Crusher Manufacturer Process Meaning

2021-03-15T22:03:27+00:00

How it Works: Crushers, Grinding Mills and

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such Crusher Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages namely by (a) primary, (b) secondary and (c) tertiary crusher From: Crusher an overview ScienceDirect Topics2022年4月20日 manufacturing stage involved the raw material selection , product manufacturing process, and several parts or components The primary material used for SELECTION OF CRUSHER DESIGN CONCEPTS AS A

MODELLING, SIMULATION AND OPTIMISATION OF A

2017年8月23日 DEFINITION OF TERMS The following definitions and terms have been used in this research: Choke feeding A feeding regime to the crusher that keeps the 2023年10月5日 Industrial crushers reduce large rocks, ore, or waste materials to smaller sizes They are the first level of size reducer; further granularization occurs in grinding mills or pulverizers Crushing devices Crushers Selection Guide: Types, Features, The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness Impact Crusher an overview ScienceDirect Topics

Crusher an overview ScienceDirect Topics

View chapter Mechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to The results of the modelling are presented for a baseline case of one industrialscale jaw crusher and compared to manufacturer data Future work will include validation and DEM simulations ViewGeneral flow chart belonging to the Bornova Specifically, blasted limestone is assumed to undergo primary grinding to reduce the mean particle diameter from 40 cm to 102 cm and secondary grinding to further reduce the diameter to 191 cm General flow chart belonging to the Bornova

What Is A Jaw Crusher MEKA

1) Obtaining the size or surface area required for the use of the ore or material 2) Allowing ease of transportation and storage 3) Separating the different minerals contained within the ore and to release them from one jaw crusher BR380JG3 mobile Capacity: 50 t/h 240 t/h Motor power: 159 kW Opening height: 1,065 mm Ecofriendly performance moving to a new stage The operating weight of the BR380JG3 ranges from 33,500 to 35,310 kg, with a Crusher, Crushing plant All industrial manufacturers2021年2月5日 The crushed stone crushing process was investigated in a laboratory centrifugal vertical impact crusher, consisting of the following parts (Fig 1): feed pipe; housing cover; accelerator; acceleration ribs; armor; electric motor; Vbelt transmission Fig 1 Laboratory centrifugal vertical impact crusher: 1 is supply nozzle; 2 is housing cover; 3 isExperimental study of crushing process of the crushed

Gypsum Mining Processing Equipment Flow Chart Cases

1 天前 Gypsum is a mineral found in crystal as well as masses called gypsum rock It is a very soft mineral and it can form very pretty, and sometimes extremely large colored crystals Massive gypsum rock forms within layers of sedimentary rock, typically found in thick beds or layers It forms in lagoons where ocean waters high in calcium and sulfate 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect TopicsSecondary crusher process the primary crusher material that already crushed at material size reduced and tertiary crusher which reduces the material size further The manufacturer gets the desired size That can be further supply to users Operational consideration means you might have constraint in operation like location Location might Should know all about Stone Crusher Plant Machine Thug

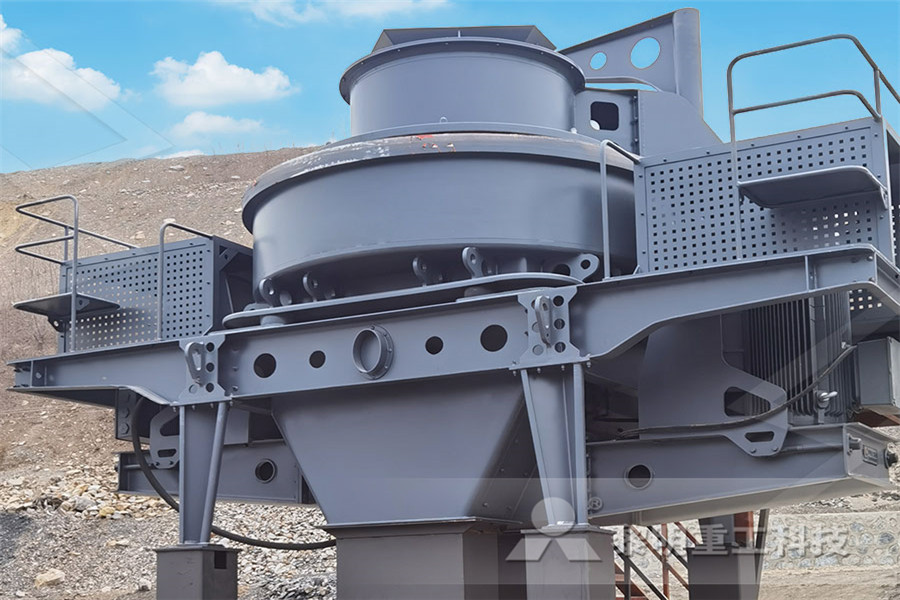

What is msand (Manufacture sand)? Manufacture Process,

The sand must be of proper gradation ( it should have particles from 150 microns to 475 mm proper proportion) Manufacture of the sand process involves three stages, crushing of stones into aggregates by VSI, then fed to Rotopactor to crush aggregates into sand to required grain size Screening is done to eliminate dust particles and Washing 2017年4月19日 The crusher manufacturer usually develops a pattern of sizes that determine the relation of feed opening to largemantle diameter such as 4245, 5474 in, etc with the first number designating feed opening or gape and the last number the mantle diameter Theseelements establish the basic design2 GYRATORY CRUSHERS 911 Metallurgist2021年2月27日 purpose crusher to save crushing energy with less grain losses, is the main aim of this study The components of the designed crushing machine are a hopper, crushing chamber, shaft, hammers, screen, bearings, discharge outlet and a 2HP electric motor Keywords: Crushing, size reduction, Food Grains, Husk Removal, Crushing loss, Design Design of MultiPurpose Crushing Machine for

What Is The Crushing Process MEKA

Crushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before 2021年6月24日 mum production capacity by adjusting process parameters online Original wear and spare parts – using original wear parts is the key to a successful crushing process The design of our certifi ed wear parts starts with CAD simulations of the crusher cavity, which is the heart of the crushing process By computer based planning andCrushing and Screening Handbook AusIMMPropel Industries is synonymous with advanced engineering, costeffectiveness, innovative thinking and custommade solutions We are fast emerging as a most soughtafter brand in the construction and mining India’s Fastest Growing Crushing Equipment

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

2020年4月14日 Manufacturer ABB Type Squirrel cage Induction Motor IE3 (IS 12615:2011) Rated power 55 kW 110 kW 185 kW 220 kW 2 x 185 kW 2 x 250 kW Frequency 50/60 Hz Crusher support frame with antivibration dampers and transportation legs Motor Mounting Bracket with hydraulic (belt tensioning) adjustment2020年7月1日 Rotating drums are often used as washing stations Water is sprayed into the drum and product rotates within the drum, rubbing against itself to remove dirt After washing, the sugar cane or sugar beets are conveyed into the factory using screws or belts The sugar cane is crushed using swinghammer shredders or heavily grooved crusher How Sugar Is Processed IFT2021年2月9日 Grizzly bars on a Vibrating Grizzly Feeder allow fine material to pass through ahead of the crusher Vibrating Pan Feeders Vibrating Pan Feeders are generally used to feed primary crushers in aggregate, mining and recycling applications, but they can also be used to feed grizzly feeders for removing material ahead of a crusherMcLanahan Types of Feeders and Their Applications

Gold Ore Crushing Process and Gold Crusher china

2023年1月19日 Gold ore production process includes crushing, grinding, beneficiation three processes Currently,the gold ore processing methods are as follows: First of all, send the large gold ore to jaw crusher evenly and continuously for primary crushing by vibrating feeder And then, transport the crushed gold ore to cone crusher for secondary crushing2020年9月16日 A jaw crusher is a type of crusher comprised of two jaw plates One is a fixed jaw plate that is vertically fixed on the antetheca of the body, and another is a moving jaw plate, forming a Five Types of Crusher in the Mineral Processing LinkedInStone crushing plant consists of vibrating feeder, jaw crusher, cone crusher, impact crusher, vibrating screen, belt conveyor and electric control panel etc Its designed throughput generally is 50600 t/h It can be adopted to almost all types of materials from stone production to various ores crushing Start a Business in Potential Countries How to Start the Business of Stone Crushing Entrepreneur

A review of modeling and control strategies for cone crushers

2021年8月15日 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017)The maximum distance between the mantle and concave, on the other