Long Durability Impact Crusher For Stone Crushing

2023-06-03T10:06:31+00:00

Experimental study of crushing process of the crushed

2021年2月5日 laboratory centrifugal vertical impact crusher for studying the process of crushing local gravel to obtain crushed stone with dimensions of 520 mm The main influencing factors for the process are the average size of the incoming raw materials, 2022年5月13日 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [1] In infrastructure industry, these Stone Crushers: A Technical Review on Significant Part of 2021年5月17日 Even so, all tested materials presented angularity of coarse fractions classified as subrounded When it comes to the fine fractions (from 236 mm), the The influence of crushing processes and mineralogy of aggregates

Impact Crusher an overview ScienceDirect Topics

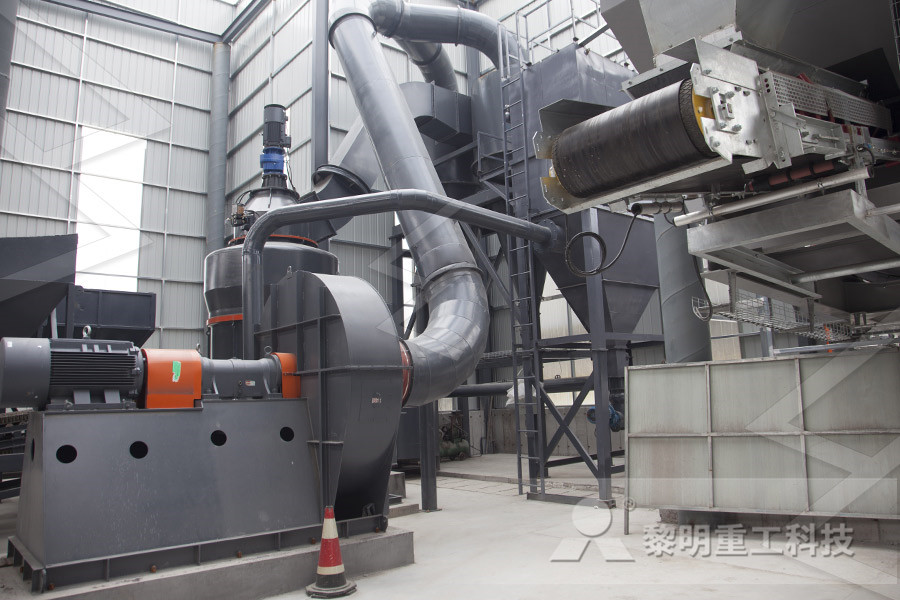

Impact Crusher The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of 2019年3月1日 An impact crusher is rarely used with hard rock materials due to wearing Commonly, an encapsulated sieve is adopted together with every crushing unit apart Dust emission from crushing of hard rock aggregates2022年5月14日 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [ 1 ] In infrastructure industry, Stone Crushers: A Technical Review on Significant Part of

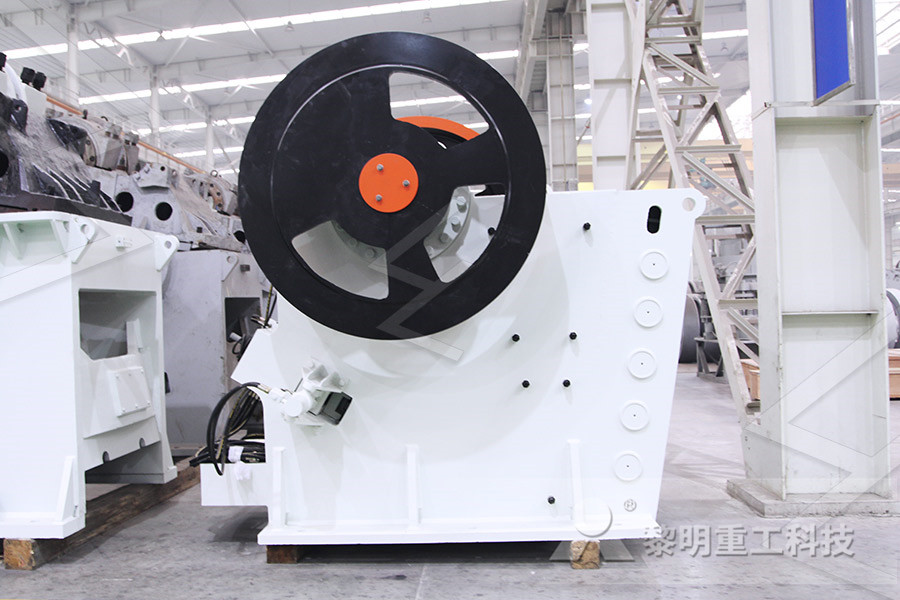

Long Durability Stone Impact Crusher; Impact Stone Crusher

2023年5月3日 Long Durability Stone Impact Crusher; Impact Stone Crusher, Find Details and Price about Mobile Impact Crusher Mini Impact Crusher from Long Durability Stone 2020年6月4日 Metrics Abstract The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of Evaluation of size reduction process for rock aggregates in cone crusher2019年5月30日 摘要: 软硬不均复合地层中地质条件频繁变化,盾构滚刀磨损加剧严重制约施工效率。 为探索复合地层土压平衡盾构机滚刀耐磨蚀改进措施,准确预测复合地层土 复合地层土压平衡盾构滚刀磨损规律及切削距离寿命预测分析

SOCIOECONOMIC AND ENVIRONMENTAL IMPACT OF

2022年7月22日 1 To identify social problems found in stone crushing units of Villupuram district 2 To delineate the economic impact of the industry to the livelihood of the workers 3 To understand the environmental impact on workers due to stone crushing industry 4 To offer suitable suggestions based on the findings of the study 4 Hypothesis of the study2023年2月15日 1 Coarse crushing: Basalt is sent to a jaw crusher through a vibrating feeder for coarse crushing; 2 Secondary crushing: Then the hardrocks are sent to a cone crusher through a belt conveyor for Which Crusher Is Suitable for Your Hard Rock?2019年3月1日 All processes of aggregate production are potential sources of dust emission Dust constitutes a major environmental concern in many quarries, with crushing suggested as the most significant source of it ( Bada et al, 2013; Petavratzi et al, 2005; Sairanen et al, 2018 ) Dust from drilling has been previously examined in two natural Dust emission from crushing of hard rock aggregates

The influence of crushing processes and mineralogy of aggregates

2021年5月17日 The higher Treton impact resistance for aggregate BI results from its lower flatness (2:1) (45% of particles versus 867% of particles for aggregate BQJ) This difference is a function of the crushing process (impact versus jaw crusher) This way, this regression model incorporates both mineralogical and crushingrelated characteristics2023年5月12日 The six bestselling granite crusher machines are jaw crusher, cone crusher, impact crusher, sand making machine, mobile crusher, and portable crusher This article will share with you the pros and cons of these granite crusher machines to help you pick the right one The reason for the popularity of granite rock crushing equipment is the 6 Granite Crushers for Efficient Granite Rock Crushing2019年3月1日 Crushing produces mainly coarse (TSP and PM 10) dust particles which settle near the dust source The mass concentration of coarse particles varied from few tens of μg/m 3 to over 6 × 10 3 μg/m 3 downwind from the crusher The mass concentration of fine particles (PM 25 and PM 1) ranged between ten μg/m 3 and few hundreds of μg/m 3 Dust emission from crushing of hard rock aggregates

Types of Crushers: What You Need to Know Machinery

In 1883 Mr Blake challenged Mr Gates to crush 9 cubic yards of stone in a contest to see which crusher would finish the job faster The Gates crusher completed the task 40 minutes sooner! The Gates’ gyratory crushers were preferred by the mining industry for almost two decades until the turn of the century, circa 1910, when Blake’s jaw The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect Topics2011年3月23日 Stone crushing and associated activities mainly contribute to particulate matter in the surrounding environment The mean minimum and maximum values of SPM at crushing and residential sites were (PDF) Environmental health assessment of stone crushers

Crusher an overview ScienceDirect Topics

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Impact crushers are traditionally classified to two main types: horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each otherCrushers All crusher types for your reduction needs Mechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer Crusher an overview ScienceDirect Topics

(PDF) Research on crushing and recycling of waste concrete

2020年3月21日 mechanical impact caused by crushing, s creening, st rengthening and other processes will a lso produce such fine powder [20] The inner part of regenerated powder is lo ose and its surface is rough2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several Evaluation of size reduction process for rock aggregates in cone crusher2023年10月4日 The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, low abrasion applications No shear or compressive crushing action takes place and every stone is broken by impact forces at its weakest point to provide an exceptionally strong Impact Crushers Parker Plant

what is an impact crusher LinkedIn

2023年4月6日 An impact crusher is a type of crushing machinery that is designed to reduce large rocks and other materials into smaller pieces It is commonly used in the mining, construction, and recycling Stationary crushers screens We are your longterm partner providing safe and sustainable solutions to optimize productivity through proven expertise in stationary crushing screening Our Sandvik crushing and screening equipment is engineered for maximum productivity We offer advanced, proven solutions for any sizereduction and Rock Crushers, Stone Crushers, Screening and Crushing 2021年11月22日 Heavyduty impact crusher brings the power and productivity of a 443in impactor to a compact footprint for maximum maneuverability McCloskey International Ltd May 4, 2021Mobile Crushing Saves Time Money For Construction Pros

Impact Crusher Machines Williams Patent Crusher

The Williams Reversible Nuggetizer® Impact Crusher (US Patent No 3,667,694) is also often used for various types of automotive and metal scrap Contact us today to discuss your application in detail with one of our experienced sales engineers Call (314) 6213348, us at info@williamscrusher or locate an agent near you2019年9月2日 With impact crushing, the stone breaks along its natural cleavage lines, resulting in a more cubical product, which is desirable for many of today’s specifications HSI crushers can be primary or secondary crushers Roll crushers are a compressiontype reduction crusher with a long history of success in a broad range of applications The PQ University Lesson 7: Crushing Secondary Breaking