Zinc Lead Ore Dressing

2023-01-29T16:01:05+00:00

Beneficiation of LeadZinc Ores – A Review: Mineral

2021年3月28日 This paper summarizes the classification of ore deposits and different beneficiation techniques that are currently employed for the treatment of leadzinc ore Froth flotation is the most widely used beneficiation technique2016年10月1日 Wu Luqing, Zhang Xiaolin, Li Kangkang, Liu Dianwen Overview of Leadzinc Oxide Ore Dressing Technology in China[J] Multipurpose Utilization of Mineral Overview of Leadzinc Oxide Ore Dressing Technology in China2018年4月16日 The study ore specimen is pyrite lead–zinc ore with dominance of iron disulfides (pyrites, arsenopyrites, marcasite) The specimen contains in total above 40% MINERAL DRESSING Effect of a Crushing Technique on

Lead Zinc Processing Solution Mineral Processing

2023年9月28日 The leadzinc ore beneficiation aims to separate valuable metal components such as lead and zinc from raw ore and remove impurities, mainly including 2021年11月1日 At the Huili leadzinc dressing plant, flotation of leadzinc sulfide ore was divided in two parallel series, each of which had the process capacity of 522 tons/day Efficient flotation recovery of lead and zinc from refractory leadzinc 2019年12月27日 The sample used in this study was oxidized leadzinc ores from Kayseri (Turkey) The ore contains lead and zinc with major mineralization of smithsonite and MINERAL DRESSING Beneficiation of Oxidized Lead–Zinc

CuPbZn, CopperLeadZinc Ores, Copper Lead Zinc

Xinhai CuPbZn Ore Dressing Process It is reported that more than 90% of nonferrous metal ores (copper, lead, zinc, etc) adopt flotation process, especially for those with fine According to the different flotability and floating speed among copper, lead, zinc ore, Xinhai separately obtains copper concentrate, lead concentrate and zinc concentrate from the slurry Application Simple mineral leadzinc separation, lead zinc beneficiation 2022年10月11日 With the gradual reduction of easytodress ore, complex multimetal difficulttodress ore will be a major problem in the future [ 6, 7, 8 ] Lead and zinc exist in nature mostly as sulphide and are often Characterization of Discarded Lead–Zinc Sulfide

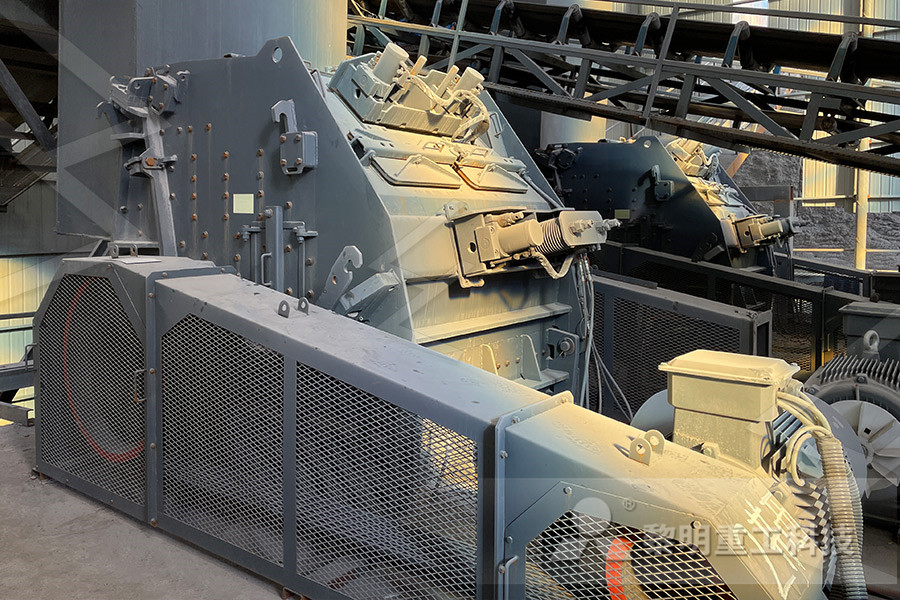

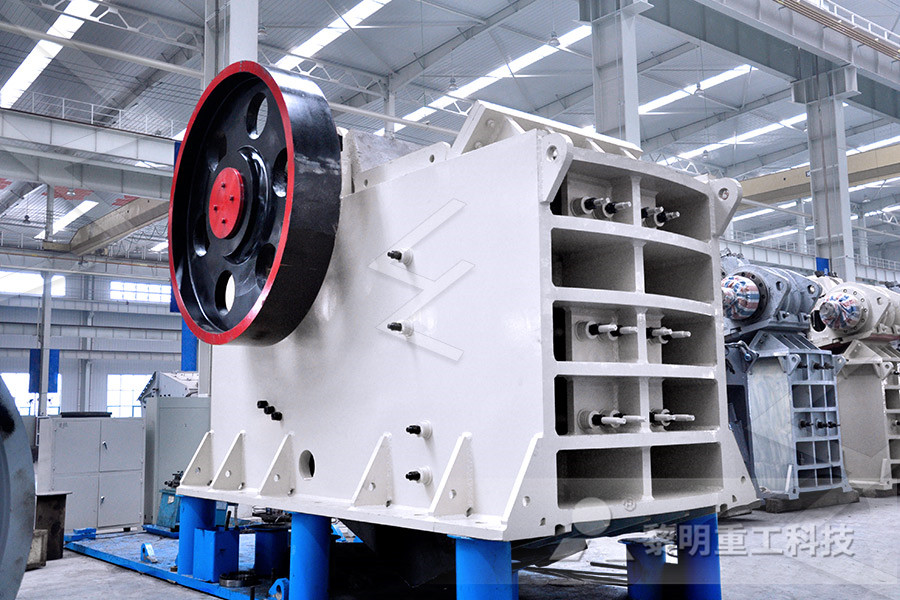

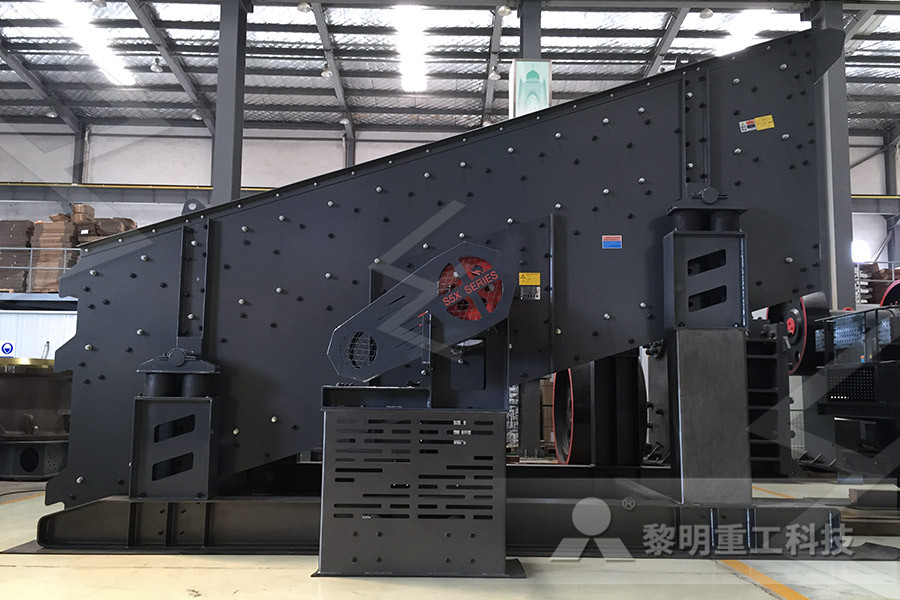

Lead and Zinc ore dressing Mining and Mineral

The Lead and Zinc ore dressing, according to the different types of ore, then choose different ore dressing methods, also need different leadzinc ore beneficiation equipment2020年8月22日 Copperleadzinc mixed ore in Tibet, China, is a complex and refractory polymetallic ore resource; thus, ascertaining its mineralogical properties is very important for comprehensive recovery of valuable elements In this work, the mineralogical properties of this copperleadzinc mixed ore have been characterized in detail following a Multianalysis Characterization of Mineralogical Properties of 2016年6月2日 With most ores containing lead and zinc sulphides, the production of a separate lead concentrate for shipment to the lead smelter, and of a separate zinc concentrate to ship to the zinc smelter, makes for Mineral Processing and Ore Dressing 911

Zinc treatment charges jump after 2022 smelter

17 小时之前 The zinc market was defined by smelter woes last year with global refined metal production dropping by 41% relative to 2021, according to the International Lead and Zinc Study Group (ILZSG)2021年2月4日 Collector type and pulp pH play an important role in the lead–zinc ore flotation process In the current study, the effect of pulp pH and the collector type parameters on the galena and Critical importance of pH and collector type on the flotation 2020年4月2日 In this study, sulfuric acid leaching and gravity shakingtable separation by shaking a table are used to extract lead and zinc from a PbZn oxidizing roasting cinder The oxidizing roasting cinder—containing 169% Pb, 305% Zn, 103% Fe and 251% S—was obtained from a PbZn sulfide ore in the Hanyuan area of China by a flotationrotary kiln Metals Free FullText Extraction of Lead and Zinc from a

Leaching of heavy metals from leadzinc mine tailings and

2022年3月1日 The particle size of leadzinc mine tailings was analyzed by Nano Measurer 12 software, and the results were showed in Fig S1 The unpolluted soils were collected from a paddy field (26°17′3570″ N, 107°54′576″ E) and used to identify the characteristics of The properties of Leadzinc mine tailings2005年2月1日 Oxide lead–zinc ore sample containing 1017% Pb, 1098% Zn, 57 g/t Ag and 164 g/t Cd was subjected to this experimental study and taken from Kayseri located in the foothills of the Aladağ Mountains, TurkeyPreliminary flotation tests with the ore sample indicated that there was no selectivity in terms of zinc recovery; therefore studies were Flotation of Aladagˇ oxide lead–zinc ores ScienceDirect2021年5月31日 Ore blending is an essential part of daily work in the concentrator Qualified ore dressing products can make the ore dressing more smoothly The existing ore blending modeling usually only considers the quality of ore blending products and ignores the effect of ore blending on ore dressing This research proposes an ore blending modeling method Applied Sciences Free FullText A Method of Ore Blending

Mineral Processing and Metallurgical Treatment of Lead Vanadate

2020年2月22日 Depending on the ore composition in sulfide scavenger flotation, sphalerite as zinc concentrate II or mixed leadzinc concentrate were recovered The scavenger section consisted of rougher and one cleaner with copper sulfate, a mixture of amyl and ethyl xanthates (1:2), and Aerofloat 25 were applied as reagents2023年8月30日 In the beneficiation process, the sulfide leadzinc ore is mainly flotation Among them, the proportion of zinc ore in most leadzinc ore is higher than that of lead ore Therefore, in the actual process, the method of “suppressing zinc and floating lead” is generally adopted Main principles to deal with leadzinc sulfide oreFlotation of LeadZinc Sulfide Ore Mineral ProcessingA copperleadzinc ore dressing plant in Sweden with the daily output of 1000t, copper content of 058%, lead content of 285% and zinc content 490%; Xinhai adopted copperlead mixed flotation Final copper CuPbZn Dressing Process xinhaimineral

New Ideas for the Design of Green Smelting Project of Domestic Lead

2020年1月25日 During the years of stable operation, the Zhuzhou smelter has continuously increased the percentage of secondary materials charged to the smelting process in form of solid wastes and hazardous wastes, including purchased materials such as lead floating dressing, lead raw ore, lead –zinc mixed ore, high gold ore, lead mud, lead sand as well 2021年11月9日 A representative sample of lead–zinc ore enrichment tailings from Belousovskaya Enrichment Plant (East Kazakhstan region) was taken as the object of research The ore sample was provided with a Optimization of Conditions for Processing of 2017年3月12日 Abstract Gravity separation is an industrial method of separating two components, either in suspension, or in dry condition, from a granular mixture different specific weights The process of (PDF) GRAVITY SEPARATION IN ORE DRESSING ResearchGate

Characterization of Discarded Lead–Zinc Sulfide Ore Tailings

2022年10月11日 The lead–zinc ore is a typical lowgrade complex polymetallic sulphide ore Its typical mineralogy is characterized by a high content of cryptocrystalline graphite, low content of lead, zinc, and copper, and fine grain size However, the aggregation size of sulfide mineral aggregations is coarse, and the symbiotic relationship is relatively simple The important minerals in zinc ores are sphalerite (ZnS), zincite (ZnO), franklinite [ZnO (Fe,Mn)2 O 3 ], calamine [Zn 2 (OH) 2 SiO 3 ], and smithstone (ZnCO 3 ) Zinc ores normally contain 5–15% zinc Approximately 80% of zinc mines are underground mined, 8% are mined from open pits, and the remainder are a combination of both ores ( Ray et Zinc Ore an overview ScienceDirect Topics2020年4月2日 the process for leadzinc ore can be divided into three categories: selective flotation; bulk flotation; and The sample was collected from the PbZn sulfide ore dressing plant by the (PDF) Extraction of Lead and Zinc from a Rotary Kiln

(PDF) Characterization of Discarded Lead–Zinc Sulfide Ore

2022年10月11日 The lead–zinc ore is a typical lowgrade complex polymetallic sulphide ore Its typical mineralogy is characterized by a high content of cryptocrystalline graphite, low content of lead, zinc It is reported that more than 90% of nonferrous metal ores (copper, lead, zinc, etc) adopt flotation process, especially for those with fine grain and complex symbiosis Flotation process can achieve ideal separation effect, and separately recover lowgrade ore then enrich multiple highgrade concentratesCuPbZn, CopperLeadZinc Ores, Copper Lead Zinc 2017年4月10日 Oredressing methods fall naturally into two general subdivisions— (1) concentration methods and (2) directrecovery methods (amalgamation and leaching or wet methods) Concentration methods are employed to remove worthless gangue material and concentrate the valuable minerals of the crude ore in a smaller bulkOre Dressing Methods 911 Metallurgist