Primary Crushing Of Copper Ore

2021-04-12T09:04:22+00:00

Current Status of CopperOre Processing: A Review

2021年9月8日 Primary crushing is commonly carried out as close as possible to a mine or a quarry The crushed ore is transported mainly by a belt conveyor system and, more and more rarely, by truck to the pro cessing plant The competing option of autogenous and 1 天前 Most ores are then sent through a primary crusher, which is typically located very close to or sometimes in the pit This primary crusher Copper Mining and Processing: Processing Copper Overview Mark E Schlesinger, Gerardo RF Alvear Flores, in Extractive Metallurgy of Copper (Sixth Edition), 2022 131 Concentration by froth flotation Copper ores being Copper Ore an overview ScienceDirect Topics

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 Ore, Copper Ore, Zinc Ore and Manganese Ore 41 The art of crushing: plants are used for primary crushing of bulk materials The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of Primary Crusher an overview ScienceDirect Topics2019年1月15日 Abstract In this study, high voltage pulse breakage was used to study the breakage process of copper ore The particle size, shape coefficient and preferential Preferential sequence crushing of copper ore based upon

Particle damage and exposure analysis in HPGR crushing of

2011年10月1日 In the present research, copper ores (copper oxide ore and copper sulfide ore) were crushed by a jaw crusher and by HPGR and the products were evaluated for In some cases, primary crushing takes place underground; in others, a ramp and trucks carry ore to the surface Extraction and refining The extraction of copper from ore is normally carried out in three major stepsCopper processing Ores, Refining, Smelting2011年10月1日 Copper ores (copper oxide ore and copper sulfide ore) were crushed by a jaw crusher and by HPGR Crushed and sized products were evaluated for particle Particle damage and exposure analysis in HPGR crushing of

Minerals Free FullText PreProcessing to

2022年6月6日 The Carajás IOCG deposits show primary and secondary copper sulphides, together with native and oxidized copper minerals, in combination with gold and magnetite Cristalino is one of those IOCG 2015年9月10日 123 Primary Copper Smelting 1231 General1 Copper ore is produced in 13 states In 1989, Arizona produced 60 percent of the total Crushing and grinding systems used in ore, flux, and slag processing also contribute to fugitive dust problems Control of SO2 from smelters is commonly performed in a sulfuric acid plant Use of a123 Primary Copper Smelting US EPA2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) minution and classification technologies of iron ore

Copper Processing Multotec

There could be a primary, secondary and even a tertiary flotation circuit which are responsible for recovering as much of the copper mineral as possible Following mining, transporting, and crushing to the required size, the crushed ore is further processed through a mill and then secondary milling and classification Water is added into 2020年2月3日 For copper mining, fuel consumption increased by 130% and electricity consumption increased by 32% per unit of mined copper in Chile from 2001 to 2017, largely due to decreasing ore gradeTransparency on greenhouse gas emissions from mining to enable Nature2022年6月6日 The Carajás IOCG deposits show primary and secondary copper sulphides, together with native and oxidized copper minerals, in combination with gold and magnetite Cristalino is one of those IOCG deposits with reserves of 200 Mt @ 071% Cu and 03 g/t Au, together with 25 Mt of highgrade hematite iron ore occurring om top of the copper Minerals Free FullText PreProcessing to Increase the

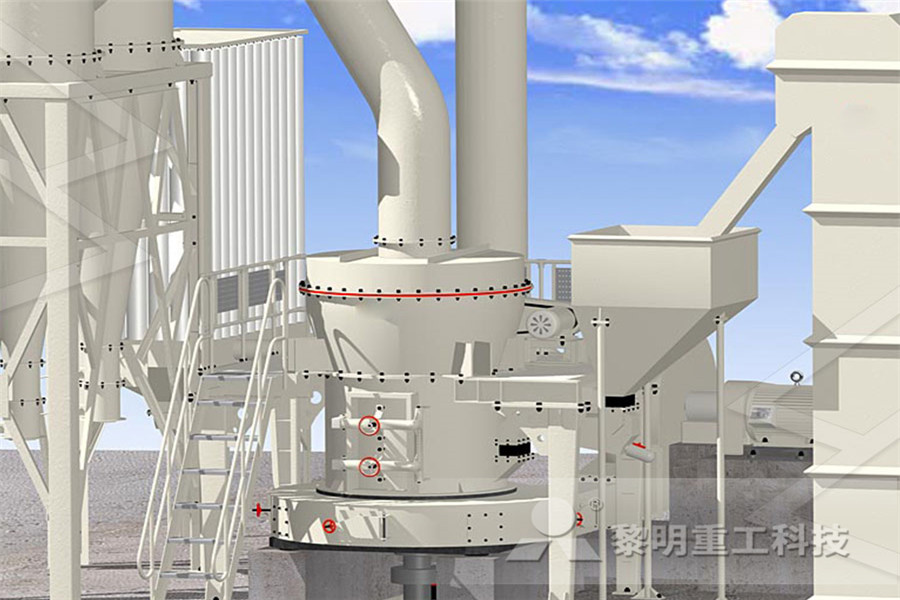

Crushing and grinding process of copper ore Crusher Plant

2022年6月6日 The large pieces of copper ore are evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for coarse crushing Jaw crusher is mainly used for medium particle size crushing of ore and bulk materials, and can crush materials with compressive strength up to 320MpaIt can crush materials with a compressive strength of up to 320Mpa, divided into two types: coarse crushing and fine crushing Eastman has PE and PEX series jaw crushers with complete product specifications Its feed size is 125mm~1020mm, and the single machine output is as high as 600TPH It is an ideal choice for primary crushing equipmentCopper Ore Processing Solution Eastman Rock Crusher2023年2月15日 Jaw Crusher: This type of crusher is used for primary crushing of copper ore It is designed to handle large rocks and produce a consistent size of crushed material Jaw crushers are typically What type of crushing equipment should copper mine

Current Status of CopperOre Processing: A Review

2021年9月8日 Primary crushing is commonly carried MINERAL PROCESSING OF NONFERROUS METALS 376 porphyry copper ore per year (at a grade of 04% copper), applies the bulkdifferential flowsheet and produces copper and molybdenum concentrates The flotation feed is the tertiary grinding overflow of 80%2015年1月1日 On the 1045 mlevel main haulage, 7 × 500 t capacity ore trains, controlled remotely from the surface, collect ore from 10 groups of ore passes and deliver it on to one of four crushing stations where it is crushed to − 100 mm before being hoisted to the surface (Chadwick, 2008) After primary crushing, sampling using a Morgårdshammer Iron ore extraction techniques ScienceDirect2023年4月23日 Copper (Cu) ore is a naturally occurring mineral deposit that contains copper in varying concentrations It is an important industrial metal that has been used by human civilizations for thousands of years due to its excellent electrical and thermal conductivity, high ductility, and resistance to corrosion Copper is widely used in various Copper (Cu) Ore Minerals, Occurrence » Geology Science

Copper Ore Crushing, Grinding Flotation 911 Metallurgist

2017年5月21日 Grinding and Flotation Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the opencircuit 2600mm x 3960mm (8’6 x 13’0) Hardinge rod mill at an average feed rate of 2,106 STPD or 8775 STRH Rod mill discharge at a nominal size of minus 16 mesh and a pulp density of 75 percent solids combines with ball mill discharge 2023年4月25日 11 Coppernickel sulfide ore crushing stage Adopt a twostage closedcircuit crushing process ① Use a jaw crusher for primary crushing ② Use a cone crusher for fine crushing ③ Use a vibrating feeder to screen out the products whose size meets the grinding requirements, while the oversized ones are returned to the cone crusher2 Types of Nickel Ore: Processing Methods and Equipment2017年3月4日 Ore, Copper Ore, Zinc Ore and Manganese Ore 41 The art of crushing: plants are used for primary crushing of bulk materials mainly in ore mines and in the n atural rock industry(PDF) SIZE REDUCTION BY CRUSHING METHODS

123 Primary Copper Smelting US EPA

2015年9月10日 123 Primary Copper Smelting 1231 General1 Copper ore is produced in 13 states In 1989, Arizona produced 60 percent of the total Crushing and grinding systems used in ore, flux, and slag processing also contribute to fugitive dust problems Control of SO2 from smelters is commonly performed in a sulfuric acid plant Use of a2020年10月1日 1 Introduction The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]]In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues Simulation and optimization of gyratory crusher2020年6月28日 According to the Warren Centre, METS can be key players for finding ways to reduce both costs and emissions through innovation, a path that should also include government and research institutions Pathways towards zeroemission copper mines

Grasberg Open Pit Copper Mine, Tembagapura, Irian Mining

2020年6月24日 The ore undergoes primary crushing at the mine, before being delivered by ore passes to the mill complex for further crushing, grinding and flotation Grasberg’s milling and concentrating complex is the largest in the world, with four crushers and two giant semiautogenous grinding (SAG) units processing a daily average of 240,000t of ore2022年7月12日 Chalcopyrite is the main mineral source of copper ore for extracting and producing copper However, with the continuous mining of copper ore, the grade of chalcopyrite decreases year by year and its composition becomes more and more complex The traditional pyrometallurgical extraction process has been unable to make efficient A Review on the Research of Hydrometallurgical Leaching of Contribute to zhosuren/es development by creating an account on GitHubes/primary crushing of cuppermd at main zhosuren/es