Steel Crusher Ball Production Process

2019-01-25T03:01:48+00:00

High Quality Precision Ball Steel Balls

2017年4月5日 Watch the stepbystep precision steel balls manufacturing process by one of Hartford Technologies' facilities in China High Quality Precision Ball Steel Balls Manufacturing: A Process Overview Tel: 860 A working cone crusher (Fig 1313) can perform as a tertiary crusher when installed in a close circuit between secondary crusher and ball mill to crush any overflow material of Crusher an overview ScienceDirect Topics2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial (PDF) Grinding in Ball Mills: Modeling and Process

How are bearing balls made? GlobalSpec

2019年7月31日 The answer is a multistep process that converts a slug of unhardened steel to a hardened, ground and polished round ball Bearing ball manufacturing process Source: Miniature Ball Industries The slug China Steel Ball Crusher manufacturers Select 2023 high quality Steel Ball Crusher products in best price from certified Chinese Steel Factory, Steel Custom suppliers, China Steel Ball Crusher, Steel Ball Crusher Manufacturers, 2020年10月29日 Steps in the Precision Ball Manufacturing Process Raw materials are inspected Cold heading machine cuts off proper length of the wire material, then forms the cylindrical shape into a roughly spherical The Precision Ball Manufacturing Process

Crushing Circuit an overview ScienceDirect Topics

Flow sheet of typical iron ore crushing and grinding circuit Jaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones This is generally 2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, Ball Mills 911 Metallurgist2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation It consists of one or more rotating cylinders partially filled with grinding balls (made (PDF) Grinding in Ball Mills: Modeling and Process

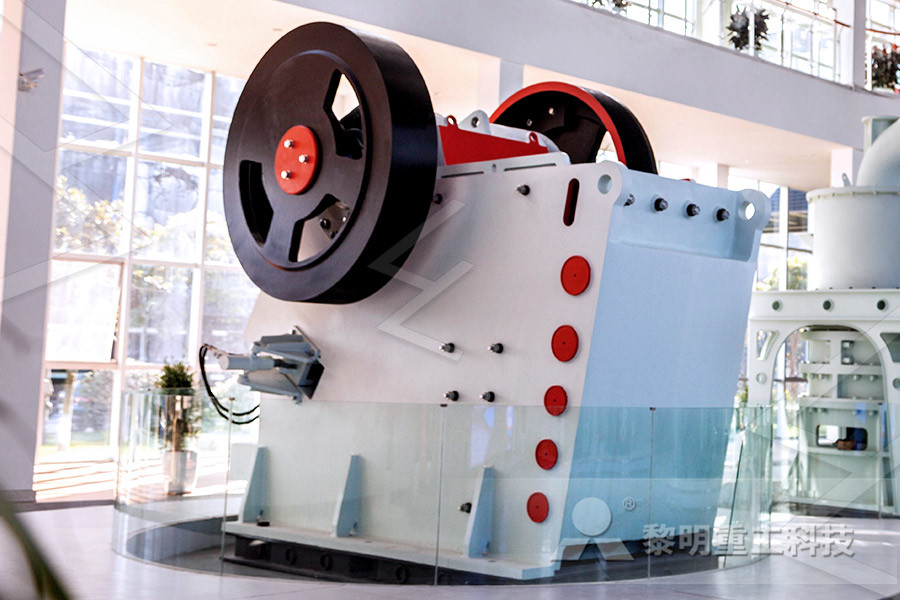

Jaw Crusher an overview ScienceDirect Topics

Rose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws Therefore, dry particles wedged between level A and level B (Figure 44) would leave the crusher at the next reverse movement of the jawProduct Description Ball mill balls are a type of ball used in ball mills, usually made of highhardness materials such as steel, ceramics, hard alloys, etc Ball mill steel balls is an important part of the ball mill, its Ball Mill Balls Manufacturing Of High Quality Ball Impact Crusher The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force and crack is avoided Compared with hammer crusher, the impact crusher is able to fully utilize the highspeed impact energy of entire rotorImpact Crusher an overview ScienceDirect Topics

Manufacturing process Lafarge

2 天之前 Step 2: Crushing, stacking, and reclaiming of raw materials The limestone is crushed in the first crusher called a jaw crusher and then fed into the second crusher called an impact crusher with mixing of clays to reduce particle size below 50mm The discharged raw mix (limestone 70percnt;, clays 30percnt;) is fed onto a belt conveyor and The crusher in closed circuit is then used to reduce the size of the critical size material and return it to the mill As the pebble ports also allow steel balls to exit, a steel removal system (such as a guard magnet, Chapters 2 and 13 Chapter 2 Chapter 13) must be installed to prevent them from entering the crusher (Because of this Grinding Circuit an overview ScienceDirect Topics2023年10月5日 There are several types of industrial crushers available to industrial buyers These types include: Cone or gyratory crushers insert feed via a coneshape bowl and crush it with a spinning or gyrating head HPGR (high pressure grinding rollers), roll/roller crushers, or mineral sizers use two large rollers or a roller and a flat surfaceCrushers Selection Guide: Types, Features, Applications

Crushing and Grinding Process JXSC Machine

2019年10月8日 The ore size reduction process involves two steps: crushing and grinding The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size meet the selection requirements Grinding is a highefficiency and lowefficiency operation The power consumption of crushing operations 2022年10月12日 Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel balls or ceramic are used in the collision container The ball milling process is prepared by rod mill, sag mill, jaw crusher, cone crusher, and other single or multistage crushingTypes of Crushing Equipment models Constro FacilitatorCrushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before What Is The Crushing Process MEKA

(PDF) Design and Performance Evaluation of a Stone Crusher

2021年10月7日 The machine was fabricated using locally available materials The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a throughput efficiency of 754 % The 8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect TopicsCement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be Cement Extraction, Processing, Manufacturing Britannica

Ball Mills 911 Metallurgist

2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume2018年3月8日 This process is necessary to facilitate the yeasts’ multiplication and also to conduct traditional macerations before pressing Field of application The mill consists of a slowly rotating, horizontal steel cylinder, half filled with steel balls (25 – 15 cm in diameter) The final particle size depends on the speed of rotation and on Grinding, crushing Safe Food Factory2021年2月17日 PELLETING The transformation of a soft, often dusty feed into a hard pellet is accomplished by compression, extrusion, and adhesion The general process involves passing a feed mixture through a conditioning chamber where 4 to 6 percent water (usually as steam) may be addedChapter 18 Feed Milling Processes Food and Agriculture

How ball bearings are manufactured GlobalSpec

2017年3月28日 The answer is a multistep manufacturing process involving machining, heat treating, grinding, honing, lapping and assembly Although there may be variations, the following process applies to the vast majority of standard ball bearings produced today Ball bearings are comprised of two bearing rings (or races), balls and (depending on the type The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame, and tramp release mechanism (mechanically or hydraulically actuated) The feed is fed by conveyors to a feed bin above the vertically mounted cone crusherCone Crushers (Parts of a Cone Crusher) Explained saVRee