Tertiary Mining Mill For Rocks

2022-03-04T06:03:40+00:00

Ultrafine grinding and mechanical activation of mine waste rock

2015年2月14日 Jiajie Liand Michael Hitch, Ultrafine grinding and mechanical activation of mine waste rock using a highspeed stirred mill for mineral carbonation, Int J Miner Metall Metall Mater , 22(2015), No 10, pp 10051016Contribute to chengxinjia/ development by creating an account on GitHub/ primary secondary tertiary mining millsmd at main 2022年10月4日 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described The main factors influencing rock Reduction of Fragment Size from Mining to Mineral

ITP Mining: MinetoMill Optimization Energy

2012年11月14日 MinetoMill Optimization Using MinetoMill Technology to Optimize Crushed Stone Production Historically, the production of a mineral commodity has been Companies Buyer's Guides Crushers, breakers and grinding mills for the mining industry Crushing is used to reduce the size of runofmine (ROM) ore for further processing Crushers, breakers and grinding mills for the mining industry2015年9月10日 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and 11192 Crushed Stone Processing and Pulverized

RocktoMetal Ratio: A Foundational Metric for Understanding Mine

2022年4月25日 Abstract The quantity of ore mined and waste rock (ie, overburden or barren rock) removed to produce a refined unit of a mineral commodity, its rocktometal The TAKRAF sizer portfolio covers primary and secondary (as well as tertiary) sizing applications Our Standard Class Sizers offer a highly optimized and economical solution while our XTREME Class Sizers Sizers TAKRAF TAKRAF GmbHCrushers have more efficient transfer of applied power to the breakage of rock than grinding mills Typically a crushing flowsheet for a mineral processing plant will have from onetothree stages of crushingAMIT 135: Lesson 5 Crushing – Mining Mill

Energy and Environmental Profile of the US Mining

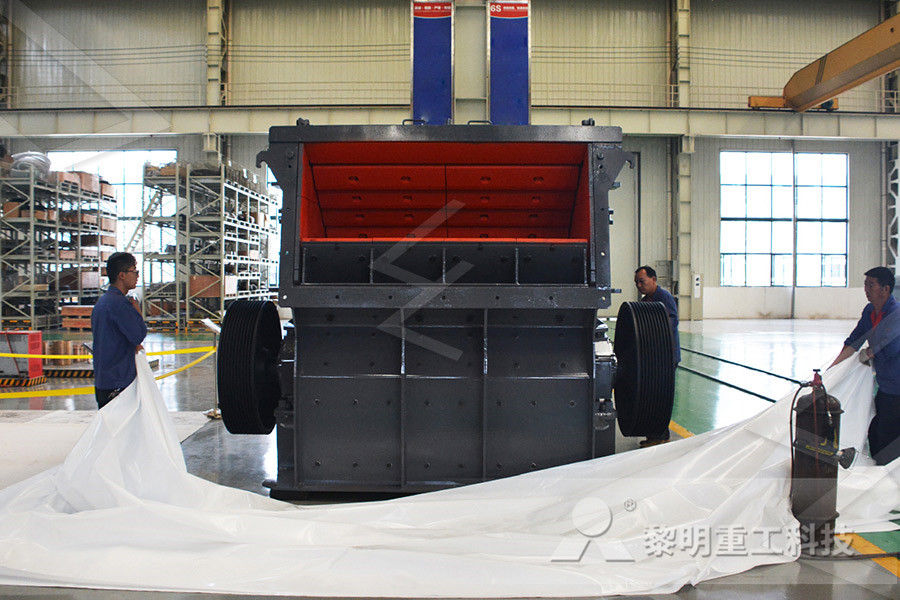

2013年11月8日 Following blasting, the fragmented ore is loaded on a mining truck and hauled to the crusher for primary crushing Many mines employ two to three stages of crushing Some mines have the primary crusher located in the mine, using conveyors to transport the crushed ore to the secondary and tertiary crushers or directly to the millsHammermill Crushers Hammermill Crushers are known for providing greater reduction ratios in a variety of materials for the aggregate and industrial markets The heavyduty, rugged construction of all Universal McLanahan Hammermill Crushers2016年2月24日 gyratories expected soon, as well as secondary and tertiary machines of up to 3,000 mm (120 in) • Rising energy costs are causing owners to increase the integration of mine and mill design, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed Crushing Plant Design and Layout Considerations 911

secondary crushing Mining Quarry Plant

2013年3月12日 Three in One Mobile Crusher limestone mobile crushing plant used in Qatar South Africa 30 tph limestone grinding plant Limestone grinding line in Kazan Russia South Africa 200 tph granite crushing line Philippines 150TPH Riverstone Crushing Plant Indonesia 180 tph Iron Ore crushing plant How Much VSI Sand Crusher2016年7月12日 The Hadsel mill (see Fig 12) is a new type of wet crushing device which has found limited but interesting application A large wheel, up to 24 ft in diameter by 4½ ft wide, is fitted with internal buckets As the wheel revolves, the buckets lift the rock to the top of the mill where it is dropped onto stationary breaker platesCrushing Screening Plant 911 MetallurgistOur Hammer Crushers offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to mediumhard rock They offer a very high crushing ration of 10:1 up to 80:1 The product is ideal as feed material to downstream ball mills or vertical roller mills Double rotor Hammer Crushers are able to process Hammer Crushers

Limestone and Crushed Rock Department of Energy

2013年11月8日 mining operations For example, in 2000 the amount of crushed rock produced was 17 billion tons With an average ore recovery ratio of 94 percent, the amount of waste material produced was 130 million tons This calculates to a total of 18 billion tons of materials handled in crushed rock mining Figure 92 Materials Handled for Crushed The TAKRAF sizer portfolio covers primary and secondary (as well as tertiary) sizing applications Our Standard Class Sizers offer a highly optimized and economical solution while our XTREME Class Sizers offer maximum reliability in the most extreme conditions Download our latest sizer brochure here: TAKRAF XTREME Class SizersSizers TAKRAF TAKRAF GmbH2015年9月10日 Tertiary crushing is usually performed using cone crushers or other types of impactor crushers Oversize material from the top deck of the sizing screen is fed to the tertiary crusher The tertiary crusher output, which is typically about 050 to 25 centimeters (3/16th to 1 inch), is returned to the sizing screen11192 Crushed Stone Processing and Pulverized

Improving energy efficiency in comminution

2018年10月1日 SLW: Another example of improving wear life for increased mill performance, including reduced specific energy consumption, is given in a paper by Sever Ciutina ( MLS) and RJSoriano (Senior A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces secondary, and tertiary crushers Hammer mill crushers use continuous hammer blows to shatter and Types of Crushers: What You Need to Know Machinery 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics

Size Reduction and Energy Requirement ScienceDirect

2016年1月1日 The energy for crushing, E, is the difference between the energy of the input pendulum and the energy of the rebound pendulum and is computed from the following expression: (319) ɛ E = E S 1 − ɛ 2 M B M B + M S Units: energy terms ( E ) = kWh/t = 3600 kJ/t mass = kg the value of ɛ = 0–02Contribute to chengxinjia/ development by creating an account on GitHub/ primary secondary tertiary mining millsmd at main Contribute to changjiangsx/ development by creating an account on GitHub/ primary secondar tertiary gold minnningmd at

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Heavy mining, quarried materials, sand gravel, recycling: Gyratory crushers: Soft to very hard: Abrasive: Dry to slightly wet, not sticky: 4/1 to 7/1: Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates Semiautogenous mills are basically the same autogenous mills, but with the addition of 2015年7月27日 Address: 7 Lantana St Blackburn North Vic 3130 Contact Person: Bohdan Blaszczyk Phone: +61 3 9877 7777 Fax: +61 3 9877 8177 Mobile: 0411 099 989 : Optimized by NetwizardSEOau Optimized by: Netwizard SEO Mining operations are one of the last pioneering ventures on our planetDIFFERENT TYPES OF SCREENS USED FOR MINING Hawk 2016年3月10日 To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushingCrushing Plant Flowsheet DesignLayout 911 Metallurgist

Cone crushers for demanding crushing needs

Engineered for all rock types, ® GP Series™ cone crushers can be utilized as secondary, tertiary, and quaternary crushers in aggregates production plants and in mining operations ® GP Series™ cone crushers are allround crushing machines enabling smooth crushing process adaptation and full automation2014年7月18日 In recent years, autogenous crushers have been adapted for crushing runofmine rock in primary crushing circuits Consequently, autogenous mills hav e increased in im portance as a means of crushing and grinding In autogenous crushers, the rock to be crushed also provides the crushing forceSAND, GRAVEL, AND CRUSHED STONE ONTHEJOB