Working Principle Of Coal Handling Plant Ball Mill

2023-04-18T15:04:48+00:00

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011年1月1日 Compared with actual situation of the current thermal power plant, this paper studies operation process of coal handling system in thermal power plant Analyze 2014年4月1日 Tubeball mill is another dominant type of coal mill apart from Vertical Spindle mill in industry Compared with the Vertical Spindle mills, Tubeball mills have a A new modelbased approach for power plant Tubeball mill Contribute to dihog/ development by creating an account on GitHub/ working principle of coal handling plant ball mill

Coal Pulverizer – Power Plant Pall Corporation

2023年10月4日 BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal, 2020年5月13日 Ball mill; Hammermill; Bowl mill; Ball and Race Mill Pulverisation coal involves the following: Drying the coal; Grinding the coal; Separation of desired size coal particles Advantages of Pulverised Coal Coal Handling Plant Layout Thermal Power Ball mills are commonly used for crushing and grinding the materials into an extremely fine form The ball mill contains a hollow cylindrical shell that rotates about its axis This Ball Mill an overview ScienceDirect Topics

Mills In Coal Handling Plant Crusher Mills

working principle of coal handling plant ball mill As a professional crushing and grinding equipments manufacturer, liming can supply you all kinds of machinery for you coal 2019年11月7日 Abstract and Figures Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main (PDF) Optimization and transformation of 300MV units steel ball coal 2017年1月5日 The raw coal is pulverized in the vertical cylindrical mill, and the pulverized coal is lifted to a powder separator by another bucket elevator The powder separator consists of a centrifugal rotor, 6 cyclones and a selfrecycling pneumatic system Large size particles return to the mill, and fine powder is collected by cyclones and thenCoal Pulverization System: Explosion Prevention and

Power Plant Engineering Laboratory Manual Course

2019年6月26日 The various pulverising mills used are as follows: 1 Ball mill 2 Hammer mill 3 Ball and race mill 4 Bowl mill The essential functions of pulverising mills are as follows: 1 Drying of the coal 2 Grinding 3 Separation of particles of the desired size The coal pulverising mills reduce coal to powder form by three actions as follows: 12023年10月4日 The four most common coal pulverizers types are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the Coal Pulverizer – Power Plant Pall Corporation1 天前 Reagent Preparation System The reagent preparation system of flue gas desulfurization (FGD) includes a Wet ball mill and cyclone classifiers which produce a finely ground limestone slurry at 90% solids passing through 325 mesh One mill slurry tank and one slurry pump is supplied for one wet ball mill The mill slurry pump will send limestone Flue Gas Desulfurization (FGD) Working Thermal Power Plant

Dynamic classifiers improve pulverizer performance and more

2007年7月15日 JB Sims Power Plant in Grand Haven, Mich Dynamic classifiers were retrofitted to three B’W Model EL56 ball mill pulverizers feeding an 83MW B’W frontwallfired boiler As at Tilbury Power Coal Ball Mill Feeding size: ≤25mm Capacity: 520t/h Functional advantages: Less failure and reliable operation Applications: It is mainly used for grinding coal of various hardnesses, and is also suitable for coal powder making system and ore milling system in cement plants and metal magnesium plants : Ball Mill Grinding for Different Kinds of Pulverized Coal2021年8月20日 The structure of the single roll crusher is shown in Figure 3 The crushing mechanism consists of a rotating roll 1 and a jaw plate 4 The jaws are mounted on a bolt with a tooth bushing 2 on the core of the roll, with the tip of the tooth sticking forward like a hawk’s beak, which can be removed and replaced when the bushing wears outRoll crusher working principle Henan Deya Machinery Co,

Coal mill pulverizer in thermal power plants PPT SlideShare

2012年11月16日 20131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill Quantum Nanostructures (QDs): An Overview D Sumanth Kumar, HM Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3611 Ball Milling A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball Ball Mill an overview ScienceDirect Topics2023年4月20日 Coal mill is a kind of ball mill, which is often used to crush and grind coal bricks into powder As the main equipment in the cement plant, it can be used for the milling of coal Therefore, it is also called Coal Mill with Industrial Solutions Fote

en/coal crusher and mills working principlemd at main

英语网站资料 Contribute to boy/en development by creating an account on GitHub2013年9月2日 Simple and sound, requiring minimum operations and transportation 2 No double handling of coal in plant 3 Handling unit should be centralized to facilitate inspection and maintenance 4 Electric motors Coal and Ash Handling PPT SlideShare2014年4月1日 The working principle of the coal mill is illustrated in Fig 1 [25]In normal practice, there are two coal feeders for each mill Once the raw coal flows into the mill barrel with hot primary air, the iron balls inside the rotating barrel will continuously crash the coal until it is fine enough to be blown out the mill to the furnaceA new modelbased approach for power plant Tubeball mill

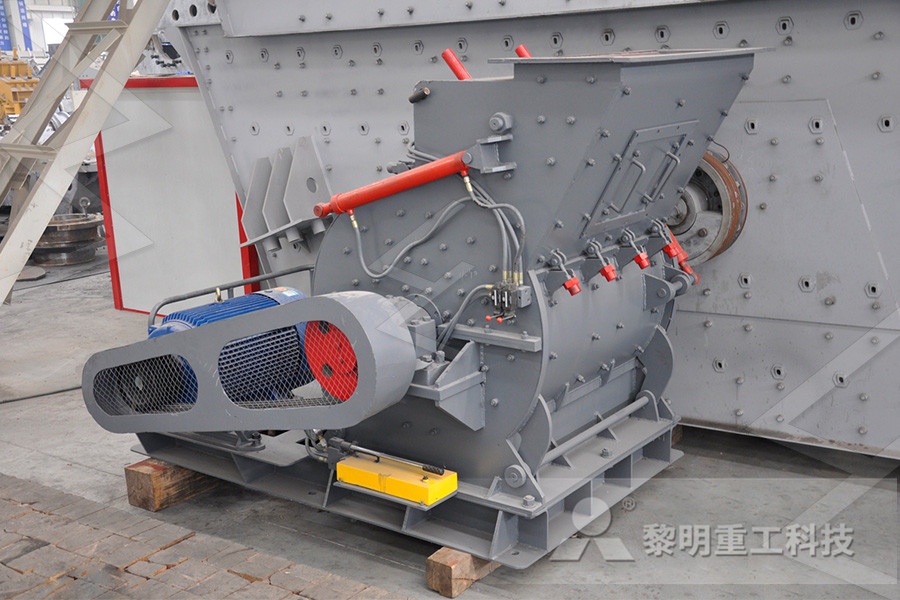

Cement Roller Press Roller Press In Cement Plant Roller

Cement Roller Press Model: G Type Output: 290 – 1580 t/h Power: 2×250 – 2×1800 kw Certification: ISO9001 SEND INQUIRY The cement roller press is a kind of grinding equipment applied for brittle materials, such as cement clinker, granular blast furnace slag, cement raw materials (limestone, sandstone, shale, etc), gypsum, coal 2015年10月1日 The ball tube mill requires less mass flow rate of primary air and raw coal per MW of power produced than the bowl mill It contains larger mass of raw and pulverized coal but less grinding heat (PDF) Control for pulverized fuel coal mill ResearchGateimpact crusher animation – crusher mining – kefid machinery this is the impact crusher detailed working procedures and other issues about the crusher you can check the entire coal pulveriser ball mills animation Coal Impacter Working Animation Crusher Mills

Modeling of Coal Mill System Used for Fault Simulation

2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples In order to obtain massive fault sample data 2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can be classified into to two basic types, crushers and grinders Industrial crushers are the first level of size reducer; further granularization How it Works: Crushers, Grinding Mills and PulverizersThey are designed both to reduce the size of large coal lumps to less than 6–14 in (15–36 cm), and also to feed materials out of bins and onto conveyors or chutes Conventional singleroll crushers use a simpler toothedroll design, and are commonly used to reduce coal to approximately a 2–3in (5–8 cm) top sizeRoll Crusher an overview ScienceDirect Topics