Cement Raw Material Grinding Greg Rock Crusher Machine

2023-02-20T18:02:12+00:00

The technics of Cement production process Rock Crusher

In the technics of Cement production process, People usually choose limestones and clays as the main raw materials, crushing, concocting, grinding them into cement raw meal, Vertical raw material grinding has been widely used in dry process cement plants The raw material preparation system of the 2 500 t/d cement production line can adopt the vertical mill with the disc diameter of 3 400 Raw Material Preparation in Cement 2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller Review on vertical roller mill in cement industry its

Cement grinding optimisation ScienceDirect

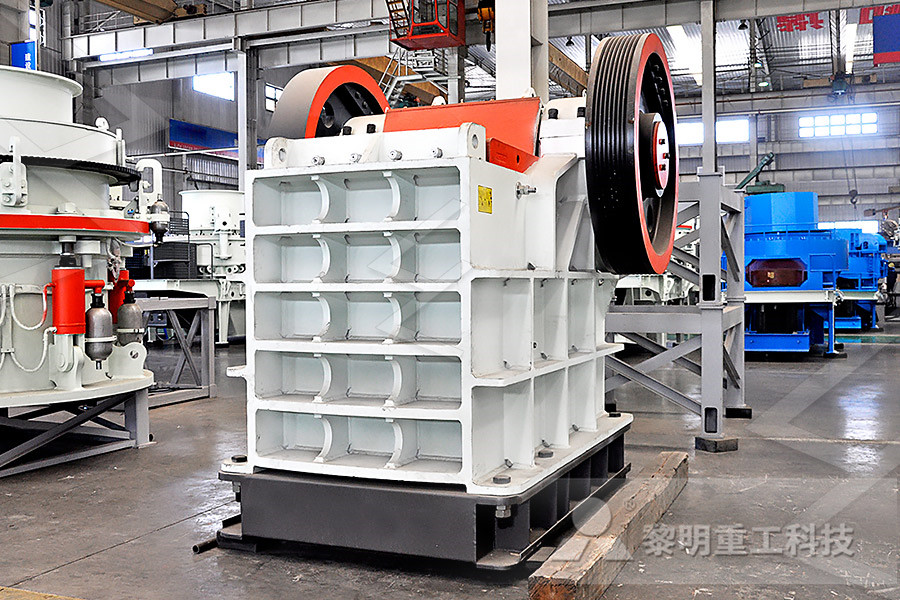

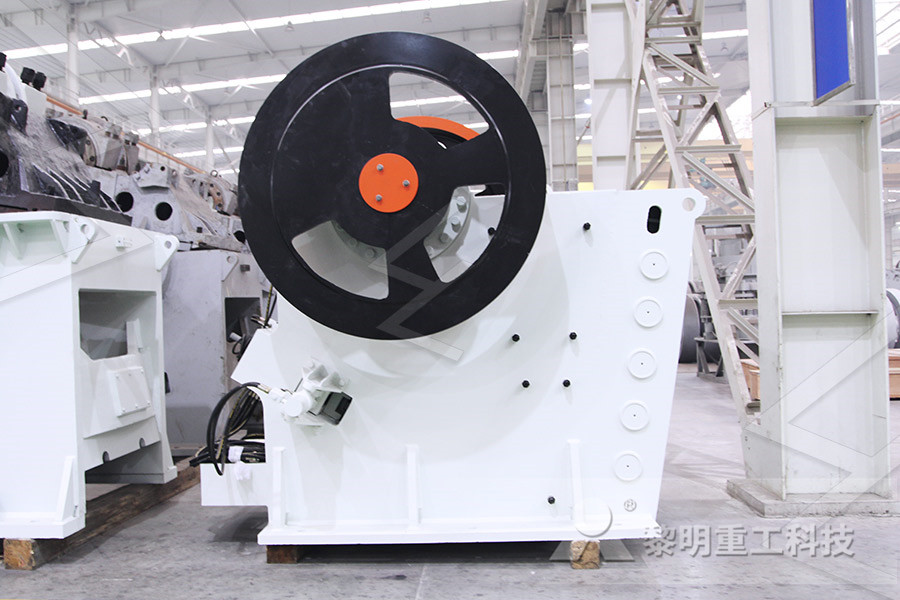

2004年11月1日 Introduction For all dry grinding applications, cement production is certainly the most important The estimate for the world energy consumption for cement Cement hammer crusher, also called hammer crusher machine, as a cement crusher, can be used for raw material production of cement plants Apply for coal, salt, gypsum, alums, brick, tile, limestone and etcHammer Crusher Machine Hammer CrusherCrusher is a kind of machinery that is widely used in the cement production industry It is mainly used in the material preparation process to crush the raw materials into proper Cement Crusher Crushers for Cement Plant AGICO Cement

Cement Crusher – Crusher In Cement Plant

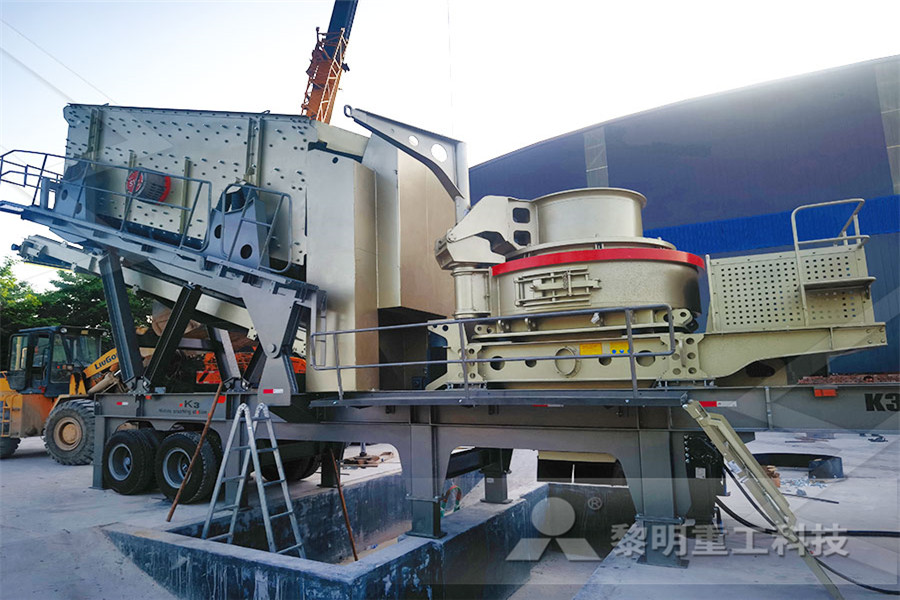

As a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a series of cement crushers required for cement raw 2012年2月21日 The primary raw materials used inside the cement manufacturing process are limestone, sand, shale, clay, and iron ore The main material, limestone, is generally Raw Material Preparation for Cement Crushing CSDN博客The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing: the limestone and other materials are Preparation Of Cement Raw Material Cement Mill, Cement Crusher

Modeling of energy consumption factors for an industrial cement

2022年5月9日 The raw materials are crushed in a hammer crusher to D 95 80 mm The raw materials were mixed in a certain proportion and fed into a vertical roller mill The cement raw materials is formed with calcareous materials, clayey materials and slight corrective material in appropriate proportion, and grinded into certain fineness The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing: the limestone and other materials are Preparation Of Cement Raw Material Cement Mill, Cement Crusher2023年2月16日 Some common types of crushing equipment used in cement production include: Jaw Crushers: These are typically used for primary crushing of large chunks of raw materials such as limestone, clay, and What kind of crushing equipment is needed to produce cement

From raw materials Extracting raw materials Raw

2022年2月12日 Raw material preparation II: Drying and raw grinding Burning The burning of the raw meal at approx 1,450°C is carried out in Lepol or preheater kilns that work by varying methods, the main difference being in the preparation and preheating of the kiln feed By chemical conversion, a process known as sintering, a new product is formed: Crusher machines come in a wide variety of sizes and capacities, from small jaw crushers that cost the same as a new truck to extra large cone crushers that cost millions of dollars patented, and sold the first actual rock crusher in 1858, it was known as the Blake Jaw Crusher Blake’s crusher was so influential that today’s models are Types of Crushers: What You Need to Know Machinery 2023年1月9日 4Calculate the production capacity To calculate the production capacity, you need to multiply the volume of the crusher by the density of the material and the desired output size For example how to calculate stone crusher production LinkedIn

China Crusher, Crusher Manufacturers, Suppliers, Price

1 Set (MOQ) Top Quality PE (X) Stone Rock Jaw Crusher of Mining Machine BRIEF INTRODUCTION The Jaw crusher is used for the crushing of raw materials in metallurgy, architecture, road WUYI SLON MACHINERY CO, LTD Contact Now Inquiry Basket 1 / 6 China Manufacturer of Crusher2004年11月1日 Grinding occurs at the beginning and the end of the cement making process Approximately 15 tonnes of raw materials are required to produce 1 tonne of finished cement The electrical energy consumed in the cement making process is in order of 110 kWh/tonne and about 30% of which is used for the raw materials preparation and Cement grinding optimisation ScienceDirect2023年5月27日 The answer is the cement industry Limestone plays two major roles in the cement manufacturing process, one is used as a raw material for cement clinker, and the other is used as a cement admixture Limestone is one of the key raw materials of cement clinker Around 8090% of the raw material for the kiln feed is limestone2 Major Roles of Limestone in Cement Manufacturing

Drawings Of Ball Mill Crusher Mills, Cone Crusher, Jaw

Rock Crusher Series Tire Type Mobile Crusher Crawler Type Mobile Crusher JCE Jaw Crusher Flywheel Grinding Machine; CONE CRUSHER BRITAGEM; Mls3726 Vrm Stone Crusher Machine Europe; Wikipedia, the free encyclopedia In general, cement raw materials are mainly quarried, using about half the energy of a ball mill, and there 2 Process Of Manufacture Of Cement Wet Process Dry Process The crushing and pulverizing process is carried out separately for each material After grinding, each of the materials is stored in hoppers 2 Mixing Storage The raw materials are then mixed in correct proportions in dry powdered form with the help of compressed air This finely cement raw material grinding greg rock crusher machineThe roller crushers are used for moist and sticky materials Generally the machines have to be rigid enough to crush also hard inclusions As the reduction ratio is only about 5:1 a 2stage crushing is required in most applications Fast running type crushers like hammer and impact crushers are the simplest and cheapest solution, whenever the Everything you need to know about Crushers in Cement

Pfeiffer Mps 5000b Roller Mill Crusher Mills

Pfeiffer AG will supply the whole plant, 3 MPS vertical roller mills for Hoa Phat Cement, Vietnam Applications of GEBR PFEIFFER technology in the lime industry Fig 3: Pfeiffer MPS 140 B vertical roller mill for quicklime grinding, Saudi Arabia Fig 4: Flow sheet of a quicklime grinding plant with MPS vertical roller mill2023年3月1日 A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials The crushed material is then used as an input into the Why is a crusher section used in the cement industry?2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials The overall grinding circuit efficiency and stability are improved The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended 25EnergyEfficient Technologies in Cement Grinding IntechOpen

Crusher an overview ScienceDirect Topics

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The 1971年8月17日 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of 116 Portland Cement Manufacturing US EPALoesche – Grinding Mills for Ores and Minerals – Mining Loesche has more than 100 years of experience in the comminution of cement and raw material, clinker, coal, slag and minerals Loesche mills have been successfully Loesche Cement Mill Crusher Mills, Cone Crusher, Jaw

Rock Crusher Eastman Rock Crusher

Eastmancrushing understands crushing and grinding machines well We are one of the leaders in rock crushing in China for about 40 years We’re proud to offer a line of rock crushers that provide a wide range of options and fit a variety of applications From reducing the size of large rocks to gravel, grinding rocks to table salt size, or 2016年1月20日 1 Introduction Over the last century, Portland cementbased concrete has become the highest manufactured product on Earth in terms of volume Concrete is used worldwide as a building material and is the most consumed substance on Earth after water (Sakai, 2009)The volume of concrete produced globally is approximately 530 billion m 3 Analysis of material flow and consumption in cement production