE National Institute of

Iron Ore ScienceDirect

Iron ore is regarded as the second most important commodity behind oil As an essential input for the production of crude steel, iron ore feeds the world’s largest trilliondollarayear metal market and is the backbone of global infrastructure To meet the growing demand for steel products, world iron ore production has increased 2018年7月11日 Bentonite, an inorganic binder, has been the main binder used in the iron ore pelletizing process since the beginning of pellet production in the 1950s Bentonite promotes the forma tion of (PDF) Iron Ore Pelletizing Process: An Overview ResearchGateThe beneficiated ore is utilised as feed for DRI, Sinter and Pellet plant Provision is also made to feed directly 020 mm raw material as plant feed Effluent from the iron ore beneficiation plant is treated in thickener and clarified water from the thickener overflow is recycled Thickener underflow slurry is further sent to a filter press Iron Ore – Beneficiation Pelletization Division EMIL

Magnetite Beneficiation, Equipment Mineral Processing

2023年9月29日 Magnetite beneficiation Process 1 Single Magnetite: Most of the iron minerals in a single magnetite ore are magnetite The ore composition is simple, and the weak magnetic separation process is often used: When the grinding particle size is more than 02mm, most iron ore magnetic separation plants often adopt a onestage grinding – Rio Tinto Iron Ore's lowgrade ore beneficiation plant in the Pilbara was commissioned in 1979 Initial engineering, design, and construction were undertaken by KBR (Kellogg Brown and Root) and Minenco (RTIO information provided to author, 2013) This is followed by review of comminution circuits and equipment for magnetite ores including Ore Beneficiation an overview ScienceDirect Topics2023年2月15日 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation Mediumgrained hematite refers to iron ore with an embedded particle size between 002 and 2mm How to Extract Iron from Hematite: Methods and

Hazard Identification, Risk Assessment, and Control

General India has the fourth largest iron ore reserves in the world after Russia, Brazil, and Australia[] As per the survey conducted by the Indian Bureau of Mines (IBM) in April 2000, India had 9919 million tonnes of recoverable reserves of haematite and 3546 million tonnes of magnetite[]As good quality iron ore deposits are depleting very fast, beneficiation 2020年2月2日 ROM iron ore with Fe less than 58 – 60% discarded as waste After beneficiation iron ore availability can improve by about 50% Steel community and the country demand technological solutions for utilising low grade ores The technology task that would be imperative: 1 Utilisation of low grade iron ores after beneficiation 2SINTERING AND PELLETISATION OF INDIAN IRON ORES2015年12月31日 A brief introduction to recent developments in iron ore pelletizing is provided in this chapter, including the world output of fired pellets, pellet production processes, preparation of pellet (PDF) Iron ore pelletization ResearchGate

Developments in nonmagnetic physical separation technologies for

2015年1月1日 Iron ore beneficiation is therefore opposite to coal beneficiation where DMS is even more extensively used but where the floats represent the desired outcome Another notable difference is that while coal DMS can use a cheaper medium made up of ground magnetite particles, the higher separation densities required in iron ore beneficiation (in 2020年7月6日 The company’s BATAC jigs are becoming increasingly popular in the iron ore beneficiation sector due to their rapid detection of changes in the raw material, quick reaction to such changes and easy operation Kottmann says that BATAC jig technology has excellent separation accuracy, is relatively small in footprint and has a comparatively low Increasing throughput and decreasing maintenance in the iron ore 2015年1月27日 Recently, the grade of iron ore deposits has deteriorated and further development of low grade deposits is desired Presently, the most effective and often followed route taken to utilize such deposits is the provision of beneficiation plants for upgrading iron ore and pelletizing plants for agglomerating Kobe Steel has much Beneficiation Plants and Pelletizing Plants for Utilizing

Iron ore pelletization ScienceDirect

2015年1月1日 The ratio in the output from the three main pelletizing technologies changes depending on practical circumstances, such as iron ore reserves, iron ore types, market demand, and required investment The ratio for gratekiln pellets has increased to 5533% in 2011 from 721% in 2000, while the ratio for shaft furnace pellets has dropped to 4205% 2018年7月17日 The iron ore pelletizing process consists of three main steps: 1 Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives anthracite, dolomite and binders are prepared in terms of particle size and chemical specifications, dosed, and mixed together to feed the pelletizing process; 2Iron Ore Pelletizing Process: An Overview IntechOpen