Mining Mill For Dead Materials

2020-10-01T09:10:43+00:00

Reduction of Fragment Size from Mining to Mineral

2022年10月4日 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described The main factors influencing rock fragmentation by blasting are analysed Main models for predicting rock fragmentation are briefly 2022年4月1日 Mine wastes are generated during open pit and underground mining activities and include waste rock, overburden, and mining waters Mineral processing Review on advances in mineral processing technologies 2021年11月22日 Using these waste materials as mine paste backfill material appears to be a viable solution to surface waste accumulation This review’s content helps to promote Utilization of mill tailings, fly ash and slag as mine paste

Towards mine tailings valorization: Recovery of critical materials

2020年8月1日 What critical materials can be recovered from mine tailings? What are the challenges in the production of critical materials using mine tailings as a source? In 2022年4月30日 Cisternas et al (2021) use value retention options (ReX) of refuse, reduce, resell/reuse, repair, refurbish, remanufacture, repurpose, recycle materials, recovery of A review of circular economy strategies for mine tailings2023年3月2日 The gold extraction process from smallscale mining yields pulverized rock byproducts called mill tailings (Behera et al 2021 ) These residues are disposed to be Valorization of waste mill tailings from smallscale mining

Use of iron mine tailing as fillers to polyethylene

2021年3月29日 Among the mining industry tailings and byproducts described in the literature acting as polymer additives are: (1) bauxite mining byproducts (Al 2 O 3, red 2021年11月3日 Medium and highly sulfidic tailings are highvolume wastes that can lead to severe environmental damage if not properly managed Due to the high content of sulfide minerals, these tailings can undergo Sustainability Free FullText Exploring the 2021年11月1日 At present, mine backfill treatment of solid waste mainly includes two methods: (I) using active solid waste material as admixture to reduce the consumption of Utilization of mill tailings, fly ash and slag as mine paste

Critical Mineral Recovery Potential from Tailings and Other Mine

2019年9月23日 Publications The primary objectives of this oneyear scoping project are to determine the feasibility of extracting byproduct mineral commodities, such as critical 2021年4月20日 for minetomill material tracking Martin Servin 1, Folke Vesterlund, and Erik Wallin † April 20, 2021 Abstract Systems for transport and processing of granular media are challenging to analyse, operate and optimise In the mining and mineral processing industries these systems are chains of proDigital twins with distributed particle simulation for mine 2021年1月19日 Tumbling mills have been widely implemented in many industrial sectors for the grinding of bulk materials They have been used for decades in the production of fines and in the final stages of ore comminution, where optimal levels for the enrichment particlesrsquo; sizes are obtained Even though these ubiquitous machines of relatively Tumbling Mills Encyclopedia MDPI

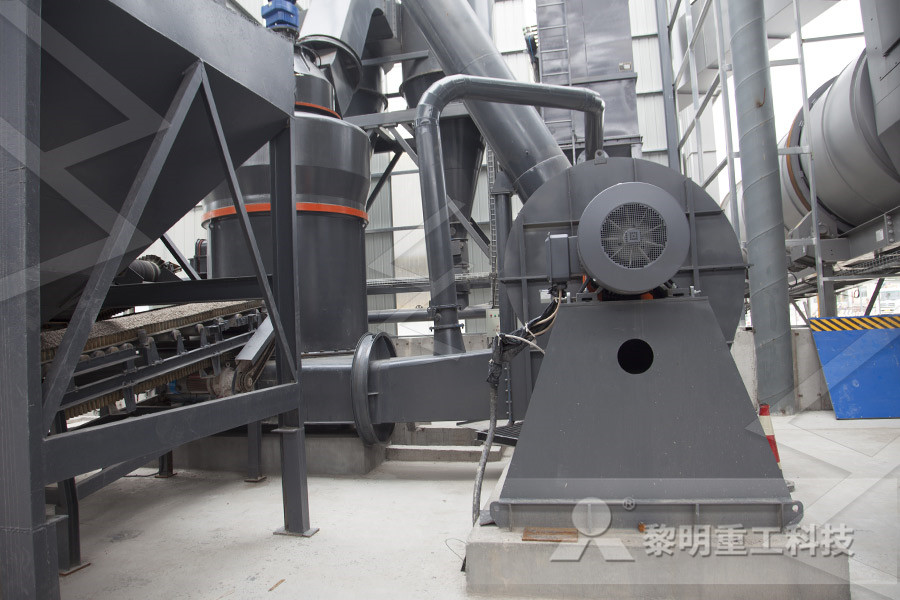

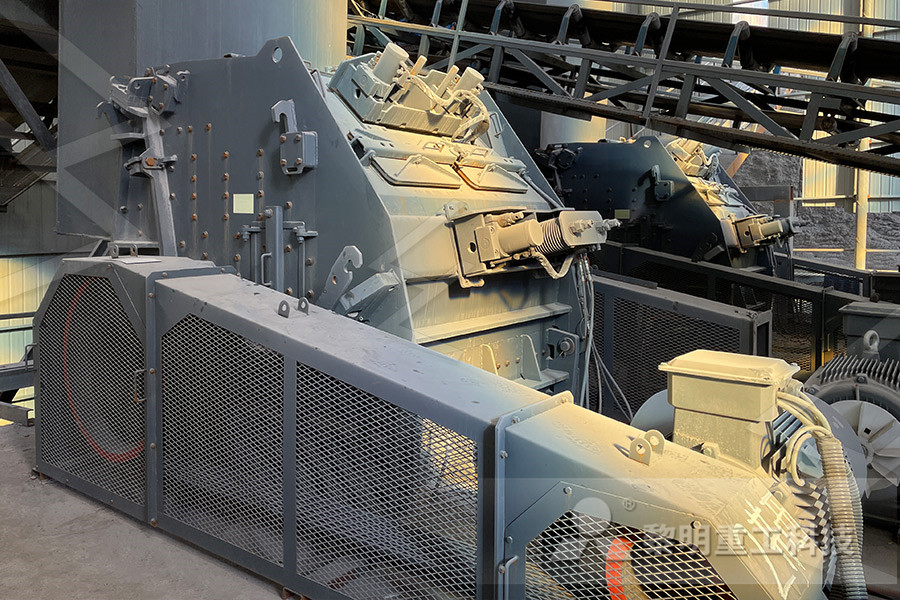

Mining feeders for consistent control

In control We have engineered our feeders to easily handle highimpact feeds of heavy, coarse and sharp materials from trucks, surge piles, bins and hoppers – as they provide a controlled flow of the material to the next stage in the process Feeders also can deliver volumetrically regulated feed and even metering to prevent material floodingChina Mine Mill catalog of Rock Phosphate Roller Marble Dolomite Lime Powder Grinding Raymond Mill Machine Grinding Mill Machine Price for Mining, Professional Mining Equipment Gypsum Limestone Powder Making Raymond Grinding Mill Machine provided by China manufacturer Jiangxi Province County Mining Machinery Factory, page1Mine Mill Jiangxi Province County Mining Machinery 2021年5月25日 Related work includes the datadriven minetomill framework proposed and tested in [19,20] It was concluded that material tracking needs to be performed in a more comprehensive way to better connect mining and mineral processing data, as well as stockpile management, and the required infrastructure was found to be the main MinetoMill Material Tracking DiVA

Mining Wastes as Road Construction Material: A Review

2023年1月6日 The mining industry manages large volumes of tailings, sludge, and residues that represent a huge environmental issue This fact has prompted research into valorization of these wastes as alternative aggregates for concrete production, embankments, pavement material, etc The use of mining wastes as a resource for 2022年6月1日 The aim of the study is to investigate digital technologies for measuring, monitoring and tracking ore material from the mining face and reporting in real/near real time on a dashboard in a control room on surface The fourth phase is a minetomill reconciliation analysis using historic data to identify trends and insights in the dataThe tracking of metal content on a surface mine: A digital mining 1 Physical cleaning: in this route, cleaning is achieved by mechanical effect obtained by milling a hard material that abrades the undesired materials 2 Chemical route: in this route the balls What is the cleaning process for balls in Ball mill process

Mine operating costs and the potential impacts of energy and

2014年2月1日 It is noteworthy that the mean relative Mine and Mill costs for the preliminary and operating mine reports were of a similar magnitude to the overall and adjusted data presented in Table 2, Table 3 The relative G A costs of the operating mines were the highest (137 ± 25%), followed by feasibility report estimates (114 ± 37%) and 2022年9月1日 This review is divided into seven sections (Fig 1) with the goal of providing a summary of energyefficient and environmentally conscious extraction and processing of minerals in the age of digital transformationThe introduction provides background information and explains existing problems In the energy consumption and innovative The minerals industry in the era of digital transition: An 2021年5月15日 Servin et al (2021) provide an example of a system for tracking material from mine to mill using digital twin technology Kumar and Dimitrakopoulos (2022) describe a system for updating (PDF) Digital Twins with Distributed Particle Simulation for Mine

(PDF) Mining Activities, Cement Production Process and

2022年7月4日 Cement has hydraulic properties like slaked lime and hardens when mixed with water Compressive strength increases in time and reaches its practical top limit after 28 days Mixing crushed stone 2020年11月12日 Mining and processing of lithium, however, turns out to be far more environmentally harmful than what turned out to be the unfounded issues with fracking In May 2016, dead fish were found in the waters of the Liqi River, where a toxic chemical leaked from the Ganzizhou Rongda Lithium mine Cow and yak carcasses were also The Environmental Impact of Lithium Batteries IER大量翻译例句关于"mill mining" – 英中词典以及8百万条中文译文例句。 翻译器 Translate texts with the world's best machine translation technology, developed by the creators of Lingueemill mining 英中 – Linguee词典

Lead processing Mining, Concentrating, Refining Britannica

Lead processing Mining, Concentrating, Refining: Once the ore is removed from veins (narrow channels) or lodes (roughly spherical deposits) in the Earth, usually at depths of about 60 metres, the ore is treated at concentrating mills Here the ore is finely crushed, sometimes to particle diameters of less than 01 millimetre (0004 inch), and then treated 2021年3月29日 The iron mine tailing materials produced using batch mixing showed more significant modifications in the properties due to the better dispersion of the filler as shown by scanning electron Use of iron mine tailing as fillers to polyethylene2016年1月1日 For a single mine, average comminution energy consumption can be approximately 6,700 kWh /kiloton Grinding is accomplished by abrasion and impact of the ore with moving media such as rods (rod mills), balls (ball mills), or Energy Consumption in Mining Comminution ScienceDirect

Sustainability Free FullText InPit Disposal of Mine MDPI

2023年4月11日 In the next decades many of the old tailings storage facilities (TSFs) could be reprocessed if one considers the prices of metals, new uses of metals which today are not valuable, and the application of new, more efficient metallurgical technologies In this context, inpit disposal of mine tailings (IPDMT) is an attractive alternative to be used as