Ore Mill Calculation Working Process Of Crushers

2019-05-10T10:05:29+00:00

Advanced comminution modelling: Part 1 – Crushers

2020年12月1日 Particle scale modelling of comminution processes can provide significant insight into the flow of particles, their breakage, the effect of slurry, wear and energy utilisation within these machines Comminution performance also requires changes and 2021年12月15日 The crushers, transportation system and ore processing is monitored and controlled through the ABB 800XA Distributed Control System Figure 1 shows the Crusher to Mill Transportation Time Calculation—The Aitik 2022年1月25日 Layout of the ore transportation system between the crushers and the primary mills Minerals 2022 , 12 , 147 7 of 17 The stockpiles are loaded one at a time, with a mobile conveyor belt used to (PDF) Crusher to Mill Transportation Time

Comminution Circuits for Gold Ore Processing ScienceDirect

2016年1月1日 Introduction For the vast majority of ounces of gold produced, comminution costs in the form of power, grinding media, and liners represent the single largest cost The review of ore crushing and grinding processes at the miningandprocessing enterprise is presented An alternative to the standard technology of crushing ore in cone crushers Reengineering of the ore preparation production The designs of autogenous and semiautogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving Mineral Processing Design and Operations ScienceDirect

Crusher an overview ScienceDirect Topics

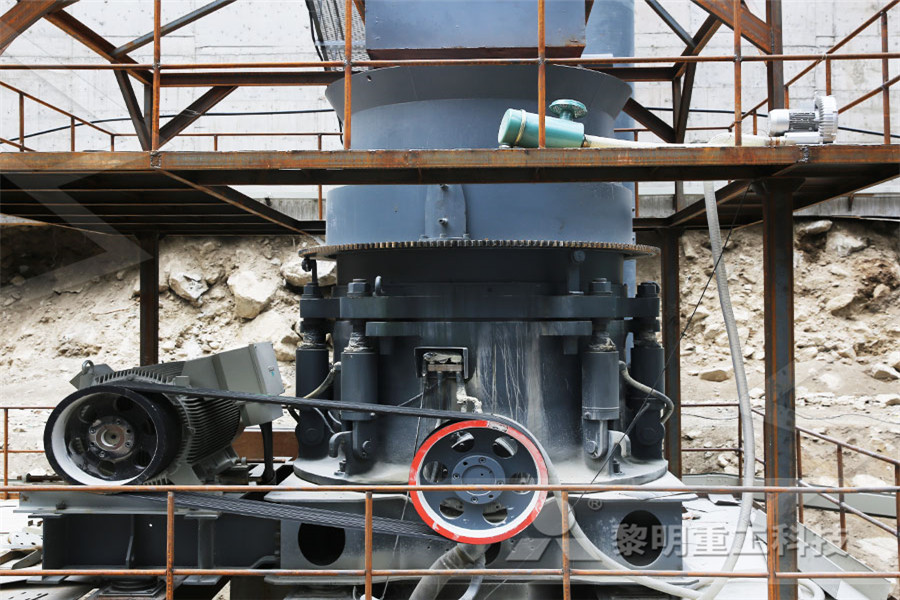

Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers 13311 Primary The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated that mechanical size reduction of Size Reduction of Solids Crushing and Grinding The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 AMIT 135: Lesson 5 Crushing – Mining Mill

Rock Crushing Process in Mining 911 Metallurgist

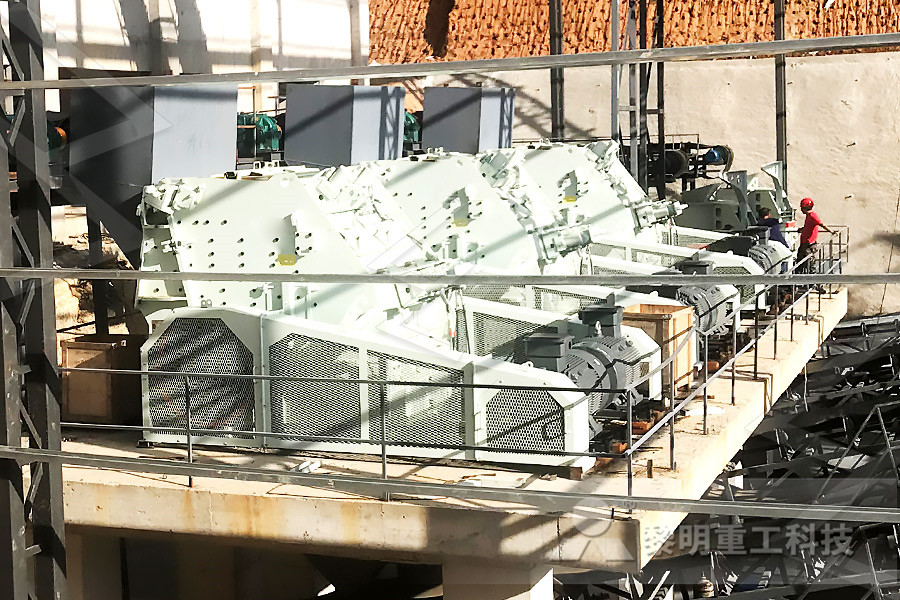

2015年7月18日 Reciprocatingpressure rock crushers include jaw, gyratory, cone, and gyrasphere crushers; continuouspressure rock crushers are typified by rolls, singleroll crushers, and the socalled roller 2017年4月1日 Double roll crushers (DRC) have the highest throughputs among primary crushers 2015) and a tendency towards smaller head grades in ore deposits (Schodde, 2010, Mills, 2015) require technologies capable to efficiently process high throughputs provides valuable information on the behaviour of an ore in the comminution process Dynamics in double roll crushers ScienceDirectGyratory crushers Run of mine material is transferred into a gyratory crusher’s upperlevel hopper The walls of the gyratory crusher’s hopper are lined with “Vshaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone The ore is discharged through the smaller bottom output hole of the coneTypes of Crushers: What You Need to Know Machinery

Crushing in Mineral Processing 911 Metallurgist

2015年12月26日 Crushers for large giant process plants >2,000 to 200,000 TPD using semiautogenous mills only require primary crushing and are selected as well as designed based on: Expected Throughput; F80 Top Feed size distributions; Desired P80 Product size distributions; Feeding method; Ore work index; Ore bulk density; Ore abrasion index 2019年12月23日 The actual capacity was obtained to be 301 kg/h after the performance evaluation of the machine, and it has a 98 % material recovery rate and 7525 % machine efficiency The machine has a (PDF) DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER Gyratory crushers are principally used in surfacecrushing plants The gyratory crusher (Figure 65) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeveThe spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within Crushing Chamber an overview ScienceDirect Topics

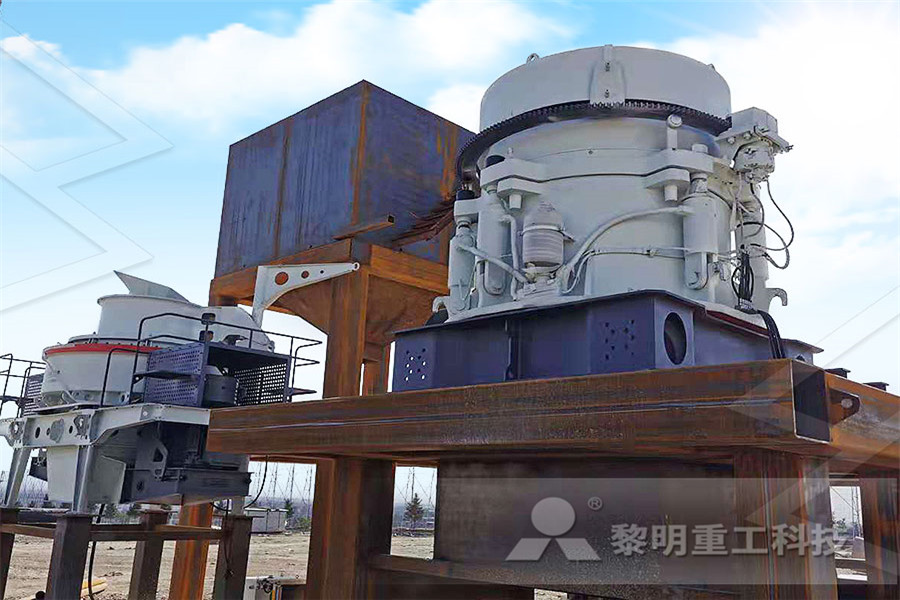

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame, and tramp release mechanism (mechanically or hydraulically actuated) Cone Crusher Components Top Shell Spider Cap Assembly The feed is fed by conveyors to a feed 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics2019年6月28日 For crushers of the first category apply force via pressure, the crushers of the second category apply force via impact In underground mine operations, size reduction is necessary to facilitate the transport of the material to the mill Resizing of material often is the first step in the concentration process of the ore (de la Vergne, 2003)Crushers QueensMineDesignWiki

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日 31 Introduction to Crushing and Grinding of Bauxite The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process2016年1月1日 M = mass of mill ore charge (45 litres) This equation estimates the pinion energy to grind from a feed size, in the full size mill, of 80% passing 152 mm to a ball mill transfer size of 80% passing 17 mm A change in transfer size can be accommodated between 04 and 35 mm by an adjustment using the Bond ball mill work indexSize Reduction and Energy Requirement ScienceDirectSingletoggle jaw crushers are used at the beginning of this process [7] and are among the main machines for crushing Jaw crushers are widely used in many different industries to crush brittle materials with various strength Usually, jaw crushers are put at the beginning of the technological lines of oredressing and sample cuttingRIVLQJOH WRJJOHMDZ FUXVKHU

Crushing Plant Design and Layout Considerations 911

2016年2月24日 As it turned out, designers are now adding secondary or pebble crushers to SAG circuits, on both greenfield and retrofit projects, to increase feed rate to the SAG mill In other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipment2021年8月15日 The choke level is a function of the liner design, eccentric speed, stroke and CSS It has been reported that cone crushers work best when choke fed (Bearman and Briggs, 1998, Jacobson et al, 2010, Santos et al, 2020) and that operating under these conditions extends the durability of both the liners and the equipment 264A review of modeling and control strategies for cone crushers 2019年8月24日 from the ore The process is required to reduce rocks and lumps to smaller pieces Rollers or jaw crushers are employed in this situation The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in relative motion against the other which is stationary while theDesign and Construction of Rock Crushing Machine from

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日 Relatively few models describing the size reduction process occurring in cone crushers have been presented Bond’s model [3], Third Theory of Comminution, presented in the early fiftiesThe designs of autogenous and semiautogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are describedMineral Processing Design and Operations ScienceDirect30413 Crushing rolls Smoothroll crushers: Two heavy smoothfaced metal rolls rotating on parallel horizontal axes are the working elements of the smoothroll crusher illustrated in Fig 304The rolls rotate toward each other at the same speed Feed materials are caught between the rolls and broken in compression and then drop out belowSize Reduction1: Grinding – Unit Operations in Food

A Detailed Overview of Cone Crushers and What You Need

2020年6月3日 Plus, cone crushers can be controlled remotely, helping to reduce work site dangers in the process Cone Crusher vs Jaw Crusher: Key Differences While companies use both machines for crushing raw materials, several vital differences may make one type of crusher better than the other for your application How They Work