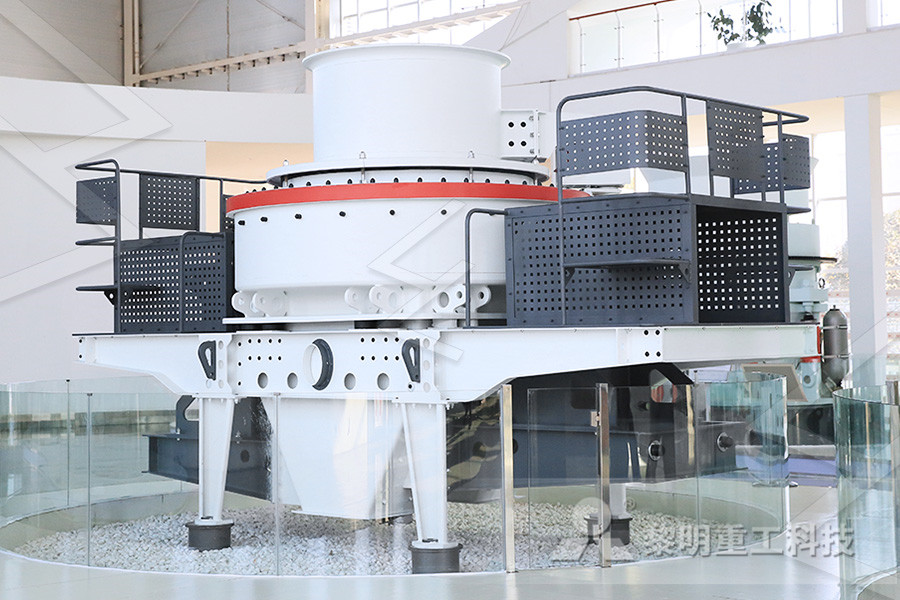

Powder Crushing Plant To Process Mineral Materials

2019-07-15T07:07:27+00:00

Review on advances in mineral processing technologies

2022年4月1日 The first comminution stage in a mineral processing plant is crushing, which reduces the size of particles from up to 1 m down to 05 cm (depending on the type of milling circuit) Crushing is typically a dry process that makes use of Gyratory, Jaw, and Cone 2023年6月7日 The purpose of mineral processing is to treat the nonstandard, unsorted, and lowgrade complex paragenic minerals into wellsorted concentrates that meet the Mineral Processing SpringerLink2023年1月19日 River stone crushing plant is the major crushing unit to process river stones like cobble rocks, pebble, sand gravel, silica etc It calls for crushing, screening Mineral Processing Plant, Aggregate Plant, Mineral Ore Plant

11192 Crushed Stone Processing and Pulverized

2021年6月25日 Due to the specialized characteristics of the mineral products and the markets for these products, pulverized mineral processing plants have production rates Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in Mineral Processing an overview ScienceDirect Topics2020年2月13日 Coarse comminution testwork and modeling are powerful tools in the design and optimization of mineral processing plants and provide information on energy consumption Additional information on mineral Understanding Mineral Liberation during Crushing

(PDF) Optimization Capabilities for Crushing Plants

2022年4月26日 This thesis presents a multilayered modular framework for the development of the optimization capabilities in a crushing plant aimed at achieving 2022年9月1日 The objective is to provide an overview and some selected examples of potential methods for energyefficient production of valuable materials from complex Towards waterless operations from mine to mill ScienceDirect2019年1月1日 Main properties of the processes of iron ore destruction in terms of its simultaneous effect by mechanical load and electric field of ultrahigh frequency have been studied(PDF) Research into the crushing and grinding

The production of pig iron from crushing plant waste using hot

2018年3月1日 The process was started by washing process and magnetic separation of raw material as an effort to improve iron content degree from crushing plant waste The next process was preparing the composite pellet with the particle size of −80 + 100 mesh and with the composition of 80% iron ore, 15% wood charcoal, and 5% bentonite2021年6月10日 According to one estimate, the mining industry consumes 12EJ per year of energy – or 35% of total final global energy consumption1 The energy intensity of mining is also predicted to increase over time as deposits that are lower quality, deeper and more difficult to extract are minedCrushing Energy Efficiency North American Mining Magazine2023年8月20日 More About Crushers August 20, 2023 Crushers are used to break up large pieces of rock and bulk materials The size of the eventual pieces depends largely on the type of crusher unit used; some models are designed to merely break large stones into manageable segments, while others are engineered to reduce an entire workpiece to dustMore About Crushers Thomasnet

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 crushing plants to a model specially designed for integration into roadtransportable put rates when crushing mediumhard and hard materials Singletoggle jaw crushers are characterized by a high throughput rate, simple design, low weight and Serrated jaw plates enhance the crushing process When the 200 250 300 350 400 The mill feed ore is sampled after a continuous process of systematic mixing, crushing, grinding, and pulverizing in the beneficiation plant The fragment sizes have attained a best possible interlining homogeneity and uniformity at (−) 100 mesh size, and are collected by automatic sampler at 15/30 min intervals after ball/rod millsGrinding (Comminution) an overview ScienceDirect Topics2020年2月13日 Coarse comminution testwork and modeling are powerful tools in the design and optimization of mineral processing plants and provide information on energy consumption Additional information on mineral liberation characteristics can be used for assessing the potential of preconcentration stages or screens in the plant design In Understanding Mineral Liberation during Crushing Using

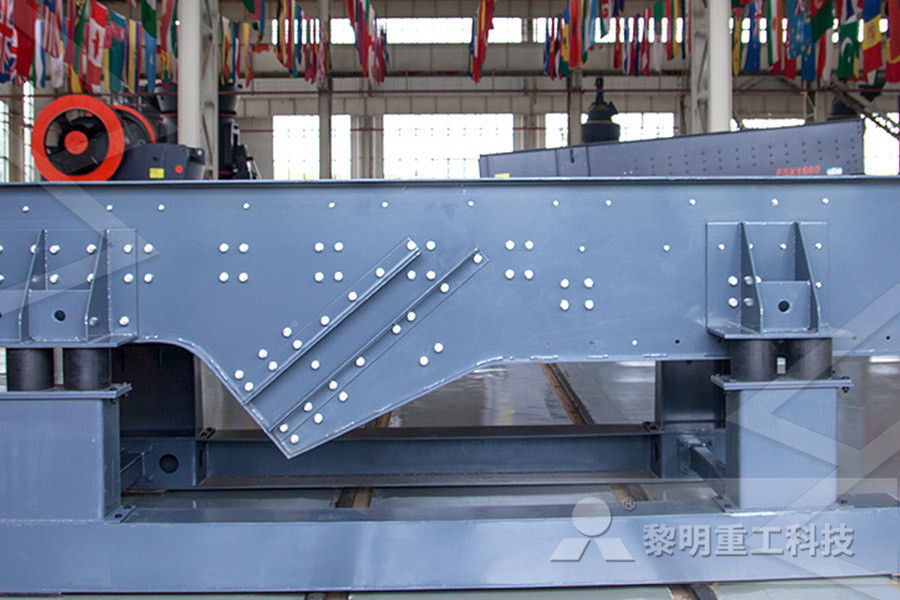

Improving yield and shape in a crushing plant ScienceDirect

2009年6月1日 This paper aims to show how process optimisation can be used in a scale quarry in order to optimise yield and product quality for a wide range of aggregate sizes Simulations and optimisation results are verified with measured data from a crushing plant A major advantage of the cone crusher is its ability to limit the amount of waste material 2015年12月26日 Crushing in Mineral Processing crushing Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911 Metallurgist2021年8月29日 This paper concerns problems related to the mechanical processing of mineral raw materials The aspects explored were limited to the analysis of comminution technologies in terms of their effectiveness and energy consumption, modeling and simulation approaches, the assessment of crushing results, and environmental aspects Minerals Free FullText Challenges in Raw Material

1125 Clay Processing US EPA

2015年9月10日 11251 Process Description14 Clay is defined as a natural, earthy, finegrained material, largely of a group of crystalline hydrous silicate minerals known as clay minerals Clay minerals are composed mainly of silica, alumina, and water, but they may also contain appreciable quantities of iron, alkalies, and alkaline earths2023年3月16日 The process of crushing copper ore typically involves a series of steps Here is a general outline of the process: Mining: Copper ore is typically mined from an openpit mine or underground mine What is the process of crushing copper ore? LinkedIn2007年2月1日 The use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust Remedies to this problem include the retrofitting of shrouds, enclosures, local exhaust ventilation (LEV) systems and water suppression systems The single or combined application of these Improved dust capture methods for crushing plant

Advances in dewatering and drying in mineral processing

2021年4月13日 Abstract In mineral processing, dewatering and drying are critical aspects from the technical and economical viewpoints These operations should be considered carefully to achieve optimal water 2022年1月23日 31 Introduction to Crushing and Grinding of Bauxite The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the processPhysical Bauxite Processing: Crushing and Grinding of Bauxite2021年8月25日 The development in the dynamic process simulation for crushing plants [1,23] provides opportunities to integrate equipment models into the continuous process performance estimations Integration of calibration methodologies for the dynamic process models to the digital data collection system such as mass flow and power draw can be a Minerals Free FullText Applied Calibration and Validation

Mineral processing Metallurgy, Crushing Grinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect TopicsThis study focussed on flowsheet simulation for mineralogicalbased approach to geometallurgy of iron ores Process unit models used were selected based on their applicability at particle level for iron ore beneficiation and flowsheet simulation The feed streams for plant simulation were runofmine feed and forecast feed from ore textural Process simulations in mineralogybased geometallurgy of

Concrete aggregates properties crushed by jaw and impact secondary crushing

2019年1月1日 A twocrushing process can be found in European recycling plants, while the choice of a secondary crusher often relies on qualitative criteria such as coarse and fine RCA recovery fractions However, a body of mineral processing literature supports the concept that comminution type might change the properties of the products attained