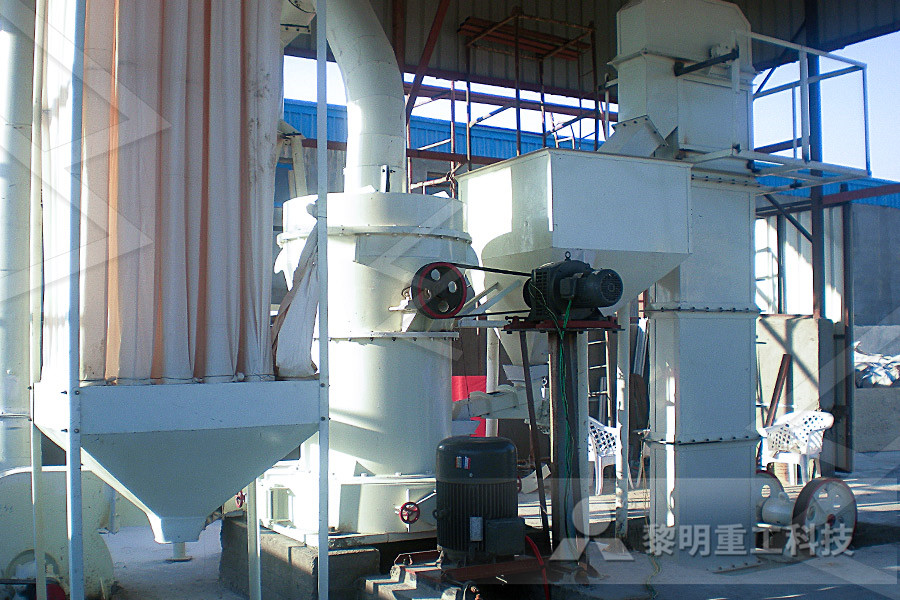

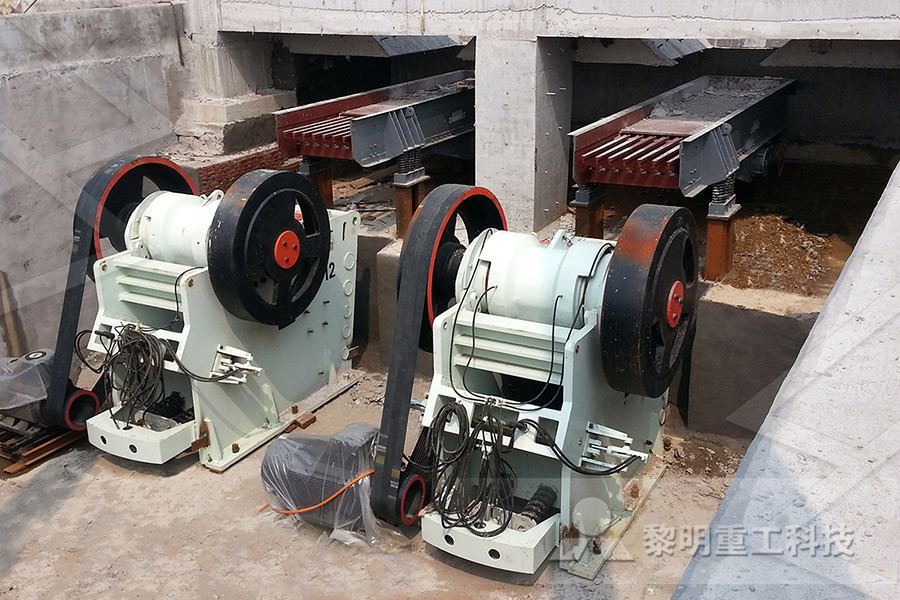

Roller Mill Installation Sequence

2023-07-14T19:07:15+00:00

Roller type vertical mill installation method Semantic Scholar

The installation sequence comprises the following steps: positioning a vertical mill pedestal, installing a basic framework, installing a pedestal, installing a bridge frame, secondary 1996年4月18日 Selection and installation of a vertical roller mill for clinker pregrinding Abstract: Roller presses have become well established as a method for increasing the Selection and installation of a vertical roller mill for clinker 2011年9月14日 This article describes a scientific design procedure that begins from a given product mix to a customized rolling mill The (PDF) A JOURNEY TO OPTIMAL ROLLING MILL

(PDF) On the Optimization Procedure of Rolling

2012年9月27日 Mechanical aspects include roll bending, roll shifting, hydraulic force cylinders, hydraulic systems, thermal crown, quick roll 2012年12月31日 PDF a Distributed Control System(DCS) of cement raw materials is presented for the vertical roller mill by the application of (PDF) Design and Realization Of Roller Mill 2019年2月21日 The purpose of the study was to analyze and evaluate technical conditions of use of a roller mill with a new design (UPRP P and EP) of the roller A study of operating parameters of a roller mill with a new

Design and Realization Of Roller Mill Control System

2023年10月4日 University of Jinan Jinan, China Email: ; zhanghongyu@163 Abstract Distributed Control System(DCS) of cement 2021年3月1日 Quick design of new mill constructions, in particular for roller ones, requires the development of adequate mathematical models Within the frames of the study, a mathematical model of loading of the bowl Selected Aspects of Modelling and Design 2022年4月4日 Accelerated onsite installation With its large number of preassembled components, quadropol mill equipment is designed for smooth onsite installation The VERTICAL ROLLER MILLS A holistic VRM approach

Chapter 7 Roller Milling of Wheat ScienceDirect

2007年1月1日 In the case of wheat, the roller milling process tends to open up the initially compact wheat kernel to create large bran flakes along with finer endosperm material 2017年10月27日 Figure1 Vertical roller mill for cement grinding [13] VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal revolving grinding table To enhance comminution, the axes of table and rollers do not traverse in the plane of the table and approximately 150 inclination angles betweenPROCESS CONTROL FOR CEMENT GRINDING IN 2021年2月10日 Operationin feedmill: In the feed mill operations include all the procedures which are helpful to increase the quality of feed Mixing: – It is done by mixer Mixers are two types:Horizontal mixer ii Vertical mixer LAYOUT AND OPERATION OF FEED MILL

(PDF) Method of load calculation of electrical

2018年5月1日 Problems concerning reduction of the dynamic loads on the horizontal and vertical rolls of universal rollingmill stands are examined The unacceptably large shock loads that develop in the 2023年9月25日 Step 4: Install the new roller rocker arms for number 1 cylinder with the flat area on the trunnion shaft up Step 5: Make sure the rocker does not bottom on the rocker stud radius Check clearance through the entire lift range Check rocker arm geometry You may need to change pushrod length to achieve proper geometryM6564ALL Roller Rocker Arms INSTRUCTION SHEETThe method of the invention is capable of acquiring a lot of important construction technical data, and accumulating valuable experience for installing subsequent same kind equipments The invention relates to a roller type vertical mill installation method, which belongs to the mechanical equipment installation method The installation sequence Roller type vertical mill installation method Semantic Scholar

W11F Three Roller Roll Bending Machine: Expert Guide

2023年7月26日 Also confirm that the movement of the lower rollers and upper roller is correct) 6 Installation and Debugging of Roll Bending Machine The ground plane and slope level in any direction must not exceed 2 mm/m Before installation, inspect the machine to ensure it is in good working condition and prepare thoroughly2022年4月4日 Accelerated onsite installation With its large number of preassembled components, quadropol mill equipment is designed for smooth onsite installation The weight of the four preassembled roller units of a mediumsized mill (approximately 450tph) is around 50 per cent of the total weight of the mill and separatorVERTICAL ROLLER MILLS A holistic VRM approach\n \n \n grinding china markets \n \n \n recycled crushed concrete prices melbourne \n \n \n 3 lb ball mill machine solution for mining quarryGitHub: Let’s build from here GitHub

GitHub: Let’s build from here GitHub

Roller Mills Milling Group Our roller mills consistently and safely grind wheat,corn,rye,barley,spelt and other grains We offer a wide range of roller mills and optional functions to match the milling solutions you need + Product range Explore our range of roller, roller crusherfeldspar ficci fipic roller mill fluting 2015年11月19日 2 Principles and Applications of Metal Rolling (ii) Shape of the rolled product flat, sections or hollow sections rolling (iii) Direction of rolling lengthwise, transverse, and skew rolling (iv) Mode of rolling mill operation continuous (unidirectional), and reverse rolling, where direction of rotation of rolls are reversed When two rolls of Introduction to Rolling Process Cambridge University 2019年7月23日 3 All mills are equipped with shielding to protect the operator from injury For purposes of clarity only, some illustrations in this manual show the hammer mill with the shields removed or missing Although shields may be opened or removed for servicing and repair of the hammer mill, they MUST always be closed or replaced before operation OPERATOR, PARTS INSTALLATION MANUAL

Operating Instructions for Installation, Use and Maintenance of Roller

2022年5月17日 Operating Instructions for Installation, Use and Maintenance of Roller Bearings in Rolling Mills helpline: +852 and then install it into the bearing seat in sequence; 3 Add an appropriate amount of grease between the bearing shell and the rolling elements (usually 2/3 of the limited space between the bearing parts); 2023年10月4日 The mill process is cement freestanding roller grinding raw coupling between the most comple QianHong Wang et al / Physics Procedia 33 ( 2012 ) 437 – 443 441 x systemDesign and Realization Of Roller Mill Control System2001年10月1日 A cement Vertical Roller Mill modeling based on the number of breakages It is used to grind slag, nonmetallic ore, and other block and granular raw materials into the fine powders necessary for production In the mid1990s, Loesche GmbH developed the VRM technology, which was first used for grinding clinker and slag [3]Loesche vertical roller mills for the comminution of ores and minerals

Design and Realization Of Roller Mill Control System

2012年1月1日 DCS process control system standing roller grinding Physics Procedia 33 ( 2012 ) 437 – 443 18753892 2012 Published by Elsevier BV Selection and/or peer review under responsibility of ICMPBE International Committee doi: 101016/jphpro201205086 2012 International Conference on Medical Physics and Biomedical Engineering Design and2018年10月24日 First, install the pushrods and torque all the rocker arm bolts down in the proper sequence and proper torque specification Rotate the engine by hand in the normal direction of engine rotation until both the exhaust and intake valves have opened and closed completely Allow a couple of minutes for the lifters to bleed downINSTRUCTIONS COMP CamsSquaring and alignment of the workpiece, proper blocking of the bearing and shaft, and slow, even pressure are required Lower the ram slowly and observe where the force is being applied The same person should insert/set up the work and operate the press Do not exceed the working load limit of the pressBearing installation and removal basics Processing Magazine

StepbyStep Guide to Plate Rolling Machine Operation

2023年7月24日 Rolling circular: Apply a continuous pressure of 15mm on the upper roller’s outer circle against the plate’s surface Control the rotation of the bottom roller using a jog control Stop the rotation of the bottom roller when the plate’s arc length reaches 600800mm Apply a pressure of 10mm on the upper roller, rotate the bottom roller 2021年3月1日 An analysis of construction was conducted in this study, and the guidelines for designing roller mills used commonly in the agrifood, chemical, power and construction industries were presented Quick designing of the machines required existence of adequate mathematical models Within the framework of the study’s realization, a mathematical Selected Aspects of Modelling and Design Calculations of Roller MillsHighpressure piping will be made of pipe steel, in order to connect pipe flow to the valves for descaling and complete with heavyduty PP clamps, fittings, hoses, etc Descaling speed on the liner = 15–4 m/sec Water descaling unit operates according to the required rolling speed/ mill capacity MODEL 2Water descaling unit for rolling mill ENCE