Eccentric Shaft Of Roll Mining Mill Machine

2019-07-21T05:07:33+00:00

Design and optimization of eccentric shaft of pilger

2018年1月21日 geometry of the eccentric shaft Out of two modifications proposed to improve the fatigue life of eccentric shaft, the uniform diameter eccentric shaft yielding 2019年5月24日 eccentric shaft Operating data Speed of eccentric shaft n = 1,800 min –1; radial load F r = 238 kN; number of bearings z = 4; required nominal rating life L h The Design of Rolling Bearing Mountings Schaeffler 180° eccentric shaft peg rotation Rotating the eccentric shaft through its second quadrant (90–180°) causes the planetary gear to roll anticlockwise inside the annular gear so that Eccentric Shaft an overview ScienceDirect Topics

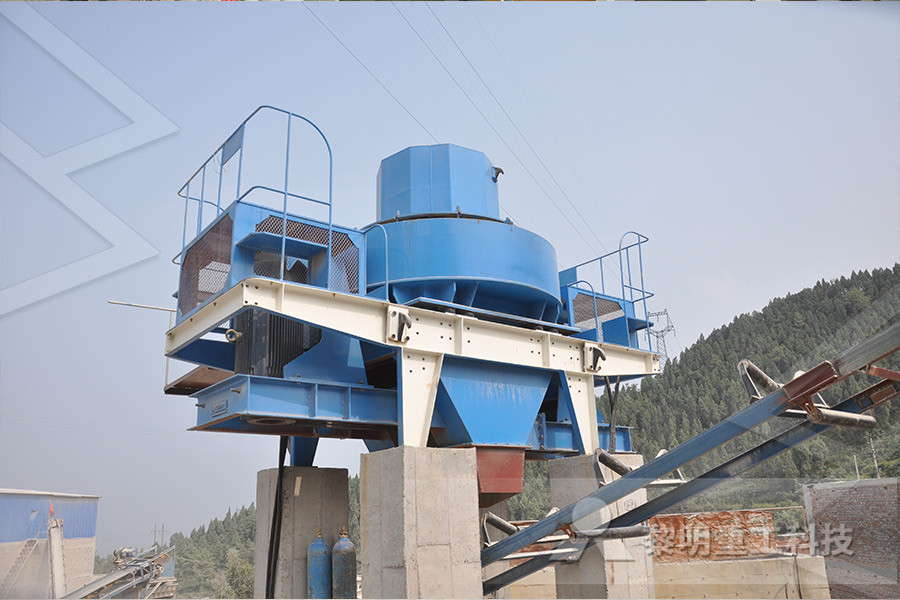

Eccentric Roll Crusher ERC®

The Eccentric Roll Crusher ERC® is the result of rich expertise in mining equipment and industrial machinery Its lowwear design and durable components enhance efficiency in 2011年6月1日 Abstract A new concept for forming eccentric shafts on the basis of the crosswedge rolling (CWR) process was presented This concept was based on the CrossWedge Rolling of Shafts With an Eccentric Step2019年8月24日 Eccentric shaft bearings The Eccentric shaft carries four bearings Two of these bearings are situated at the crusher frame, supporting the shaft while the other two Design and Construction of Rock Crushing Machine from

Mining Technologies Eccentric roll crushers ERC

2020年8月21日 Eccentric roll crushers ERC® Mining Technologies 1 A B D E C 2 3 4 5 6 7 8 9 10 10 9 3 5 A B D E C Crushing hard rock in mines and quarries, no matter if in Figure 113 Schematic of roll crushers for coal breakage (A) Singleroll crusher; (B) doubleroll crusher Singleroll crushers may be either feederbreakers, or conventional rolls The Roll Crusher an overview ScienceDirect TopicsQuality mining crusher eccentric shaft find quality shaft, Steel Pipes shaft from Jiyuan Zhongyuan Special Steel Machine Manufacture Co, Ltd of China Suppliers mining crusher eccentric shaft of shaft from China Suppliers

What Are Jaw Crushers and How Do They Work?

2019年3月28日 The eccentric in a doubletoggle jaw crusher is found behind the swinging jaw, while the eccentric on the singletoggle is located at the top Conclusion Jaw crushers are essential equipments in all 2018年8月7日 14 Shaft / pulley key 2 Cutting and Milling Machine table 1 Marking out, Cutting, Assembly and Welding Assembly simply means the putting together of parts to make a(PDF) Design and Construction of Rock Crushing Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediaterange sizereducing machines A schematic diagram of a cone crusher is shown in Fig 46 AThe drive is similar to that of a gyratory crusher The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the Cone Crusher an overview ScienceDirect Topics

Construction, Working and Maintenance of Crushers for

2018年12月26日 actuating mechanism (eccentric and driving gears), and in its upper part a cone shaped crushing chamber, lined with wear resisting plates (concaves) Construction detail and working of the crusher is as under The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assembly2023年9月27日 Description Jaw Crusher Eccentric Shaft is installed on the top of the jaw crusher It runs through the movable jaw, pulley and flywheel All of them are connect with each other by the eccentric shaft The rotation of eccentric shaft causes a compressive action of the moving jaw Jaw crusher eccentric shaft is constructed with large Jaw Crusher Eccentric Shaft Crusher Spare Parts GTEK GTEK MINING2019年4月1日 After the detailed design of this roll crusher, a prototype of the machine was built and extensively fieldtested in a sixmonth campaign at a hard rock quarry in Germany The crusher model ERC 2525 selected for this purpose has a crushing roll of 2500mm in diameter and width The feed opening to the crushing chamber is 2500mm wide and An eccentric solution to the primary crushing concept Quarry

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The objective of this report is to provide the details of size reduction methods involved in mineral processing using crushing equipments Crushing is the first step of mineral processing where The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:AMIT 135: Lesson 5 Crushing – Mining Mill Operator TrainingThe wide variety of ways our customers are already using the machine shows just how helpful the technology is Our HPGR is a perfect complementary tool to work in conjunction with, and even enhance the performance of traditional grinding mills and fixedgap crushers The HPGR exposes feed material to very high pressure for a short amount of timeHigh Pressure Grinding Roll for advanced crushing

Ball Mill Working Principle And Main Parts

2015年7月14日 The main part of the ball mill mainly include feeding part, discharging part, a rotary part, a transmission part (reducer, small gear, motors, electrical control) and other parts Hollow shaft adopts steel 2018年1月21日 The eccentric shaft of the pilger mill was modeled using UNI GRAPHICS NX 75 The eccentric shaft was discredited using dominant elements The 3D CAD model was imported into ANSYS CLASSICAL 110 in PARASOLID format; here the eccentric shaft was meshed using 3D solid elements using mapped mesh technique Sub assembly of Design and optimization of eccentric shaft of pilger Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw A double toggle crusher has, basically, two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other Primary Crusher an overview ScienceDirect Topics

Roll Crushers Williams Crusher

A roll crusher is a type of crushing equipment used to reduce the size of materials Size reduction is accomplished by compressing feed material between two cylindrical rollers that rotate in opposite directions Before crushing, the material feeds into the gap between the rollers As the rollers rotate, the material is compressed and reduced HGPR Pro enables improved productivity, reliability, and product quality, at lower cost This cuttingedge machine also comes with advanced digital functionality that enables continued process optimization and predictive maintenance These benefits are available whatever your grinding needs Whether it’s a new machine or upgrade, for an HPGR Pro High Pressure Grinding Roll Rotating Body: it is composed of moving jaw, eccentric shaft, bearings, pulleys and other parts, We are presenting Hammer Mill Machine from our impressive gamut of Industrial Crushers These are used for wet and dry crushing operations involving brittle or semi hard materials in mining, cement, and other industries The Roll Crusher is Industrial Crushers Single Toggle Jaw Crusher

Eccentric Shaft JAW CRUSHER Crusher Mills, Cone Crusher,

Eccentric Shaft – Construction Crushers Training and Back Figure 456 Support shaft, removal and installation Up TM53820233121 Crusher Jaw Diesel Engine Driven Semitrailer Mounted 35 ton per hour Capacity European jaw crusher for sale,mobile jaw crusher 50 ton per Heightened movable jaw assembly lengthens life of JC jaw crushersMovable jaw assembly, Eccentric Shaft Rotation Speed (rpm) 320: 330: 330: 250:Jaw Crusher+eccentric Shaft+assembly Crusher Mills, Cone is a world leader in roller press technology having supplied several machines over the last 30 years Our roller press family is split into two product lines, each uniquely designed to best serve their respective industry: § Hydraulic Roll Press (HRP) for Cement applications § High Pressure Grinding Roll (HPGR) for Mining applicationsRoller press HPGR technology solutions

Mining Technologies Eccentric roll crushers ERC

2020年8月21日 drive to the eccentric shaft of the roll This is generating the oscillating motion of the freely rotatable roll with constant large stroke in the entire crushing cavity Consequently, the crushing gap between the roll and the jaw in the crusher housing changes constantly and the feed material which has not been screened out is