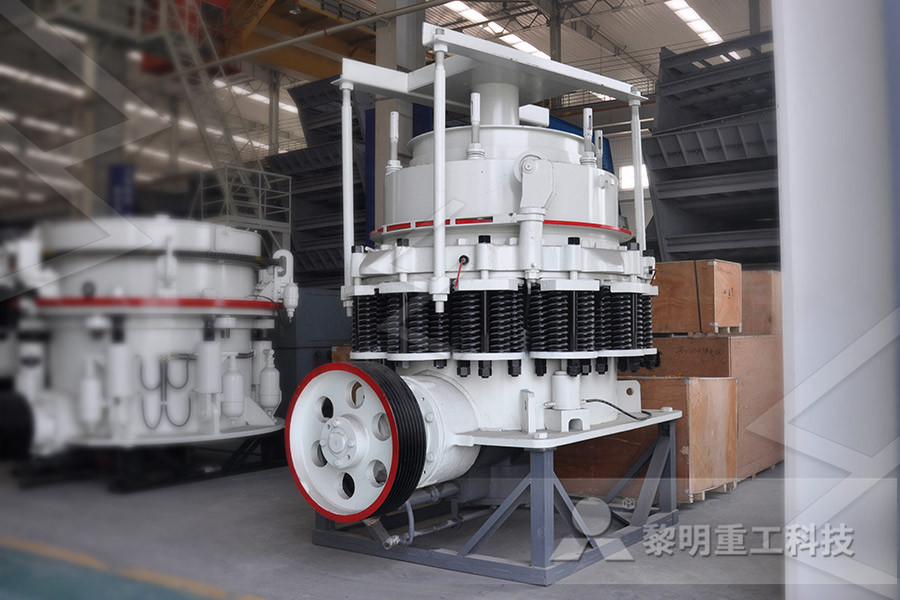

High Performance Japanese Technology Af Cone Crusher

2023-10-24T17:10:39+00:00

HPC CONE Crushing/Grinding EARTHTECHNICA

2021年11月4日 HIGH PRESSURE CRUSHING AND HIGH PERFORMANCE CONE CRUSHER HPC Cone Crusher is developed to achieve high crushing ratio and high throughput capacity with newly 2023年3月12日 Japanese Technology Af Cone Crusher (AF series), Find Details and Price about Crusher Cone Crusher from Japanese Technology Af Cone Crusher (AF series) [Hot Item] Japanese Technology Af Cone Crusher (AF series)2023年1月20日 The ® HP SeriesTM for aggregates When you need a crusher for aggregates production, the HP Series cone crushers are the ideal choice HP Series cone crushers – High performance

AF Series Hydraulic Cone Crusher Luoyang Dahua

2023年7月24日 AF series cone crusher is a kind of highefficient fine cone crusher that manufactured by our compan It applied the advanced laminated crushing technique at Find AF CONE CRUSHER, AF CONE CRUSHER from LUOYANG DAHUA HEAVY TYPE MACHINERY CO, LTD in China As a reliable CRUSHER supplier, we offer highquality AF CONE CRUSHER, AF CONE CRUSHER LUOYANG DAHUA It is one kind of fine crushing machine with high performance AF Cone Crusher applies laminating crushing technique, appropriate eccentric distance, adjustment of discharge AF Cone Crusher (Technical Cooperation with Japan) form

New developments in cone crusher performance optimization

2009年6月1日 With today’s technology, crusher design development is still somewhat restrictive The ability to investigate crusher variables such as cavity profile, throw, 2023年7月11日 Japanese Technology Minyu Compound Hydraulic Rock Cone Crusher, Find Details and Price about Rock Cone Crusher Symons Cone Crusher from Japanese Japanese Technology Minyu Compound Hydraulic Rock Cone Crusher 2009年10月1日 Based on the analysis and modeling above, it is possible to carry out the optimization of the cone crusher parameters to improve the performance of the crusher Analysis and optimization of cone crusher performance

AF Series Hydraulic Cone Crusher Luoyang

2023年9月13日 AF series cone crusher is a kind of highefficient fine cone crusher that manufactured by our company through adopting advanced technology from abroad It applied the advanced laminated crushing The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable crushing plants The hydraulic Cone Crushers Moore Watson Ltd2009年6月1日 Compression cone crusher designs today have evolved from the simple cone crusher first developed in the mid1920s by Edgar B Symons, to the modern high performance crushers Early crushers used springs for tramp iron protection and were manually adjusted The newer crushers utilize a safer more reliable hydraulic tramp New developments in cone crusher performance optimization

AF CONE CRUSHER, AF CONE CRUSHER LUOYANG DAHUA

Find AF CONE CRUSHER, AF CONE CRUSHER from LUOYANG DAHUA HEAVY TYPE MACHINERY CO, LTD in China As a reliable CRUSHER supplier, we offer highquality products on TradeAsiaCone crushers have gained such wide acceptance that they may be regarded as standard in the intermediaterange sizereducing machines A schematic diagram of a cone crusher is shown in Fig 46 AThe drive is similar to that of a gyratory crusher The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the Cone Crusher an overview ScienceDirect Topics13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics

Crusher an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct drive2009年10月1日 Cone crusher optimization Based on the analysis and modeling above, it is possible to carry out the optimization of the cone crusher parameters to improve the performance of the crusher The objective of cone crusher optimization is the maximal output of the cone crusher, as shown in Eq (7) The product quality including particle size and Analysis and optimization of cone crusher performance2022年1月21日 The ® HP Series™ cone crusher product family includes altogether ten models HP100 HP200 HP300 HP400 HP500 HP900 HP3 HP4 HP6 HP Series cone crushers provide predictable and consistent capacity, end product size, gradation and shape, making them a safe choice for aggregates and mining processes HP Series cone crushers – High performance

Development of wear model for cone crushers ScienceDirect

2006年8月30日 Hydroset pressure and power draw were read off the control panel of the crusher once every day When the inlet bin of the crusher is entirely filled with rock material, the crusher is said to be choke fed, and this is the preferred way to operate a cone crusher Readings were taken during normal operation of the crusher, ie choke fed conditions2023年5月29日 The ® HP Series™ cone crusher product family includes altogether nine models HP100 HP200 HP300 HP400 HP500 HP900 HP3 HP4 HP5 HP6 HP Series cone crushers provide predictable and consistent capacity, end product size, gradation and shape, making them a safe choice for aggregates and mining HP Series cone crushers – High performance Cone crushers Cone crushers are one of the main choices for secondary crushing A cone crusher is a powerful machine that is used in largescale industries for crushing various types of materials into smaller sizes It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and forceTypes of Crushers: What You Need to Know Machinery

Cone crusher performance evaluation using DEM simulations

2017年4月1日 The laboratory crusher is a Morgårdshammar B90 cone crusher that has been equipped with custom machined liners, variable speed drive and a National Instruments data acquisition system The results provide novel insight regarding the stochastic flow behaviour of particles when exited by the mantle at high frequencyKnown for high capacity, superior endproduct quality and energy efficiency, ® HP6™ cone crusher consumes up to 20% less energy than other cone crushers of the same size Optimized performance ® HP6™ cone crusher 2009年10月1日 Analysis and modeling of cone crusher output The operational part of the cone crusher is the crushing chamber, which consists of a mantle and a concave liner As shown in Fig 1, the axis of the mantle intersects the axis of the crushing chamber at point O, which is the pivot point The angle between the two axes is γ, which is the eccentric Analysis and optimization of cone crusher performance

CYBASi Cones High Performance Cone Crusher

2022年7月6日 Cone Crusher High Performance Cone Crusher SINCE 1946: Our journey started here with the introduction of the Andreas Impact Crusher and the beginning of ; now backed by a reference list well exceeding 75,000 machines Our customers benefit from an extensive range of services, realized in our industry knowledge,Crusher Performance Map is achieved, which in turn can be used when optimizing a given crushing task or a crushing plant Keywords: aggregates, comminution, crushing, mining, modelling,CONE ResearchGate2020年6月3日 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries Inside the crusher, a piece of steel, known as the mantle, rotates eccentricallyA Detailed Overview of Cone Crushers and What You Need

Influence of Two Mass Variables on Inertia Cone Crusher Performance

2021年2月4日 Inertia cone crushers are widely used in complex ore mineral processing The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher Particularly the operative crushing force of the moving cone and the amplitude of the fixed cone are affected, and thus the energy Specialized in the design, manufacture and supply of highquality mining machines, wear parts, and engineering parts for the mining and quarrying Industries +86 0579 market@wjmachineCone Crusher Parts, Ball Cap, Bowl Liner WUJING MACHINE