Crushing And Separation Of The Ore

2021-06-07T02:06:22+00:00

Comminution and classification technologies of iron ore

2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for 2022年7月31日 Advances in the mineral processing steps are constant Crushing develops more efficient particle breaking, avoiding fine particles, and optimizing energy Special Issue "Advances in Ore Processing Technologies: Crushing 2017年3月7日 The processing like crushing will disintegrate and unlock the values from the waste, so that the methods of separation will be able to (PDF) ORE SEPARATION BY CLASSIFICATION

OVERVIEW OF MINERAL PROCESSING METHODS

17 小时之前 The fundamental operations of oredressing processes are: a) the breaking apart of the associated constituents of the ore by mechanical methods and b) the 2017年3月4日 It is a process of ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals(PDF) SIZE REDUCTION BY CRUSHING METHODS2015年9月10日 Metallic mineral processing typically involves the mining of ore from either open pit or underground mines; the crushing and grinding of ore; the separation of 1124 Metallic Minerals Processing US EPA

Effect of a Crushing Technique on Lead–Zinc Ore Processing

2018年4月16日 Conditions of preparation and separation of disintegration products are described The authors illustrate the change in the dissociation selectivity criterion in jaw 2020年3月26日 The iron in magnesite ore includes the iron in the raw ore and the iron impurities entrapped in the crushing process The iron entrapped in the crushing and grinding can be partially removed by The Flotation Separation of Magnesite and 2022年11月18日 Comminution: Crushing and Grinding NRRI possesses several crushing and grinding techniques at the bench and pilot scale: Crushing Jaw crushing; Gyratory Mineral Separation Natural Resources Research Institute

The Flotation Separation of Magnesite and

2020年3月26日 The iron in magnesite ore includes the iron in the raw ore and the iron impurities entrapped in the crushing process The iron entrapped in the crushing and grinding can be partially removed by 2018年1月12日 iii Magnetic Separation – separation based upon natural or induced differences in magnetic susceptibility of the minerals within the ore iv Froth Flotation – separations based on the surface chemistry Introduction to Mineral Processing or 2015年9月10日 As the iron ore minerals are liberated by the crushing steps, the ironbearing particles must be concentrated Because only about 33 percent of the crude taconite becomes a shippable product for iron making, a large amount of gangue is generated Magnetic separation and flotation are the most commonly used methods for 1123 Taconite Ore Processing US EPA

Mineral Comminution and Separation Systems EOLSS

2020年8月25日 Raw ore, or ‘runofmine ore’, is received by the storage 1 of the crushing plant for temporary storage, and then discharged through the feeder 2 for controlled rate of supply to the primary crusher 3, where coarse particles included are broken The broken ore is conveyed to the secondary crusher 5 for further stage of crushing2023年5月18日 Crushing is typically done using jaw crushers or cone crushers 7Grinding and Magnetic Separation: The crushed iron ore is then ground to a fine powder in ball millsHow is iron mined and refined? LinkedIn2 天之前 Crushing and drying are slightly different, as crushing involves a drying process On the other hand, grinding is a wet process Sizing After crushing and grinding, the next step is sizing these materials As the name suggests, sizing is the process of the separation of particles based on their sizeMineral beneficiation and ore dressing Unacademy

Minerals Free FullText Study on Quantitative Separation

2023年4月6日 Based on batch grinding method and normalization idea, a conical ball mill is used and a quantitative separation method of grinding characteristics of multicomponent complex ore is proposed The results show that the feed sizes of polymetallic complex ore have an obvious influence on the particle size distribution of intermediate grinding 2020年2月13日 Gravity separation was effective in the size fraction 40%) and that the rest of the ore mineral occurs in mixed particles where niobium and tantalum minerals make up >50 volume % of the particleUnderstanding Mineral Liberation during Crushing Using 2022年3月21日 Geology, deposit types, and ore minerals There are more than 200 minerals that contain REE 7,8 The most common rareearth minerals are monazite and bastnäsite (Figure 1a–b and Table II)Monazite exists as a group of arsenates, phosphates, and silicates, but the primary REEbearing monazite is a complex phosphate 5 Processing the ores of rareearth elements SpringerLink

How to Extract Iron from Hematite: Methods and Plants

2023年2月15日 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation Mediumgrained hematite refers to iron ore with an embedded particle size between 002 and 2mm This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roasting2017年4月10日 Electrostatic separation also is employed sometimes, principally in dressing nonmetallic minerals In general, cyanide treatment comprises four steps—preparation of the ore (crushing, screening, grinding, and classification), leaching or dissolving the gold, separation of the goldbearing (“pregnant”) solution from the leached Ore Dressing Methods 911 MetallurgistSix steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents overloading the crusher and increases its efficiencyThe six main steps of iron ore processing Multotec

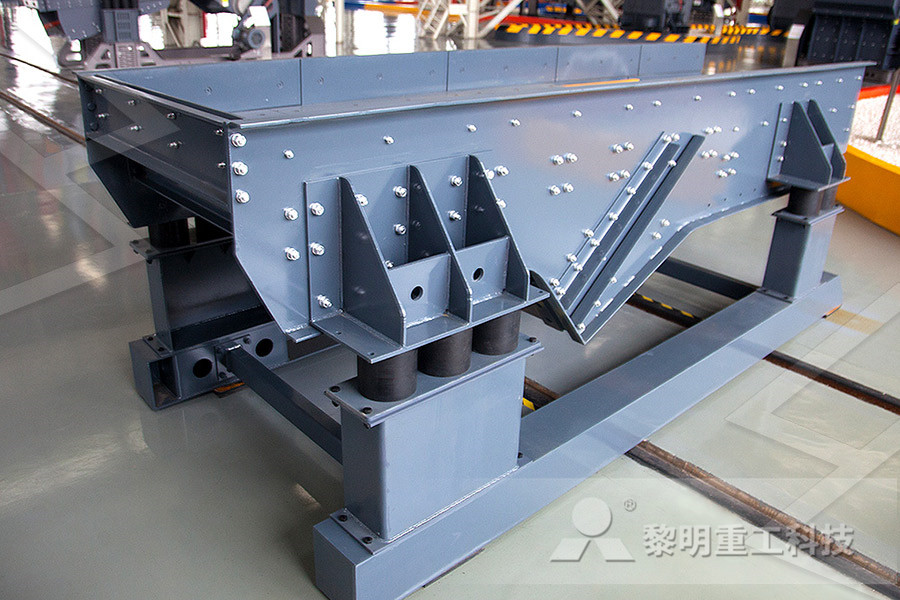

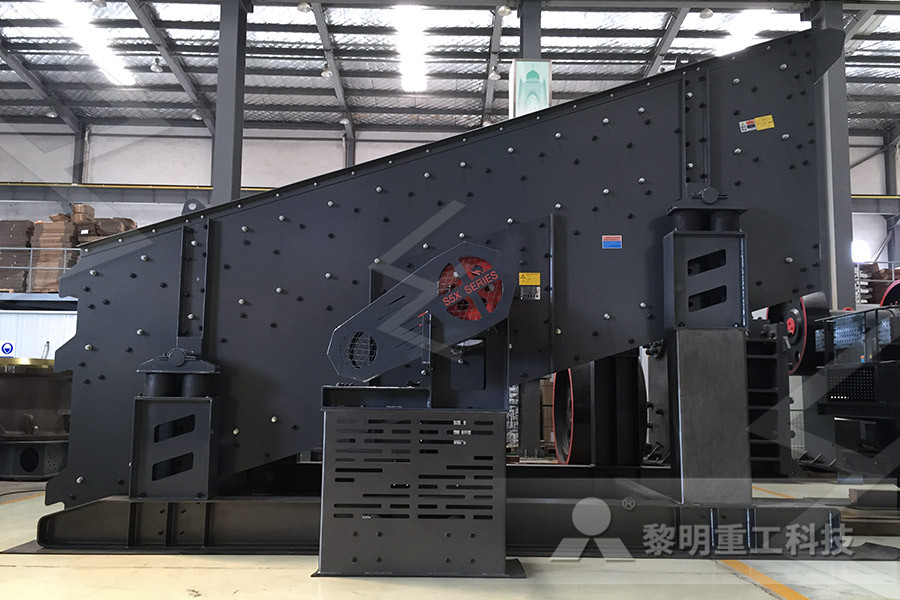

Magnesite Ore Processing: Separation and

2023年5月12日 The processing flow is as follows: 1 Crushing: Use a jaw crusher, roll crusher, and vibrating screen to form a twostageclosed circuit crushing system to crush the raw magnesite ore to 1mm 2 Calcination: Magnetic separation can remove magnetic gangue minerals or in the case of iron ore mining to separate the magnetic ore mineral into a concentrate of magnetite (Fe 3 O 4) Gravity separation uses density differences to separate heavier minerals from lighter Gold panning is a method of gravity separation, where gravel and sand from a river is Chapter 2: An introduction to mining SGU2022年4月3日 Cont’d 1 CRUSHING AND PULVERIZATION The ore is generally obtained as big rock pieces These big lumps of the ore are crushed to smaller pieces by using jaw crushers and grinders (fine and coarse stages ) It is easier to work with crushed ore The big lumps of the ore are brought in between the plates of a crusher forming a jawCHAPTER 3 MINERALS ORES AND METHODES OF SEPARATION

Concentration of Ore: Definition, Classification, Methods

2023年1月25日 Hydraulic Washing: This method concentrates the ore by passing it through an upward stream of water whereby all the lighter particles of gangue are separated from the heavier metal ore This is a type of gravity separation Magnetic Separation:This involves the use of magnetic properties of either the ore or the gangue to separate them 2017年8月23日 Metal Ore Extraction and Processing 173 Although other nonferrous metals have lower melting points than aluminum, and can therefore be processed at somewhat lower temperatures, the same process steps tend to be used: crushing, grinding, concentration by flotation or other means, smelting, refining, and electrolytic purificationMetal Ore Extraction and Processing Springer2020年8月25日 Raw ore, or ‘runofmine ore’, is received by the storage 1 of the crushing plant for temporary storage, and then discharged through the feeder 2 for controlled rate of supply to the primary crusher 3, where coarse particles included are broken The broken ore is conveyed to the secondary crusher 5 for further stage of crushingMineral Comminution and Separation Systems EOLSS

Mineral Processing an overview ScienceDirect Topics

The journey from ROM ore to concentrate and finally metal travels through many operations of liberation, separation, concentration, and extraction before it reaches the end users These activities have been diagrammatically summarized in Figs 1353 and 1354 A panoramic view of State of the Art zinc and lead smelting is depicted in Fig 135511531 Beneficiation Mineral beneficiation begins with crushing and grinding of mined ore for nearcomplete separation of ore and gangue minerals as well as between ore minerals Each processing step is designed to increase the grade (concentration) of the valuable components of the original oreBeneficiation an overview ScienceDirect Topics