Ball Mill Cataracting Medium

2020-07-20T09:07:05+00:00

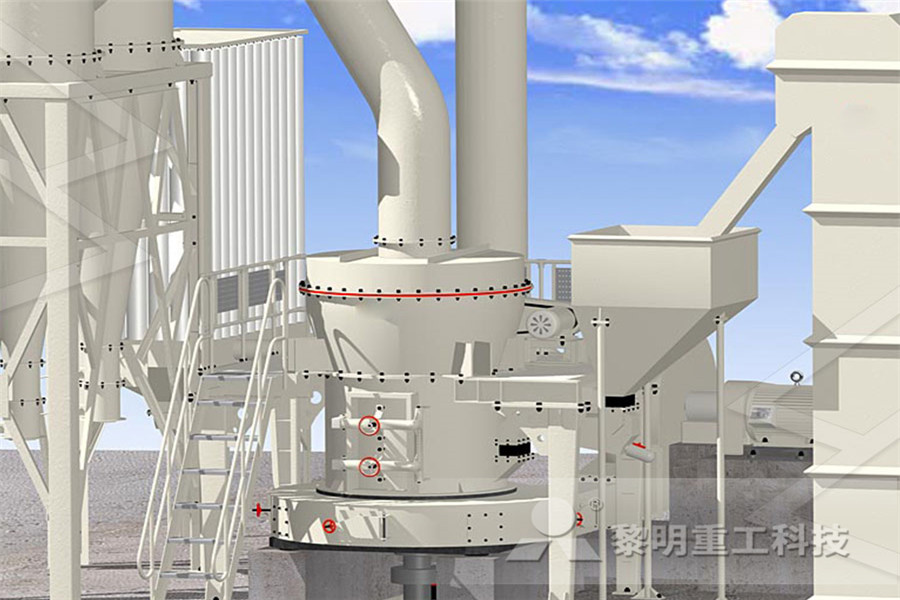

TUMBLING MILL MECHANICS Springer

2017年8月29日 There are two kinds of grinding body movements: either they describe an approximately parabolic trajectory, and knock against the material bed in a process known as cataracting; otherwise they slide and roll downwards on the material bed surface, this 2013年12月30日 speed continuing to increase, cataracting movement is more obvious, and drop points of steel balls moved up and the impact velocity of steel balls is also faster The Simulation and Analysis on Medium Motion in Ball Examples of movement of the media inside a ball mill simulated using DEM: centrifuge (left), cataract (middle) and cascade (right)Examples of movement of the media inside a ball

Geometric features of tumbling mill flows: A positron

2019年10月12日 1 Introduction Industrial tumbling mills typically operate in the high Froude range (cascading or cataracting) and exhibit a rich coexistence of flow regimes ( Abstract An experimental and numerical study on the grinding media dynamics inside a baffled ball mill under different solidflow regimes, namely, cascading, cataracting, and Experimental and Numerical Study of Grinding Media Flow in a Ball Mill 2020年10月22日 Abstract Ball mill is the widely used comminution device for the size reduction of iron ore particles, yet the underlying mechan isms of heat transfer and Advances in Mechanical Engineering 2021, Vol 13(3) 1–9

Trajectories and impact velocities of grinding bodies in planetary ball

This contribution presents such a theory of the cataracting motion of grinding bodies in a planetary ball mill An analytical method for the evaluation of trajectories is given which The required speed of the ball mill with grinding media with innovative lifters at cataract mode of operation for the three types of materials is almost the same with an average value of3: Mode of operation of a ball mill Download 2023年6月27日 this paper, the method was used to study the collisions between grinding media and grinding media and walls in ball mills, which is the most used unit operation in Experimental study of clinker grinding in a ball mill and

Effects of Ball Size Distribution and Mill Speed and Their Interactions

2020年7月2日 The small balls move to the outer layer of the ball charge and interrupt the contact of big balls with the mill liners and lifters and preventing them from rising and their presence in the cataracting regime and this is exacerbated when the small ball fraction increase The big balls mostly appear in the cascading flow region, and then more Mill liners need to protect the mill shell from damages due to wear and transmit the energy from the rotating mill to the ball charge They can be classified either as impact/cataracting for very coarse to coarse grinding, Mining MagotteauxThere are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high density Steel and other metal balls are the most frequently used grinding media with sizes of the balls ranging from 10 to 150 mm in diameter [30]Grinding in Ball Mills: Modeling and Process Control

3: Mode of operation of a ball mill Download Scientific

The required speed of the ball mill with grinding media with innovative lifters at cataract mode of operation for the three types of materials is almost the same with an average value of 45% of CS2022年4月4日 Selection of ball mills is discussed in Highenergy and lowenergy ball millschapter [1, p48–49] Figure 2 Main factors that affect the endproduct and its properties during ball milling [1, p48–49] (Figure: Aki Saarnio) Shape of the milling vial Internal shape of the ball mill can be flatended or concaveended (roundended)Ball milling as a synthesis method Aalto University Wiki2019年10月12日 Industrial tumbling mills typically operate in the high Froude range (cascading or cataracting) and exhibit a rich coexistence of flow regimes (Mellmann, 2001) that are bounded by nonlinear surfaces as illustrated in Fig 1 1 The “rising enmasse” region is dense and follows closely the rotation of the drumFlowing atop the rising en Geometric features of tumbling mill flows: A positron

AG/SAG mill acoustic emissions characterisation under different

2021年9月1日 The presence of steels balls (grinding media) promoted a rapid rock reduction process, particularly by impact breakage where higher kinetic energies (high specific gravity) are produced by most cataracting or falling balls in the mill Download : Download highres image (541KB) Download : Download fullsize image; Fig 21999年9月1日 Due to the complexity of charge motion inside a ball mill, it is very difficult to calculate some mean shear rate accurately Klimpel (1984) estimated the shear rates to range from 0 to 60 s −1, but no evidence was given as to how this figure was calculated Mishra (1991) and Mishra and Rajamani, 1994a, Mishra and Rajamani, 1994b used the Estimation of shear rates inside a ball mill ScienceDirect2023年9月18日 a ball mill by dimensional analysis Martin Giraud, Cendrine Gatumel, Stéphane Vaudez, Jeremy Nos, Thierry equipment: slipping, cascading and cataracting, which are themselves divided into seven subregimes [8] The slipping motion is embedding the grinding media in the dimensional analysis of the ball mill would be of Investigating grinding mechanisms and scaling criteria in

How Ball Mills Lifter Bar Affects Charge Motion 911

2018年8月8日 There are two wellknown modes in which the ball charge moves inside the mill: cascading and cataracting The cascading motion of ball charge forms a compressive zone inside the mill where particles may break under slow compression The cataracting motion, on the other hand, causes the particles to break under highimpact forces It has He shows that Kick's law is reasonably accurate in the crushing range above about 1 cm in diameter; Bond's theory applies reasonably in the range of conventional rodmill and ballmill grinding Examples of movement of the media inside a ball 2013年12月30日 speed continuing to increase, cataracting movement is more obvious, and drop points of steel balls moved up and the impact velocity of steel balls is also faster Keywords: Ball Mill; Discrete Element Method; Movement of Single Diameter of Steel BallsThe Simulation and Analysis on Medium Motion in Ball

PHYSICOCHEMICAL PROBLEMS OF MINERAL

in mill fillings of 15, 20, 25, 30, 35 and 40% with ball media of 2 and 25 cm in diameter For every mill filling, the the mill transited to the cataracting and impact breakage was the main 2017年7月1日 When the mill charge contained monosized balls, the ball flow regime inside the mill transited to the cataracting and impact breakage was the main breakage mechanism(PDF) The effect of ball size distribution on power draw2021年7月27日 media shape and mill power The objective of this dissertation was to investigate how media shape affects grinding Ball size distribution inside an industrial mill was analysed in terms of shapes and sizes Load behaviour, mill power and breakage as affected by media shapes were studied in a pilot laboratory mill An inductive proximity EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

Experimental study of clinker grinding in a ball mill and the

2022年8月18日 Discrete Element Methods (DEM) is a numerical tool consolidated to the simulations of collisions in particulate systems In this paper, the method was used to study the collisions between grinding media and grinding media and walls in ball mills, which is the most used unit operation in clinker grinding, the majority component of the cement 1998年1月1日 In other words, since both the mills operate under similar conditions, it is clear from Figure 6 that the cascading mill utilizes a larger fraction of energy for grinding than the conventional ball mill w t O U t O m 0 L m 01 001 001 01 I o~ New Mill Ball Mill Relative slze [] Fig6 A comparison of the feed size breakage distribution Cascading mill: A phenomenological design for improved 1999年8月3日 Rose and Sullivan showed critical rotation speed Nc, to reach the final stage, ie, centrifugal motion: N c = 1 2π 2g D−2r where D is the inner diameter of a jar and r is the radius of balls All throughout, they used the critical rotation speed as the constant value for given conditions of ballmill [5] After this work, the critical Critical rotation speed for ballmilling ScienceDirect

(PDF) Process Engineering with Planetary Ball Mills

2013年2月7日 Scheme of a ball motion pattern in a single pot of a planetary ball mill – (a) cascading, (b) cataracting, (c) rolling Media Mills’’ in 1996 Afterwards he worked as a general manager1 Ball Mill Ball mill merupakan salah satu jenis unit grinding, ball mill bekerja dengan prinsip impact, ball mill menggunakan bola besi sebagai grinding medium Gaya yang bekerja pada sebuah ball mill yaitu gaya gesek, tumbukan dan gravitasi PengecilanAnalisis Perbandingan Antara Kondisi Normal Dengan