Ore Impactor For Ore Beneficiation

2022-05-15T02:05:08+00:00

Driving investments in ore beneficiation and scrap upgrading

2021年5月20日 For both materials, other benefits may be obtained such as a decreased phosphorus content due to the ore beneficiation and decreased copper contents due to an improved scrap upgrading From a resource conservation perspective, the iron loss in 2020年2月8日 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making Existing and New Processes for Beneficiation of Indian Iron 2022年6月1日 An estimate on the costs for the necessary ore beneficiation is 25 USD/t pellet concentrate and for a scrap upgrade, it is 12 USD/t scrap(PDF) Driving investments in ore beneficiation and scrap upgrading to

Ore Beneficiation an overview ScienceDirect Topics

Abstract To evaluate an iron ore resource, develop processing routines for iron ore beneficiation, and understand the behavior of the ore during such processing, extensive 2021年11月24日 Beneficiation Strategies for Removal of Silica and Alumina from LowGrade HematiteGoethite Iron Ores V Nunna , S P Suthers , M I Pownceby G J Beneficiation Strategies for Removal of Silica and Alumina 2023年1月1日 This chapter briefly discusses the current scenario of the iron ore resources in India, iron ore mining methodology, beneficiation technique, and the current operating Iron ore beneficiation: an overview ScienceDirect

Iron ore beneficiation: an overview ScienceDirect

2023年1月1日 This chapter briefly discusses the current scenario of the iron ore resources in India, iron ore mining methodology, beneficiation technique, and the current operating 2022年1月1日 This article presents information on the wastes generated and associated during iron ore extraction and beneficiation, and their environmental impacts Further, it A short review on environmental impacts and application of iron ore 2023年3月29日 The ratio of bastnaesite to monazite in the deposit is approximately 3:1, and REEs are recycled from iron ore processing tailings 42, 43 There are three mining areas in the Bayan Obo deposit The Main Ore Body and West Ore Body were mined by Baotou Iron and Steel Group in 1957, and the West Ore Body was exploited in 2004 5 Recent process developments in beneficiation and

224: Beneficiation Chemistry LibreTexts

224: Beneficiation Beneficiation is any process which removes the gangue minerals from ore to produce a higher grade product, and a waste stream Beneficiation may involve physical or chemical processes Often, as in the case of panning for gold, the desired ore or metal is denser than the gangue2023年1月1日 The beneficiation studies of Suresh (1981) illustrate that lowgrade chromite ore of 16%–25% Cr 2 O 3 of Sitampundi area of India, cannot be upgraded by using conventional physical beneficiation techniques like gravity and flotation, due to the intimate association of iron in the lattice of chromite particle However, they have demonstrated Chromite ore beneficiation: prospects and challengesThis study focussed on flowsheet simulation for mineralogicalbased approach to geometallurgy of iron ores Process unit models used were selected based on their applicability at particle level for iron ore beneficiation and flowsheet simulation The feed streams for plant simulation were runofmine feed and forecast feed from ore textural Process simulations in mineralogybased geometallurgy of

Beneficiation of LeadZinc Ores – A Review: Mineral

2021年3月28日 This paper summarizes the classification of ore deposits and different beneficiation techniques that are currently employed for the treatment of leadzinc ore Froth flotation is the most widely used beneficiation technique The selection of a suitable reagent regime in view of varied mineralogy, physical and chemical characteristics of lead Iron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion The bioprocesses are specially suited to treat fines, slimes, and waste tailings 4 Potential applications includeOre Beneficiation an overview ScienceDirect TopicsIn mines and ore handling plants Slurry Pumps are used for dewatering the sump pits In beneficiation plants Slurry Pumps are used in conveying ore slurries from and to various units of beneficiation circuit Thickeners Thickeners are used in Beneficiation Circuits to dewater/ thicken coal/reject slurries for further processing useMINERAL BENEFICIATION McNally Sayaji

Beneficiation an overview ScienceDirect Topics

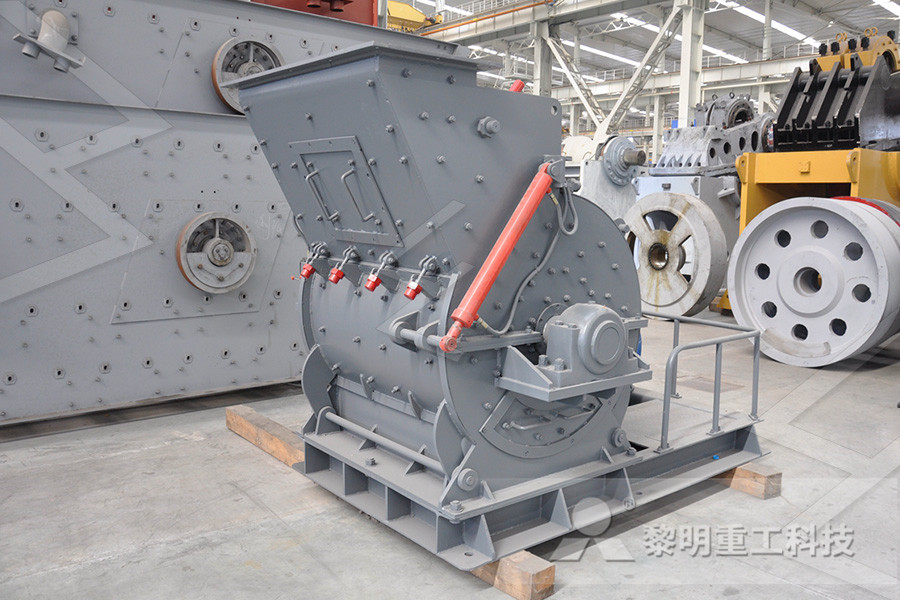

WG Davenport, in Encyclopedia of Materials: Science and Technology, 2001 11 Physical Beneficiation Beneficiation of copper ores is done almost exclusively by selective froth flotation Flotation entails first attaching fine copper mineral particles to bubbles rising through an ore–water pulp and, second, collecting the copper minerals at the top of the Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining application Whether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction With a wide range of equipment that performs mineral and ore crushing, size reduction, beneficiation Ore, Mineral, Slag Crusher Stedman Machine Company2013年11月8日 412 Iron Ore Beneficiation Iron ore occurs naturally in a variety of forms, from sandlike iron fines to solid rock masses Crude ore, or ore mined in the natural state, seldom occurs in a pure state and requires some form of beneficiation Crude ore is commonly mixed with other minerals (gangue), which reduce the iron contentEnergy and Environmental Profile of the US Mining

Quantitative mineralogical characterization of chrome

2017年8月28日 comprises of predominantly powdery and friable ore types, and during mining, considerable quantities of lowgrade ores (Cr2O3: 45wt%) During beneficiation, approximately 50wt% of the 2020年3月26日 The beneficiation circuit includes the comminution circuit, lowintensity magnetic separators (LIMS), highintensity magnetic separators (HIMS), and combined direct and reverse flotation circuit The runofmine ore was subjected to primary and secondary crushing and grinding units to generate 90–95% material finer than 74 μmMineral Processing of Rare Earth Ores SpringerLink2019年12月15日 The importance of ore sorting in improving economics of marginal deposits is increasing, being realized by the mining industry (Lessard et al 2014; Foggiatto et al 2014) At present, majority of automated ore sorters , outside of the diamond industry, are color or conductivity sorters (Bartram and Kowalczyk 2009) This is a significant Beneficiation of Gold and Silver Ores SpringerLink

Comminution and classification technologies of iron ore

2022年1月1日 Ore that is less than 40 mm but greater than 8 mm is conveyed to the lump stockpile Ore that is finer than 8 mm, but greater than 1 mm is conveyed to the fines stockpile Any ore that is finer than 1 mm in size is conveyed to a desanding plant consisting of cyclones, upper current classifiers and two stages of spirals for further 2017年5月1日 Beneficiation of any ore depends not only on the chemistry of the feed material but also on the texture and associated minerals The concept of the paper is to assess the impact of mineralogical and textural effect for ascertaining the possible beneficiation scheme for the goethitic types of ores from different origins 2 Materials Mineralogy and textural impact on beneficiation of goethitic ore2022年1月1日 For Australian iron ore grades, a major difficulty is that grades are estimated based on saleable production and not raw ore, despite the majority of iron ore requiring beneficiation before use (Mudd, 2009a, 2010b) Despite the issues with the data, the longterm trend is a gradual ore grade decline for saleable iron oreIron ore in Australia and the world: Resources, production

Iron ore beneficiation: an overview ScienceDirect

2023年1月1日 24 Beneficiation methods Beneficiation is a process where ore is reduced in size and valuable minerals are separated from the gangue minerals Separation of valuable minerals from gangue minerals can be efficiently achieved by taking advantage of the differences in physical, surface, and magnetic properties2016年1月28日 The large scale iron ore beneficiation plant specially designed for slimes and low grade fines is located in Bailadila region by ESSAR group It uses ball mill, spirals, high gradient magnetic separation and thickener as main processing units Beneficiation plants in iron ore processing were installed in Barbil region by BRPL based on allflux Advances in Low Grade Iron Ore Beneficiation MECON