Ball Mill Processing Equipment For Magnesite In Bolivia

2022-02-26T01:02:16+00:00

Research on new beneficiation process of lowgrade magnesite

2020年4月14日 We conducted experiments involving the reverse flotation and positive flotation of lowgrade magnesite to determine the optimum process parameters, and then 2020年4月14日 We conducted experiments involving the reverse flotation and positive flota tion of lowgrade magnesite to determine the optimum process parameters, and Research on new beneficiation process of lowgrade 2020年5月1日 Presently, research on the largescale mill in China and internationally has been focused on process optimization via replacing the conventional grinding process Enhancing the capacity of largescale ball mill through process

Process Flow of Magnesite Calcination by Rotary kilnZK Ball Mill

2021年3月25日 The preheater independently developed and produced by Zhengzhou Mining Machinery has been successfully applied to the calcination of magnesite, saving The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective Ball milling: a green technology for the preparation and 2020年4月1日 We conducted experiments involving the reverse flotation and positive flotation of lowgrade magnesite to determine the optimum process parameters, and then Research on new beneficiation process of lowgrade magnesite

New horizon in mechanochemistry—hightemperature, high

2022年9月30日 open access Highlights • New mechanosynthesis method is presented • Temperature can be precisely controlled during planetary ball milling under H 2 pressure 2021年2月19日 The ball mill process parameters discussed in this study are ball to powder weight ratio, ball mill working capacity and ball mill speed As Taguchi array, also known Comparative Study on Improving the Ball Mill Process Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the Ball milling: a green technology for the preparation and

Machines Free FullText Planetary Mill with

2019年5月21日 Processing in planetary ball mills is well suited to a large number of applications because they are easy to operate and versatile, grinding faster than other mills Research related to planetary mills are The Bolivar deposit is a CuZn skarn and is one of many precious and base metal deposits of the Sierra Madre belt, which trends northnorthwest across the states of Chihuahua, Durango and Sonora in northwestern Mexico (Meinert, 2007) The deposit is located within the Guerrero composite terrane, which makes up the bulk of western Mexico and is Major Mines Projects Bolivar Mine2019年7月15日 In this study, several tests were examined to analyze the sortability of magnesium oxide (MgO) by the use of triboelectrostatic belt separation The objective of the study is to find a dry sorting technique to separate MgO from accompanying components such as CaO and SiO2 The aim of this first series of experiments was to develop Processing of Caustic Calcined Magnesite (Magnesium Oxide

Research on new beneficiation process of lowgrade

2021年1月5日 the vertical roller mill and ball mill The results show that the optimum process parameters for the vertical roller mill are as follows: a grinding fineness of 816wt% of particles less than 0074 mm, a dodecyl amine (DDA) dosage in magnesite reverse flotation of 100 gt−1, and dosages of2013年9月10日 Three in One Mobile Crusher limestone mobile crushing plant used in Qatar South Africa 30 tph limestone grinding plant Limestone grinding line in Kazan Russia South Africa 200 tph granite crushing line Philippines 150TPH Riverstone Crushing Plant Indonesia 180 tph Iron Ore crushing plant How Much VSI Sand CrusherMagnesite crusher Mining Quarry PlantYou've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitymill/ magnesite washing equipment pricemd at master mill

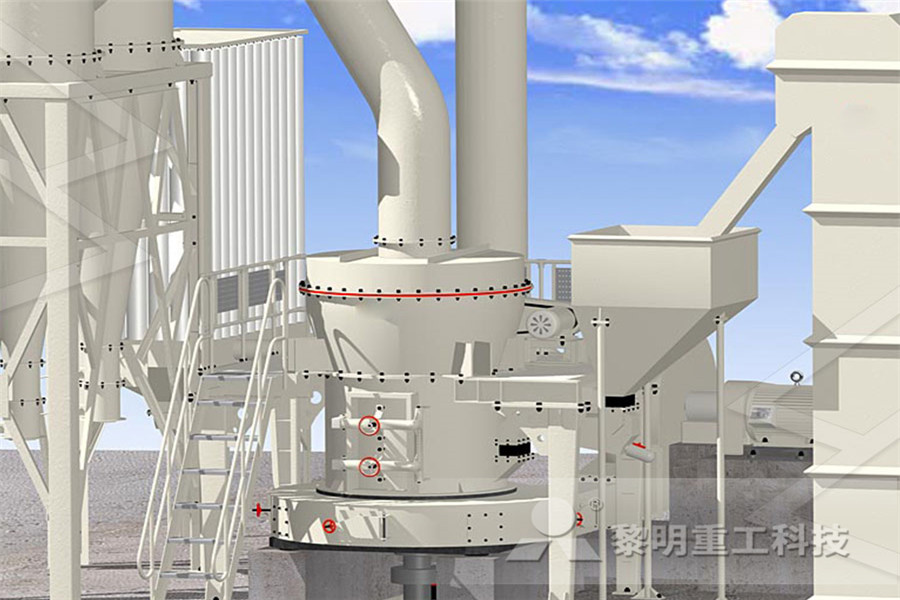

Ball Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement Kiln,

2023年9月1日 Ball Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement Kiln, Lime Kiln SupplierHenan ZK Corp already has been growing up to a comprehensive company with strong ability of the whole system researching and designing on process technology and equipment manufacturing in the fields of building materials, mining, metallurgy, Contribute to crush2022/mill development by creating an account on GitHubmill/ processing equipment for talc and magnesite 2023年7月5日 The magnesite samples used in the test were taken from a mineral processing plant in Liaoning Province, China, and the raw ore was coarsely crushed, medium crushed and finely crushed to obtain − 2 mm samples, and the raw ore particle size distribution is shown in Fig 1The Xray diffraction (XRD) was used to analyze the phase The role of sodium tripolyphosphate in wet grinding process of magnesite

Research on new beneficiation process of lowgrade magnesite

2020年4月14日 We investigated whether the vertical roller mill can be efficiently used in the beneficiation of lowgrade magnesite and whether it can improve upon the separation indices achieved by the ball mill We conducted experiments involving the reverse flotation and positive flotation of lowgrade magnesite to determine the optimum process 2021年7月16日 Rotary kiln is used as equipment for calcining magnesite to produce magnesia, with large production capacity, high degree of mechanization, high labor productivity and stable product quality In particular, the new clean production process of the external heating rotary kiln has completely changed the disadvantages of the traditional Magnesite Calcination Rotary kiln to Produce Light Burning 2020年4月14日 the vertical roller mill and ball mill The results show that the optimum process parameters for the vertical roller mill are as follows: a grinding fineness of 816wt% of particles less than 0074 mm, a dodecyl amine (DDA) dosage in magnesite reverse flotation of 100 gt−1, and dosages ofResearch on new beneficiation process of lowgrade

Research on new beneficiation process of lowgrade

2020年4月14日 the vertical roller mill and ball mill The results show that the optimum process parameters for the vertical roller mill are as follows: a grinding fineness of 816wt% of particles less than 0074 mm, a dodecyl amine (DDA) dosage in magnesite reverse flotation of 100 gt−1, and dosages ofQuantum Nanostructures (QDs): An Overview D Sumanth Kumar, HM Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3611 Ball Milling A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball Ball Mill an overview ScienceDirect Topics2021年3月25日 Calcination Process Requirements of Magnesite: 1 The temperature of the hot air in the calciner must be between 5001200°C 2 The particle size of the calcined material needs to be less than 60 mesh 3 Diversification of combustion fuels: solid (coal), gas (gas, natural gas), liquid (diesel, heavy oil) 4Process Flow of Magnesite Calcination by Rotary kilnZK Ball Mill

Ball Mills 911 Metallurgist

2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volumeThe invention belongs to the technical field of mineral dressing of magnesite, and particularly provides a novel process for purifying the magnesite The novel process adopts a ball mill and a classifier to perform reverse flotation and direct flotation, combines the reverse flotation and the direct flotation together, and comprises the following technological Novel process for purifying magnesite Google Patents2020年4月1日 Compared with the ball mill, the use of the vertical roller mill in the beneficiation of lowgrade magnesite resulted in a 128% increase in the concentrate grade of MgO and a 588% increase in Research on new beneficiation process of lowgrade magnesite

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation It consists of one or more rotating cylinders partially filled with grinding balls (made 2002年4月3日 Taking high grade magnesite or calcined magnesia as raw materials, 12 hours is required for the fusion process at temperatures in excess of 2750°C The process promotes the growth of very large crystals of periclase (>1000 microns compared with 50100 microns for dead burned magnesia) with a density approaching the theoretical Magnesia Forms, Applications and Production Processes