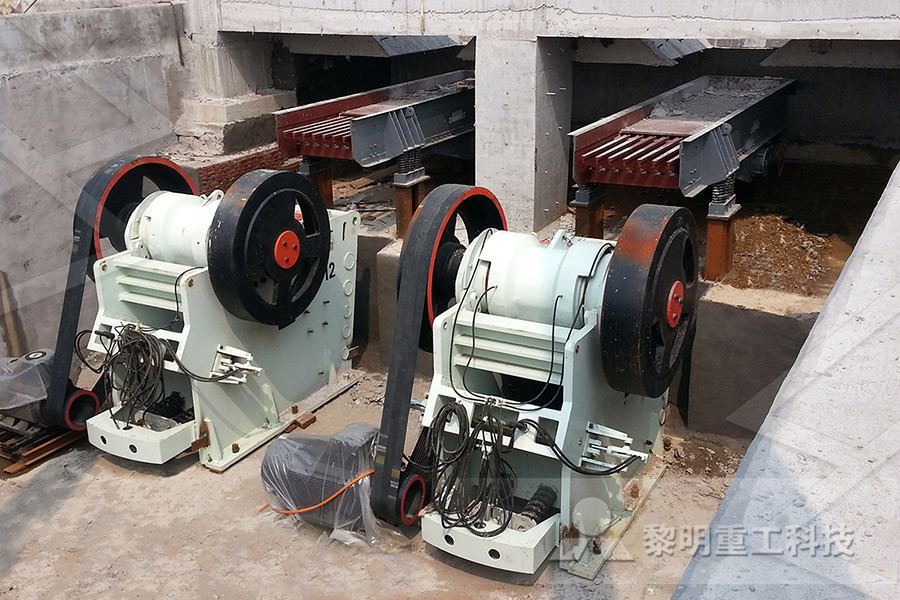

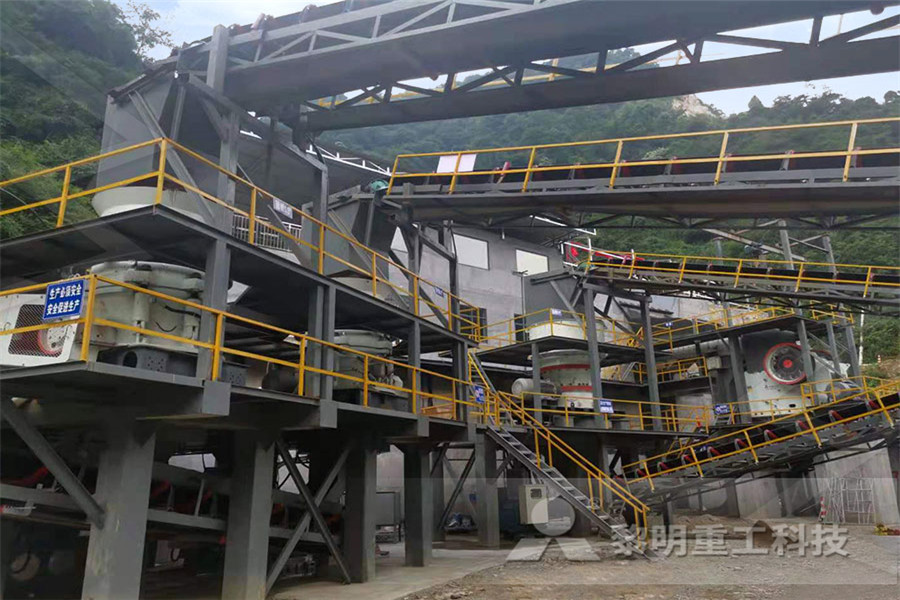

Aggregate Crusher Operated

2020-04-20T15:04:40+00:00

Aggregate Crusher Aggregate Processing Solutions

2023年9月22日 has a full coverage of coarse crushing, intermediate crushing, fine crushing and sandmaking, sandwashing, feeding, sieving, conveying equipment and China Aggregate Crushing Machine manufacturers Select 2023 high quality Aggregate Crushing Machine products in best price from certified Chinese Mining Machine, Mining China Aggregate Crushing Machine, Aggregate Crushing 2021年11月6日 1 Introduction Production of mineral aggregates is realized in processing circuits that use mostly crushing and screening operations However, these relatively Minerals Free FullText Optimization of Aggregate

Site Safety and Safer Aggregate Crushing Operations Agg

2019年9月11日 Before even stepping on site to work with a crusher, employees and/or operators must be trained on all safety procedures for both the site and the crusher For 2018年9月10日 Selecting an appropriate crusher, or indeed any piece of processing equipment, is important in every quarry operation Understanding what each crusher type Understanding the Different Types of Crushers AggNetCrushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in mining Crushers All crusher types for your reduction needs

Crushing 101 – Different types of crushers for

2020年12月17日 All rock crushers can be classified as falling into two main groups Compressive crushers that press the material until it breaks, and impact crushers that use the principle of quick impacts to crush the 2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal Aggregate Production Optimization in a StoneCrushing 2019年1月1日 Given that crushing is fundamental for phase liberation, this paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates Concrete aggregates properties crushed by jaw and

Aggregate Crusher Wash Plant Operator Jobs, Employment

16 Aggregate Crusher Wash Plant Operator jobs available on Indeed Apply to Equipment Operator, Plant Operator, Operator and more!Aggregate Processing Recycling Ltd Tamworth, United Kingdom B77 5EX Phone: +44 1827 Contact Us The McCloskey I4CR is a heavyduty track mounted Crusher with 1050mm (413") diameter x 1125mm (443") wide Impactor, Crawler Tracks, integrated hydraulic folding stockpiling conveyors, Ibeam platSee More DetailsCrusher Aggregate Equipment For Sale 2672 Listings2015年7月1日 After the VSI crusher, the final crushed sand products are usually classified with washing equipment or air classifiers in order to reduce the fines 2 content In secondary and tertiary aggregate crushing stages the most commonly utilised crushing equipment are cone crushers The major advantage of the cone crusher is its ability to limit the Sand production with VSI crushing and air ScienceDirect

Used crushers for sale Mascus UK

Types Of Used Crushers Available At Mascus Find a wide selection of used crushers for sale at Mascus – whether you’re looking for used crushers from Svedala, , Kueken, and more, Mascus is the place to find the perfect used crusher equipment for you Explore our range of second hand crushers for sale with help from our handy 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics2023年10月4日 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types 2 Types of Rock Crushers Quarry Crushing Equipment Kemper

Table 6 Energy consumption values of each crusher per tonne

For the sedimentary rocks (Siltstone) the specific crushing energy is approximately 126 kJ/kg Tosun and Konak (2014) measured power consumption of jaw crusher during crushing of limestone rocks 2018年9月10日 Impact crushers An impact crusher uses mass and velocity to break down feed material First, the feed material is reduced as it enters the crusher and makes contact with the rotating blow bars or hammers in the rotor Secondary breakage then occurs as the material is accelerated into the stationary aprons or breaker platesUnderstanding the Different Types of Crushers AggNet2022年11月21日 Stationary singleshaft impact crusher fed by two apron feeders at Cementos Progreso SA, Guatemala Type PB 200/250 CR Throughput rate 1,100 t/h Mobile impact crusher with hydraulic walking mechanism at Martin Marietta, Texas, USA Type PB 250/300 CR Mobile wheelmounted impact crusher at SPCC Southern Province Cement Industrial Solutions Impact crushers ThyssenKrupp

Concrete aggregates properties crushed by jaw and

2019年1月1日 Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates The proportion of particles finer than 015 mm is around 7–8% weight for both crushing 2023年7月15日 Use of cranes (including manually operated lifting tackle), Lifting and Slinging When hydraulic arms are not available and cranes slung with hooks have proved ineffectual, other methods are necessary When it becomes necessary for a person to enter the crusher to position hooks or slings, the crusher and feeder must be stopped, isolated HSE Quarries Safe operation and use of mobile jaw crushers2022年1月1日 Fig 5 shows the mean elongation of the four coarse aggregate fractions for JC and JJ crushers The test results showed that the particles obtained from JC crusher indicated lesser elongation in comparison with JJ crusher For all the size ranges, American Society for Testing and Materials (ASTM) and Indian Standards (IS) specifies a minimum Effect of crushing mechanism on the shape properties of

Concrete Sustainability Council

2022年10月25日 Aggregate Crusher Plants: Aggregates are generally extracted from a quarry or a pit and subsequently processed Pure aggregate crusher plants do not own their own quarry or gravel pit and their aggregate production consequently depends on (external) raw aggregate supply Some of the relevant environmental impacts of aggregate Red Rhino 7000 Plus Concrete Crusher £60000 Collection in person 34 watching Mobile Stone/Concrete Crusher For Hire Plant Hire/ Groundworks £65000 £290 postage or Best OfferConcrete Crusher for sale eBay2022年11月21日 using a handoperated hydraulic device and shim plates or automatic adjust ment of the crushing gap • Crushers can be used as stationary crushers or they can be integrated into wheelmounted or trackmounted mobile crushing plants • Central lubrication system ensures a reliable lubricant supply From top: Singletoggle jaw crusher Industrial Solutions Jaw crushers ThyssenKrupp

Typical Crushing Plant Process and Procedure for Concrete Aggregate

Content may be subject to copyright Typical Crushing Plant Process and Procedure for Concrete Aggregate 2Technical Properties of Recycled Concrete Aggregates 2pressive Strength: There 76 Problems 71 A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 μmCrushing Plant an overview ScienceDirect Topics2016年2月24日 • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variationsCrushing Plant Design and Layout Considerations 911

Open or Closed Circuit Crushing 911 Metallurgist

2016年2月29日 Closed Circuit ReductionStage Capacities Thus far we have considered opencircuit crushing through the several reductions in a multistage crushing plant Very rarely are we able to turn out a finished product without closing the flowline circuit somewhere along the line Without going into any argument for or against closedcircuit 2016年1月12日 Crusher, operated in closed circuit @ 3mm, producing product at 80 metric TPH Minus 3mm Crushed Glass Glass Recycling Recycle into new glass products, Golf Bunker Sand, Aggregate Sand, Aquarium filtration, Garden Centre weed suppressant, Patio Slab surfacing, Tile Grouting,HSI Crushers 911 Metallurgist