High Capacity Low Energy Mining Mill

2021-09-17T05:09:54+00:00

Helping to reduce mining industry carbon emissions: A step

2022年3月30日 Tozlu and Fresko (2015) estimated that the total installed motor capacity of AG/SAG mills in hard rock mining in 2015 was 58 million kW (see Fig 1) Given that mining industry activity has been relatively slow since then, additional sales of AG/SAG mill 1 天前 Although 60% of total energy is estimated to be consumed in mining equipment, this category covers a very wide variety of different equipment Comminution, consuming MINING ENERGY CONSUMPTION 2021 CEEC (Coalition for 2021年2月26日 It is performed in mills, which are machines of high rotational masses The start of a mill filled to capacity requires Energy Efficiency Analysis of Copper Ore Ball Mill

MINING ENERGY CONSUMPTION 2021 Mining

2021年12月28日 Figure 1 shows a high level energy flow on a copper mine, as determined in this study Although 60% of total energy is estimated to be consumed in mining 2022年3月1日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO2 emissions by up to 345 megatonnes/year, or 435% when compared to the established Helping to reduce mining industry carbon 2022年9月1日 1 Introduction A transition to a low carbon society is a challenge that will require vast amounts of metals and minerals The easiesttomine ores have already Towards waterless operations from mine to mill ScienceDirect

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021年3月24日 The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading One method for increasing the energy efficiency of ball mills is Mining capacity for critical minerals needs to expand swiftly to get on track with net zero goals While current anticipated investments will lead to substantial gains, capacity would Mining and materials production – Energy Technology IEA2022年11月27日 Introduction The current effects of climate change have created a worldwide consensus on the need for decarbonization [ 1 ] In order to achieve the 2030 emission reduction task announced by Mining Free FullText Electrification Alternatives

Process effluents and mine tailings: sources,

2016年12月19日 Further, mining, minerals and energy supply networks play an important role in IWRM implementation Mine and other process operations effluent and tailings management systems can impose long It is generally accepted that practical mill power (PM ) is a function of mill capacity and diameter, ie,P M = Mill Constant * (Mill Diameter ) n where n = 03 to 05 It is evident that mill power is a function of the height at which AMIT 135: Lesson 7 Ball Mills Circuits – Mining 2023年10月4日 Yes, the number of impacts will be lower but that affects capacity not efficiency What is important for efficiency is the location of the energy spectra (high impacts vs low impact) For ball mills low impact is more important because of the smaller particlesBall Charge and Grinding Efficiency 911 Metallurgist

Ball Mill an overview ScienceDirect Topics

A feature of ball mills is their high specific energy consumption A mill filled with balls, working idle, consumes approximately as much energy as at fullscale capacity, that is, during the grinding of material Therefore, it is most disadvantageous to use a ball mill at less than full capacity2021年4月19日 Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, resulting in higher mill throughput in many mines, but also (PDF) Feasibility and necessity of mine to mill optimization in mining Rule 1: Always use a jaw crusher if you can due to lower costs Rule 2: For low capacity applications, use jaw crusher and hydraulic hammer for oversize Rule 3: For high capacities, use jaw crusher with big intake openings Rule 4: For very high capacities, use gyratory crusherAMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

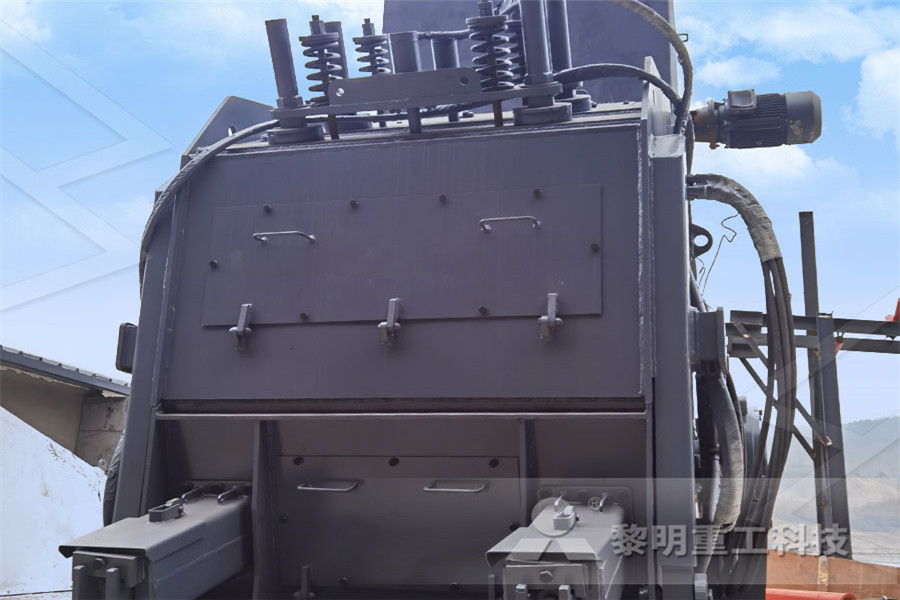

High Capacity Low Energy Mining Grinding Rod Mill For Sale Buy High

High Capacity Low Energy Mining Grinding Rod Mill For Sale , Find Complete Details about High Capacity Low Energy Mining Grinding Rod Mill For Sale,High Capacity,Low Energy,Mining Grinding Rod Mill from Supplier or ManufacturerHenan Xingyang Mining Machinery Manufactory2021年9月4日 33 Low energy efficiency and high emissions of coal utilization As a highcarbon energy source, coal will inevitably bring about carbon emissions during the process of utilization China’s CO 2 emissions per unit of GDP are much higher than those of developed countries, and its total emissions now rank first in the world The energy The view of technological innovation in coal industry under In highenergy ball milling, vacuum or a specific gaseous atmosphere is maintained inside the chamber Highenergy mills are classified into attrition ball mills, planetary ball mills, vibrating ball mills, and lowenergy tumbling mills In highenergy ball milling, formation of ceramic nanoreinforcement by in situ reaction is possibleMilling Energy an overview ScienceDirect Topics

MINING ENERGY CONSUMPTION 2021 CEEC (Coalition for

1 天前 A highlevel study into mining energy use for the key mineral commodities of the future Author Marc Allen, Technical Director, engeco iron ore, nickel and lithium Bringing together mine energy use data from more than 40 published studies (each of which references dozens more studies and hundreds of mining operations) from 2007 to 2020 2016年7月13日 Tests can be completed at minimal cost within 4 to 6 weeks Reliable scaleup procedures are provided Polycom highpressure grinding roll pilot plant facilities are available for gold mining companies HPGR High Pressure Grinding Rolls 911 Where HPGR technology has replaced traditional methods of crushing and grinding (eg SAG or ball mills), it has: Provided excellent throughput capacity and energy efficiency Decreased energy consumption by up to 40% Substantially reduced water consumption Reduced recirculation and wear within crushing and grinding circuitsOur Dynamic HPGR Technology for Mineral Grinding Weir

Decarbonization in steel McKinsey

2020年6月3日 Power supply 12 Assuming approximately 35 and 130 megawatthour installed capacity per wind turbine, respectively Assumed utilization 25 percent Hence, availability, steady supply, and competitive 2021年3月24日 The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading One method for increasing the energy efficiency of ball mills is to optimize their drive systems This article looks at two variants of drive systems with efficiencies higher than the already existing solutions The first variant is a low Energy Efficiency Analysis of Copper Ore Ball Mill Drive ObserverBased and Regression ModelBased Detection of Emerging Faults in Coal Mills Peter Fogh Odgaard, Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007 52 Experiments with and design of the regression modelbased approach Operating data from a coal mill is used to compare the fault detection Coal Mill an overview ScienceDirect Topics

Ball Mill an overview ScienceDirect Topics

The history and necessity of mechanical alloying M Sherif ElEskandarany, in Mechanical Alloying (Second Edition), 2015 2515 Planetary ball mills The Planetary ball mills are the most popular mills used in MM, MA, and MD scientific researches for synthesizing almost all of the materials presented in Figure 11 In this type of mill, the milling media have 2020年2月5日 The mood was apprehensive as data scientists, metallurgists, and engineers from FreeportMcMoRan filed into the control room of a copperore concentrating mill in Bagdad, Arizona, on the morning of October 19, 2018 They had come to learn what would happen when they cranked the big mill up to a work rate that had never been tried Inside a mining company’s AI transformation McKinsey2014年2月1日 In mining industries, there are two main operating costs related to grinding mills operation, namely energy consumption, mill liner and grinding media wear [1, 2] Grinding mills represent up to Mine operating costs and the potential impacts of energy

HighEnergy Ball Milling an overview ScienceDirect Topics

212 Highenergy ball milling Highenergy ball milling is a mechanical deformation process that is frequently used for producing nanocrystalline metals or alloys in powder form This technique belongs to the comminution or attrition approach introduced in Chapter 1 In the highenergy ball milling process, coarsegrained structures undergo 2022年1月25日 Higher coking coal prices increase the cost penalty incurred by steelmakers, leading to higher price penalties for lowgrade iron ores (Exhibit 2) This could affect overall iron ore price dynamics in two different ways, depending on the level of total iron ore demand In one scenario, if total demand for iron ore can be met solely with high High coking coal prices provide glimpse into steelmaking’s