Crusher With Capacity Of Crushing T How To Use A Rock Crusher

2020-10-20T07:10:45+00:00

How Does a Rock Crusher Work? Sciencing

2017年4月24日 Most rock crushers have a hopper at the top a container which holds the rock above the crusher and uses gravity to feed it in 2015年12月16日 For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between these capacities, Rock Crushing Rule of Thumb 911 Metallurgist2021年6月21日 Purpose The purpose of the Rock Crusher model is to visualize ALL the work required to go from “concept to cash,” not just the work of coding Often the work Rock Crusher Guidance Article International Institute of

Crushing 101 – Different types of crushers for

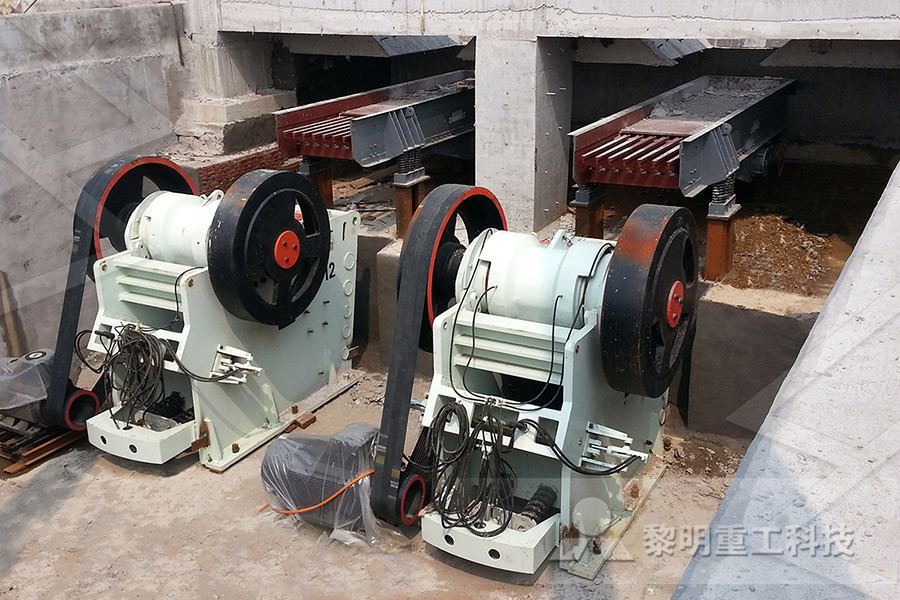

2020年12月17日 All rock crushers can be classified as falling into two main groups Compressive crushers that press the material until it breaks, and impact crushers that use the principle of quick impacts to crush the 2021年11月22日 How does a Rock Crusher Work – Jaw Crusher Jaw crushers include Superior, Type “B” Blake, FineReduction, and Dodge — sizes, 4 by 6 to 84 by 66 How does a Rock Crusher Work Jaw Crusher 911 They have a higher capacity than comparable singleroll crushers For example, a tworoll crusher with 24inchlong (61 cm) rolls crushing to ¾ inch (2 cm) has a capacity of 75 Roll Crusher an overview ScienceDirect Topics

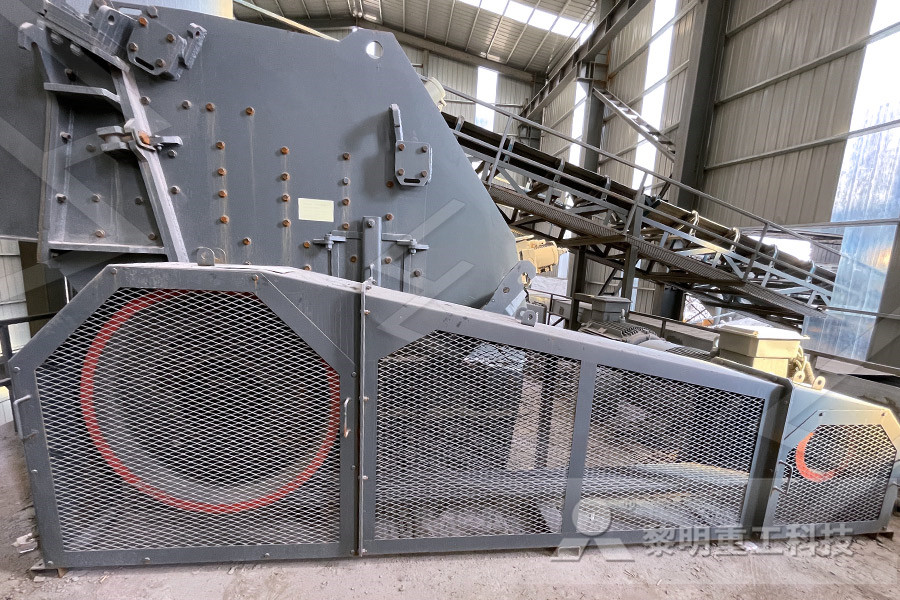

Crushers All crusher types for your reduction needs

Offering Crushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in mining 2022年8月21日 All the enterprises of metallurgical industry produce and use crushed materials obtained by crushing The share of produced energy spent on crushing is more Capacity Calculations of the Crasher with Stops on a Roll2023年10月3日 The capacity (throughput) You will need to determine the processing capacity (or throughput) necessary for your use This is measured in tonnes/hour You Choosing the right crusher Buying Guides DirectIndustry

Roll Crushers ScienceDirect

2016年1月1日 The roll size of a roll crusher was 305 cm × 901 cm Gypsum rock (SG = 27, bulk density = 17 t/m 3) is to be crushed Determine 1 the set in order to crush at the rate of 12 t/h and 10 rpm speed of the rolls, 2 the ratio between capacity and peripheral speed if the set was 25 cm, 3 the nip angle when the crusher feed size is 10 cm,2020年3月19日 Aggregate quality is measured in terms of product gradation, particle shape and mechanical properties Feed gradation, crusher setting and crusher speed affects the specific energy (PDF) Influence of jaw crusher parameters on the Impact Crusher Capacity 350 tph 385 TPH: RM 100GO! Impact Crusher Capacity 250 tph 275 TPH: RM 90GO! Impact Crusher Capacity 200 tph 220 TPH: RM 70GO! 20 If you don't have reliable rock crushing Mobile Rock Crushers Performance Simplicity

How Do I Know Which Primary Crusher Is Best For My Coal

2019年10月17日 Generally, a Quad Roll Crusher is recommended for a medium size feed material, while the Triple Roll Crusher, with its single roll top stage, is effective for handling larger size feeds These machines do the work normally assigned to two separate crushers Typical feed sizes range from 18” – 72” with final product size of ½” – 3”2016年7月8日 By referring to equipment manufacturer’s bulletin on crushers, Fig 1, a crusher producing 80% passing 3/4″ requires a close side setting of approximately 5/8″ Since the selected crusher capacity must be in excess of 143 tons per hour, the next higher figure (159) is chosen The 159 indicates a 548 crusher size with 1″ eccentric throwEquipment Sizing: Crusher or Grinding Mill 911 Metallurgist2021年8月13日 In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing torque, and crushing power A novel polar (PDF) Torque Analysis of a Gyratory Crusher with the

Simulation and optimization of gyratory crusher

2020年10月1日 1 Introduction The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]]In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues 2022年11月21日 Throughput [t/h] 0 Crushing capacity • with primary screening • high fines content CSS jaw opening [mm] EB 1210 H EB 1411 H EB 1612 H EB 2015 H Average throughput rate of singletoggle jaw crusher, hardrock version, tolerance ± 10% 100 150 swing jaw moves forward Serrated jaw plates enhance the crushing processIndustrial Solutions Jaw crushers ThyssenKrupp2020年6月1日 The crusher and feed parameters used are closed side setting ( CSS ), speed, feed rate and feed gradation This paper presents a parameter study investigating the effect of feed and jaw crusher parameters on the quality of aggregates produced from singlestage crushing The parameter study is evaluated using mechanical and Influence of jaw crusher parameters on the quality of

(PDF) Design and Construction of Rock Crushing Machine

2018年8月7日 The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals 2015年12月16日 For example, a 48 by 60 crusher will have a capacity in the order of 600 tph when crushing ore in a hard rock mine Source: Jack de la Vergne; The capacity of a jaw crusher selected for underground service should be sufficient to crush the daily requirement in 12 hours Source: Dejan Polak For most applications, 7:1 is the maximum practical Rock Crushing Rule of Thumb 911 MetallurgistMechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer Crusher an overview ScienceDirect Topics

How many tons per hour of rock crusher LinkedIn

2023年2月23日 The capacity of a rock crusher depends on several factors, including the type of rock, the size of the feed material, the desired product size, and the operating conditions For example, a small Figure 1 Kinematical scheme and kinematic parameters of singletoggle jaw crusher 3 Capacity determination methods To date, many theoretical, empirical and semiempirical dependencies for approximate evaluation of a singletoggle jaw crusher capacity have been proposed The generalization of these dependencies is proposed in [17]RIVLQJOH WRJJOHMDZ FUXVKHU 2021年11月22日 Designed up to onethird longer, it exerts greater pressures in the upper portion of the crushing chamber, distributes crushing action more evenly The result is a gradual reduction of ore to the choking point, and increased capacity! Metal is concentrated at points that make for the most effective jaw designHow does a Rock Crusher Work Jaw Crusher 911

Roll Crusher an overview ScienceDirect Topics

They have a higher capacity than comparable singleroll crushers For example, a tworoll crusher with 24inchlong (61 cm) rolls crushing to ¾ inch (2 cm) has a capacity of 75 tons/h (68 metric tons/h), which is approximately 25 times the capacity of a singleroll crusher with the same roll width and topsize setting2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS2023年1月9日 To calculate the production capacity, you need to multiply the volume of the crusher by the density of the material and the desired output size For example, if the density of the material is how to calculate stone crusher production LinkedIn

Best Ice Crusher Machines For 2023 Refrigerator Planet

Next in our list is the Waring Pro IC70 ice crusher If you are looking for an ice crusher with high capacity and faster work speed, then this ice crusher is made for you With a capacity to crush up to 30 pounds of ice in one go, you can use this ice crusher for commercial purposes This means it can acquire up to 12Rule 1: Always use a jaw crusher if you can due to lower costs Rule 2: For low capacity applications, use jaw crusher and hydraulic hammer for oversize Rule 3: For high capacities, use jaw crusher with big intake openings Rule 4: For very high capacities, use gyratory crusherAMIT 135: Lesson 5 Crushing – Mining Mill Operator Training