Ball Mill Production Line Aluminium Dross

2023-08-09T00:08:15+00:00

Aluminum Recovery from White Aluminum Dross by a

2021年6月2日 The aluminum recovery from white aluminum dross by a mechanical treatment and sizing followed by remelting process was investigated The dross was Aluminum Dross Ball Mill Gravity ball crushing technology is adopted in the ball milling part of ball mill ash screening machine system The cold ash can be crushed by the weight of We are manufacturer of aluminum ingot/billet production line2018年3月25日 In one study, from an alkaline leaching solution, aluminum hydroxide was recovered by precipitation with NH 4 HCO 3 and Processes Free FullText Ball Milling Treatment

Studies on the Formation and Processing of

2021年7月12日 Advanced processes, which have been introduced into the processing of aluminium dross in recent years, are based on plasma technology The aim here is to expose the metallic aluminium trapped in 2023年8月19日 Cold aluminium dross ball machine is designed as hightech machine based on aluminium dross composition and nature, which Cold aluminium dross ball mill and sieving machineHenan Hehong Machinery is an enterprise engaged in ball mills, rod mills, ball presses, aluminum ash equipment, steel slag equipment, mineral processing equipment, and Ball Mill, Rod Mill, Ball Press, Aluminum Ash Equipment

China Aluminium Dross Separating Machine/Accessory

Specializing in the production of aluminum(zinc) dross separator, automatic aluminium dross recycling line, casting equipments Our products, Hot dross recycling production line, 2022年9月22日 Mill scale and aluminum dross are the industrial wastes from steel and aluminum industries, which have high concentrations of Fe 2 O 3 and Al 2 O 3, Metals Free FullText Synthesis of Ferroalloys via Mill ScaleDross 2023年7月28日 China Aluminum Machinery Manufacturer Trading Combo, Offer Total Solutions For Your Aluminium Project In Chips Melting, Aluminum Dross Processing, Cold aluminium dross ball mill and sieving system –

/ aluminum recovery from dross using ball millsmd

You've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity2020年7月2日 It can be generally recovered by screening, gravity concentration, rotary furnace method or electrical concentration method 1 Screening After cooling, the heattreated aluminum dross that is Aluminum dross hot and cold treatment recovery Aluminum Dross ball mill Introduction: and the ball mill is widely used in powdermaking production line including cement, silicate, aluminium dross grinding mill – pakistan crusher,stone ball mill for aluminium dross Mining Quarry Plant

Aluminium dross/soda lime glass wastederived high

2021年12月3日 planetary ball mill (weight ratio of glass:zirconia balls ¼ 1:2) at 350 rpm for 90 min The milled glass powder was subsequently sifted through a 50mesh sieve Three batch compositions (GF25e75) were manufactured from waste glass powders and aluminium dross foaming agents according to thenominalcompositions 2023年3月1日 Aluminium dross, composed of oxides, salts, and aluminium, is a useful waste of the aluminium industries Dross comes from primary and secondary aluminium smelter units Primary dross contains high metallic values as compared to secondary dross Dross is considered hazardous waste due to its toxicity and leaching characteristicsOn trending technologies of aluminium dross recycling: A 2014年9月16日 We have plants which produce between 100 – 1000 MT/day both primary and secondary Yes, our dross processing machine can be suitable for aluminum remelt facilities Also we can offer ball mill and aluminium dross sieving machine for cold aluminum dross If you can give us the processing quantity per day, we can make the project FAQS about aluminium dross processing and dross recycling

ball mill production line of aluminum dross

ball mill production line of aluminum dross T19:09:40+00:00; Cold aluminium dross ball mill and sieving machine The high efficiency and low maintenance rate of the ball mill will guarantee the long stable running of aluminium dross production line; it can bring more profit to the factory The main function of aluminium dross sieving machine is Our products, Hot dross recycling production line, prevents high temperature aluminium dorss from burning loss or oxidation: Cooled to normal temperature within 1015 miniutes Aluminium recovery is ove 90%, reduces labor, realizes Mechanical operation, centralized dust treatment and improved workshop environmentChina Aluminium Dross Separating Machine/Accessory 2015年9月10日 An example of mechanical cleaning is the dry milling process Cold aluminumladen dross and other residues are processed by milling and screening to obtain a product containing at least 60 to 70 percent aluminum Ball, rod, or hammer mills can be used to reduce oxides and nonmetallic particles to fine powders for ease of removal AP42, CH 128: Secondary Aluminum Operations US EPA

Ball Mill Production Line Of Aluminum Dross A

2019年10月24日 Ball Mill Production Line Of Aluminum Dross Aluminum dross ball mill production capacity065615t/h discharge size0074089mm ball loading weight15338t applicationit can process aluminum ore, aluminum dross and other materials, and it plays an important role in building materials, metallurgy, electric power اقرأ أكثرOur product range includes a wide range of Endless Rubber Conveyor Belt, Aluminium Dross Pulverizer Machine, Aluminium Dross Ball Mill, Metal Screening Machine and Jaw Crusher Endless Rubber Conveyor Belt Rs 25 Lakhs/ Unit Aluminium Dross Pulverizer Machine Rs 15 Lakhs/ PieceAluminium Dross Processing Plant Aluminium Dross 2021年2月8日 Here’s what No One tells you about Comprehensive Utilization Of Aluminum Dross China electrolytic aluminum industry is developing rapidly, and its output level has been leading the world for Here's what No One tells you about

Aluminium dross/soda lime glass wastederived highquality

2021年11月1日 Three batch compositions (GF25–75) were manufactured from waste glass powders and aluminium dross foaming agents according to the nominal compositions displayed in Table 2 These batches were dryblended in a planetary ball mill for 30 min, then drymolded in stainless steel moulds (10ⅹ10ⅹ10 cm 3, interior surface coated with 2023年4月3日 facility A schematic diagram of primary aluminum production is shown in Figure 1211 12121 Bayer Process Description In the Bayer process, crude bauxite ore is dried, ground in ball mills, and mixed with a preheated spent leaching solution of sodium hydroxide (NaOH) Lime (CaO) is added to control phosphorus content121 Primary Aluminum Production US Environmental 2023年10月3日 1 2 3 Aluminium dross processing, cooling, ball mill, sieving, magnetic separator, pulverizer aluminium dross recovery machine, aluminium dross processing machine, aluminium dross separating machine, aluminum dross processing, aluminium dross cooling machine, molten aluminium degassing and refining machine, molten Aluminium Dross Processing │ Aluminum Equipment Total

(PDF) Synthesis of Ferroalloys via Mill ScaleDrossGraphite

2022年11月7日 These results provide evidence for carbothermic reduction of the Fe2O3Al2O3SiO2 system at 1550 °C and show the novel method to upcycling aluminum dross and mill scale toward a circular economy2020年12月20日 Secondary aluminum dross is regarded as a hazardous solid waste in many countries A coupled life cycle assessment and life cycle costing method was used to evaluate the environmental impact and economic cost of two processes for producing alumina from bauxite and secondary aluminum dross The results showed that the total Life cycle environmental and economic assessment of2022年9月22日 Mill scale and aluminum dross are the industrial wastes from steel and aluminum industries, which have high concentrations of Fe2O3 and Al2O3, respectively This paper reports the conversion of reducible metal oxides in scale and dross into an alloy via carbothermic reduction at 1550 °C Scale and dross were mixed with graphite into Metals Free FullText Synthesis of Ferroalloys via Mill ScaleDross

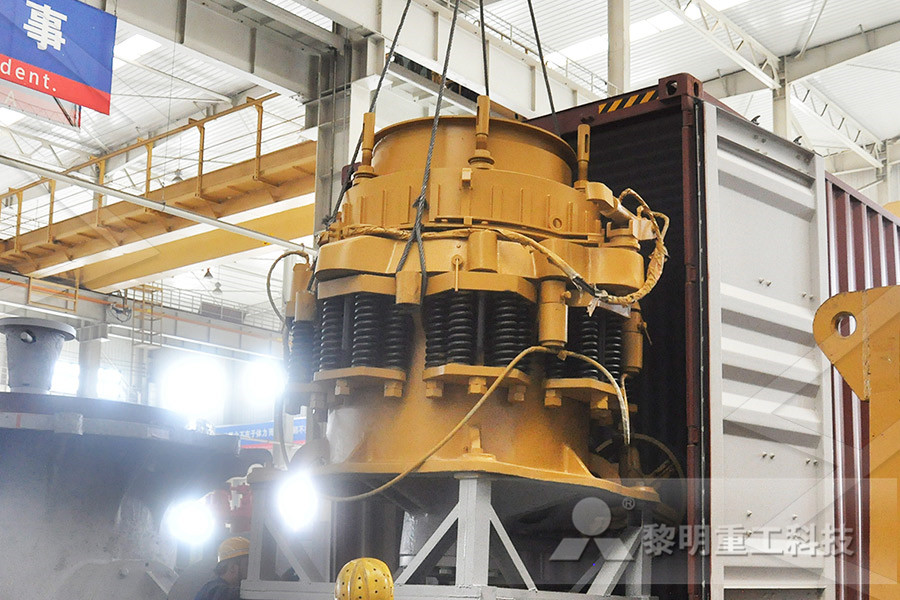

Aluminum Dross Recycling System bjhollandequip

Aluminum dross recycling system is mainly used to treat the aluminum slag generated during the smelting process The system includes aluminum dross separator, aluminum dross cooler, preliminary screening machine, ball mill, and final screening machine It can achieve the rapid recycle of aluminum dross without any fuel at furnace siteHenan Hehong Machinery is an enterprise engaged in ball mills, rod mills, ball presses, aluminum ash equipment, steel slag equipment, mineral processing equipment, and other equipment Recycle metal aluminum, Aluminum dross , Aluminum dross pressing, Aluminum slag When processing 50 tons of steel slag rod mill production line in XinjiangBall Mill, Rod Mill, Ball Press, Aluminum Ash Equipment2019年6月6日 The reactive milling time used was 5 h in a ball mill, for a ball/dross mass ratio of 65 For a molar relationship of 1:3 (Al 2 O 3 /CaO), sintered products with calcium aluminate contents of over 90% were obtained, in which tricalcium aluminate (C 3 A) was the majority compound (87%), followed by C 12 A 7 (5%)Synthesis of Calcium Aluminates from NonSaline Aluminum Dross