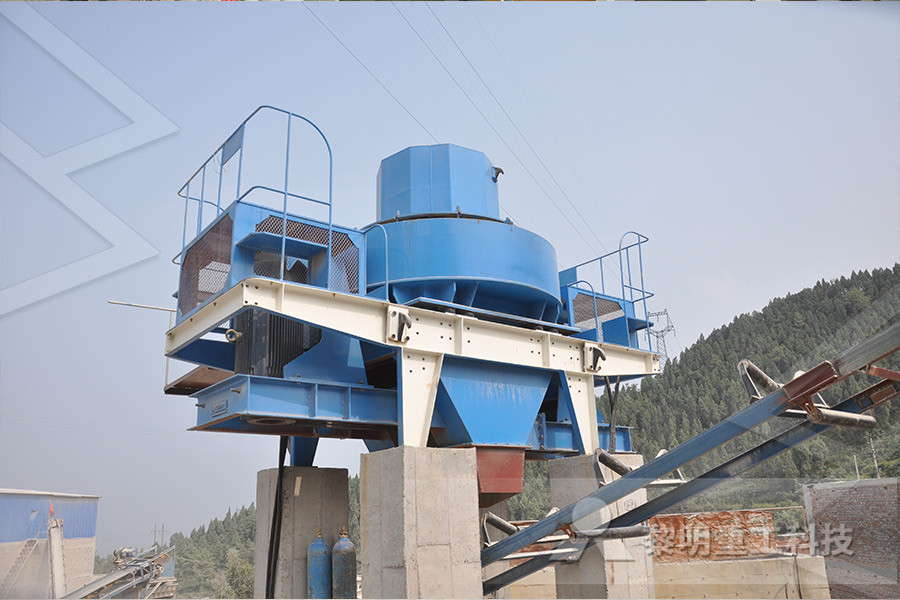

Reducing The Size Of Coarse Line Using Crushing Plant

2020-10-15T12:10:41+00:00

china/ reducing the size of coarse line using crushing plant

Contribute to crushers/china development by creating an account on GitHub2017年3月4日 SIZE REDUCTION BY CRUSHING METHODS Authors: A Balasubramanian University of Mysore Abstract and Figures In the field (PDF) SIZE REDUCTION BY CRUSHING METHODS2021年11月1日 Framework for size reduction control of crushing circuits • Feedback control methods to ensure consistent size reduction • Online measurement techniques to Size reduction control in cone crushers ScienceDirect

SIZE REDUCTION BY CRUSHING METHODS By

2023年9月29日 There are two kinds of equipments used for crushing works one is by using crushers and other one is by using impactors This diagram illustrates the stages of 2015年10月15日 Steadystate modelling and simulation tools are widely used in designing of a new process for industrial coarse comminution (PDF) Crushing Plant Dynamics ResearchGate2022年4月26日 a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes T he objective of the crushing (PDF) Optimization Capabilities for Crushing Plants

Aggregate Production Optimization in a StoneCrushing Plant Using

2020年2月8日 The process of size reduction is usually conducted using crushers, which are typically classified by the degree to which they portion the materials Rough materials A typical crushing plant consists of size reduction machines (eg, crushers) with intermediate separation machines (eg, screens), transportation equipment (eg, Optimization Framework for Crushing Plants ChalmersA crushing plant typically consists of a series of equipment to reduce the material size from coarser size to finer size, typically, in range of 01000 mm to 030 mm depending on the SIMULATIONDRIVEN DEVELOPMENT FOR COARSE

12 Springer

2017年8月23日 123 SIZE REDUCTION MACHINES 586 587 598 605 623 631 631 124 THE ANALYSIS OF SIZE REDUCTION PROCESSES 125 NEW MILLS 126 FUTURE The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 AMIT 135: Lesson 5 Crushing – Mining Mill In the industry, screening or sieving is widely used to evaluate particle size distribution in granular materials and powders In case of coarse crushing the size reduction ratios is below 8:1 and in fine grinding it is more than 100:1 Solids are broken mainly by four different ways, which are used in sizereduction machinesSize Reduction1: Grinding – Unit Operations in Food

How it Works: Crushers, Grinding Mills and

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can 2021年11月6日 The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral aggregate products Qualitative characteristics of crushing products in terms of size reduction ratio and fine particles contents were analyzed from the point of view of operational parameters of the impact Minerals Free FullText Optimization of Aggregate 2020年6月1日 The crusher and feed parameters used are closed side setting ( CSS ), speed, feed rate and feed gradation This paper presents a parameter study investigating the effect of feed and jaw crusher parameters on the quality of aggregates produced from singlestage crushing The parameter study is evaluated using mechanical and Influence of jaw crusher parameters on the quality of

11192 Crushed Stone Processing and Pulverized

2015年9月10日 Quarried stone normally is delivered to the processing plant by truck and is dumped into a bin A feeder is used as illustrated in Figure 111921 The feeder or screens separate large boulders from finer rocks that do not require primary crushing, thus reducing the load to the primary crusher2013年9月9日 Technical analysis reaffirm that Kick's equation could only achieve coarse particles as the final particle size showed average percentage deviation of 3840%, while Bond's equation may be limited METHODS OF SIZE REDUCTION AND FACTORS AFFECTING SIZE REDUCTION 2020年2月13日 Coarse comminution testwork and modeling are powerful tools in the design and optimization of mineral processing plants and provide information on energy consumption Additional information on mineral liberation characteristics can be used for assessing the potential of preconcentration stages or screens in the plant design In Understanding Mineral Liberation during Crushing Using GradebySize

Size reduction control in cone crushers ScienceDirect

2021年11月1日 Fresh feed rate and crusher feeding condition (chokefed/tricklefed) had significant impacts on size reduction of manual control Only automatic control compensated for the effect of feed rate and crusher feeding condition • CSS showed a decreasing trend to compensate for wear (both automatic and manual control) •71 A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was Crushing Plant an overview ScienceDirect Topics2021年2月26日 Recycled concrete aggregates (RCA) are used in existing green building composites to promote the environmental preservation of natural coarse aggregates (NCA) Besides, the use of RCA leads to Crystals Free FullText Use of Recycled Concrete

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The objective of this report is to provide the details of size reduction methods involved in mineral processing using crushing equipments Crushing is the first step of mineral processing where 2019年1月1日 The initial size distribution shows a single mode corresponding to a relatively coarse size, but as the degree of crushing is gradually increased, this mode progressively decreases in magnitude, and a second mode emerges at a particular size This process continues until the first mode has completely disappearedParticle Size Reduction and Enlargement ScienceDirect2021年6月24日 700mm coarse SD 285 t/m3 Abr 1227 g/t Cr 20 % 450 B13503V Load 75 % 450 Opening 100 mm 305 145 Lokotrack primary mobile crushing plant to further processing stages They are able to follow parameters online Original wear and spare parts – using original wear parts is the key to a successfulCrushing and Screening Handbook AusIMM

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021年12月3日 The present study investigates the effects of rock crushing circuits on aggregate quality For this purpose, a crushingscreening plant located in Vize (Kırklareli, Turkey) was considered122121 Liberation Size The first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron minerals A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure 122 (based on Ref [ 4 ])Crushing Circuit an overview ScienceDirect Topics2015年4月3日 Types of crushers Crushers are classified into three types based upon the stage of crushing they accomplish These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in sizeCrushers and Their Types – IspatGuru

Cone Crusher an overview ScienceDirect Topics

Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediaterange sizereducing machines A schematic diagram of a cone crusher is shown in Fig 46 AThe drive is similar to that of a gyratory crusher The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the 2020年9月16日 Compared with compression crushing, impact crushing will create more fines within the circuit, which will cause greater wear if processing abrasive material This is why rocks with lower silica content are more suited to reduction by impact crushers When compared with cone crushers, impact crushers often have a lower capital cost, but can Understanding Comminution: Compression versus impact crushing2022年3月23日 Size reduction is a process in which particles with smaller size and large surface areas are formed, which ultimately eases the processing The chapter explains the size reduction mechanism during compression, impact, cutting, shearing, and attrition The stressstrain behavior of materials during mechanical failure also plays an important role Size Reduction SpringerLink