Crushing Sieving Mm

2021-05-09T16:05:51+00:00

Wet sieving versus dry crushing: Soil

2020年6月18日 It seems plausible that both wet sieving and dry crushing yield different results for the OC distribution of the different aggregate size fractions During wet sieving (especially with sonication), large primary 2007年9月13日 Crushing and Sieving When a sample arrives it is first crushed and sieved This is to obtain the correct grain size for the rest of the separation process The ideal Crushing and Sieving Purdue University2019年9月26日 Crushing: particles the division of the original particle into some rough (work in the ‘mm’range) Milling: the division of the rough particles and gain fine powders Crushing, Grinding, Milling, Sieving PTE

Metal recovery from incineration bottom ash: Stateofthe

2020年7月5日 Iron scrap and stainless steel are removed by magnetic separation from the particles larger than 40 mm Particles smaller than 40 mm are led into the wet drum sieve 2019年1月1日 In laboratory, samples were screened in 254 and 48 mm sieves Fractions below 48 mm and between 48 and 254 mm were weighted for mass balance and Concrete aggregates properties crushed by jaw and impact secondary crushingOnce the sample has been crushed, it can be sieved to obtain the correct grain sizes After sieving the sample is bagged according to grain size, usually resulting in three classifications; >5mm, 25mm5mm, and Crushing and Sieving: Purdue Rare Isotope

The influence of crushing processes and mineralogy of aggregates

2021年5月17日 Crushing processes Shape properties Degradation resistance 1 Introduction Mineral aggregates are widely used as materials incorporated into different 2023年2月1日 Crushing Sieving Mechanical treatment 1 Introduction As nonrenewable fossil fuel reserves deplete rapidly, renewable and greener energy alternatives have A facile crushandsieve treatment for recycling endoflife 2010年7月1日 The results indicate that the crush ratio below the 50 mm sieving plate increases linearly with an increase in impact velocity and decays exponentially with an Directimpact of sieving coal and gangue ScienceDirect

The difference between sieving and classification China

2021年2月8日 Sieving: Strictly according to the particle size: With even particle size and same average diameter in sibling products: With low working efficiency for fine particle 2022年10月13日 The model used a roller diameter of 250 mm and length of 1620 mm, upper sieve length of 3000 mm and width of 1650 mm; crushing guide roller diameter of 280 mm and length of 1630 mm, lower Agriculture Free FullText Simulation and The RSM results demonstrated that the characterized feeding size (F80, mm) dominates the general size reduction, whereas the feeding quantity (mf, g) is associated with the crushing energy Particle size fractions and related sieve sizes used for the

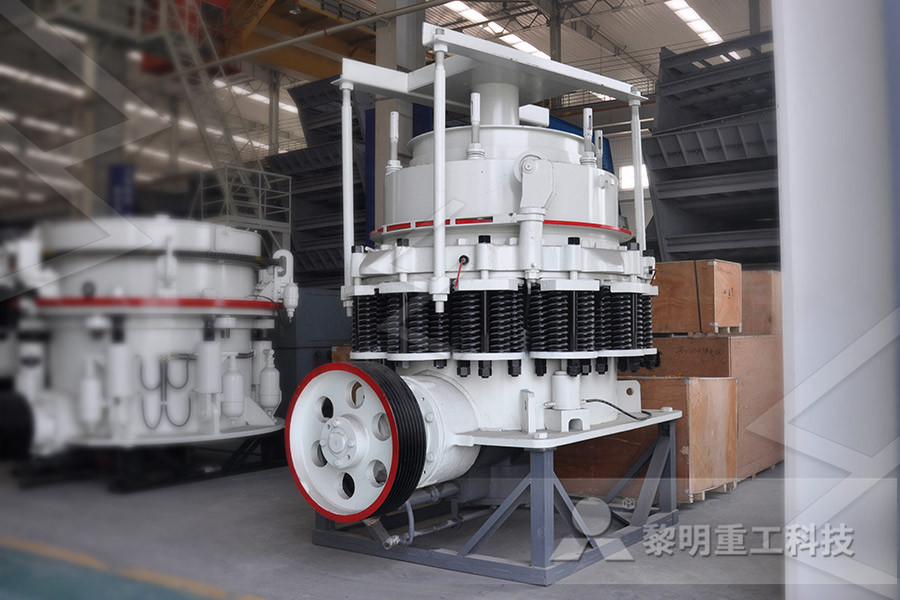

Crushing Chamber an overview ScienceDirect Topics

Gyratory crushers are principally used in surfacecrushing plants The gyratory crusher (Figure 65) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeveThe spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within 2010年7月1日 The results indicate that the crush ratio below the 50 mm sieving plate increases linearly with an increase in impact velocity and decays exponentially with an increase in hardness 1983, 50(6): 249268 [12] Zhang E G Equipment of SievingCrushing and Dewa tering Beijing: China Coal Industry Publishiing House, 1991 (In Directimpact of sieving coal and gangue ScienceDirect2019年10月18日 the aggregate crushing value (ACV) which gives a relative measure of the resistance of an aggregate to crushing under a gradually applied compressive load The method is applicable to aggregates passing a 140 mm test sieve and retained on a 100 mm test sieve For other size fractions, there is another recommended methodMethods for determination of aggregate crushing value

A Guide to Mineral Separation (v 1) Middlebury College

2011年8月26日 Part 2: Crushing, Sieving, and Magnetic Separation Safety Notes: Make sure to always wear eye protection and a dust mask Never stick your head directly above, or close to the top opening Use the paddle to cover the opening of the jaw crusher after you drop a rock fragment into it2013年1月1日 The recovery of flour using the 05 mm and 055 mm sieve apertures is presented in Table 2, Table 3, respectively Results show that further sieving tends to augment the percentage of the flour recovered from the mortar mill and this indicates improper milling of the chips and the nonuniformity of the particles size of the milled Effect of Milling Machines and Sieve Sizes on Cooked Cassava Flour Sieving is a method of using a sieve to distinguish small particles from bigger particles It is used in flour mills or building sites Impurities such as husks and stones are extracted from wheat at flour mill They remove pebbles and stones from sand by sieving To learn more about sieving and other separation techniques download BYJU’S Sieving Definition Process, Sieving Method Of

A combined vacuum crushing and sieving (CVCS) system

2017年7月21日 A VACUUM CRUSHING AND SIEVING SYSTEM 101002/ggge20164 2434 between piston and crushing table determines the approximate maximum grain size of the crushed material and can be set with a resolution of 10 mm The crushing process can be observed through a glass viewport in the front plate of the crusher chamber During Apart from dry sieving to a certain size (typically 8 or 4 mm), the aggregates in the aforementioned studies are usually not treated by dispersion agents before the dry sieving Another approach, which is able to liberate more microaggregates that are trapped within macroaggregates (Six et al, 2000), can be to mechanically crush the Wet sieving versus dry crushing: Soil microaggregates reveal 2018年8月2日 After careful crushing, sieving, and density separation, one pyroxene separate (Px A), three plagioclaserich separates (Plag A, B, and C), and one silicarich separate (SiO 2) were handpickedSilicarich volcanism in the early solar system

Crushing and Sieving: Purdue Rare Isotope

Select two sieves and clean them thoroughly with a brush and a dissecting needle The goal is to eliminate polymineralic grains, so the coarser sieve should have openings somewhat smaller than the average crystal size in 2019年11月7日 Recommended Method for Crushing and Sieving Soils Because soil is defined as having a particle size of less than 2 mm, this sieve size (10 mesh) is recommended for routine soil testing Various soil grinders and crushers are available commercially and are typically large, motorized, mortar and pestles, hammermills, or Soil Sample Preparation and Extraction University of 2023年2月14日 For the present research, dry sieving was performed to determine the black curve with the main sieving machine parameters illustrated in Figure 6 The sieving tower was rotating at 42 RPM around its axis while circling at 180 RPM The amplitude was 40 mm and at each rotation, the sieve hit five rubber stoppers that made it shakeThree indexes to characterise crushing and screening of

A combined vacuum crushing and sieving (CVCS) system

2013年5月6日 [1] This paper presents a novel extraction device for water and noble gases from speleothem samples for noble gas paleotemperature determination The “combined vacuum crushing and sieving (CVCS) system” was designed to reduce the atmospheric noble gas contents from air inclusions in speleothem samples by up to 2 orders of 2022年12月1日 The aggregates were initially separated by either wet sieving or dry sieving before dry crushing Our results indicated that aggregate crushing led on average to +31 % stimulation of carbon mineralization compared with intact aggregates, which represented 065 to 101 % of total SOC Initial aggregate size (mm) Crushing operation Crushed to Drivers of the amount of organic carbon protected inside soil 2022年5月1日 Zircon crystals from these samples were collected by standard techniques including crushing, sieving, panning and magnetic separation followed by hand picking under a binocular microscope All the zircon grains (nearly 200 zircons per sample) were then mounted in an epoxy resin and polished down until the grains were fully exposedZircon mineral chemistry and implications for magmatic

77 Aggregate Crushing Value and 10% Fines Value 771

2002年1月29日 crushes the aggregate to a degree which is dependent on the aggregate’s crushing resistance This degree is assessed by a sieving test on the crushed specimen and is taken as the Aggregate Crushing Value 7714 Sampling The sample used for this test shall be taken in accordance with Chapter 2 7715 Equipment2008年4月15日 sieving 1 to 2 mm aggregates, use a screen with mesh openings of 025 mm (¼ of 1 mm) The screens are placed in the preweighed weigh boats to collect dust that passes through the screen during weighing and for capillary rewetting (Step 3) 3 Samples are capillary rewetted from underneath by adding MilliQ (or double distilled)SOIL AGGREGATE ANALYSIS USDA ARS2019年9月26日 Grinding •Grinding: the mechanical process of reducing particle size of solids, while the specific surface area increases parallel with the reduction of the particle size It is commonly done by mills •Crushing: the division of the original particle into some rough particles (work in the ‘mm’range) •Milling: the division of the rough particles and Crushing, Grinding, Milling, Sieving PTE