Technical Details Of Cone Mining Mills

2021-01-03T17:01:38+00:00

Cone Mills Schenck Process

2021年8月26日 Cone milling is a low energy size reduction concept ideal for fatty, heat sensitive, sticky, moist or other dificult to grind products It alleviates the noise, dust and heat problems associated with traditional milling techniques gentle grinding action maintains 2023年10月3日 A cone mill is a machine that is used to reduce the size of material uniformly It is named cone because of its shape and it can Cone Mills SaintyTec2014年2月28日 Cone mill is commonly used for the milling of wet and dry agglomerates in the pharmaceutical industry as it is capable of producing milled granules with desired Energybased analysis of cone milling process for the

Hanningfield I Cone Mills Hanningfield

2023年10月1日 UniMill M30B UniMill M60B The UniMill Cone Mills can be supplied with a widerange of tooling to achieve the required final 2019年12月17日 The ‘UJ’ underdriven KEK Cone Mill has revolutionised the performance of fine material and precise milling technology KEK Cone Mills offer versatile milling, coupled with low energy consumption, for KEK Cone Mill Wet Dry Milling GranulationAll Kason Cone Granulation Mill models provide gentle milling for food, pharmaceutical, powder processing and other similar applications With a range of different grinding Cone Mill Size Reducer Conical Milling for Size Reduction

Energybased analysis of cone milling process for the

2014年2月28日 Cone mill is commonly used for the milling of wet and dry agglomerates in the pharmaceutical industry as it is capable of producing milled granules with desired 2017年8月26日 INERTIATYPE CONE MILLS L~ P Zarogatskii and Yu~ R~ Neehaev UDC 66676022:62t ~ In the production of corundum, mullitecorundum, rnullite~ and Inertiatype cone mills Springer2014年2月28日 Cone mill is commonly used for the milling of wet and dry agglomerates in the pharmaceutical industry as it is capable of producing milled granules with desired Energybased analysis of cone milling process for the

Developments in iron ore comminution and classification

2015年1月1日 The Zourerat iron ore mine has two 17 m diameter × 18 m wide HPGR units treating 1400 t/h each of aerofall mill pebbles The feed is − 25 + 16 mm and has a ball mill work index of 12–14 kWh/t The iron ore has low to moderate abrasion characteristics Figure 821 shows the Zourerat iron ore flowsheet2017年3月4日 The process "Comminution" involves size reduction and sizewise classification called as screening or separation The objective of this report is to provide the details of size reduction methods (PDF) SIZE REDUCTION BY CRUSHING METHODS2015年5月13日 Abstract and Figures PhD Thesis Cone crushers are used by both the aggregate producing and the mining industry Both industries are interested in increasing the product quality while at the same (PDF) Cone Crusher Performance ResearchGate

structural erection methodology of conveyor system

\n \n TECHNICAL CALCULATION AND ESTIMATOR'S MAN HOUR, \n basis I used was a system for estimating the value of erection works of a German Company LINDE,which I completed and modified Gener ally,for elabor ation of the man hours f or er ection installation of process equipmentTANK BUILDING METHODOLOGYConventional erection method A classifying cyclone system is needed to achieve a 150 micron (100 mesh) separation The total volumetric flow rate to the system is 5000 gpm at a solids content of 5% by weight (Ï p=102) At an average relative solids density of 13, the solids mass flow rate equates to AMIT 145: Lesson 2 Classifying Cyclones – Mining Mill 2016年3月10日 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone Crushing Plant Flowsheet DesignLayout 911 Metallurgist

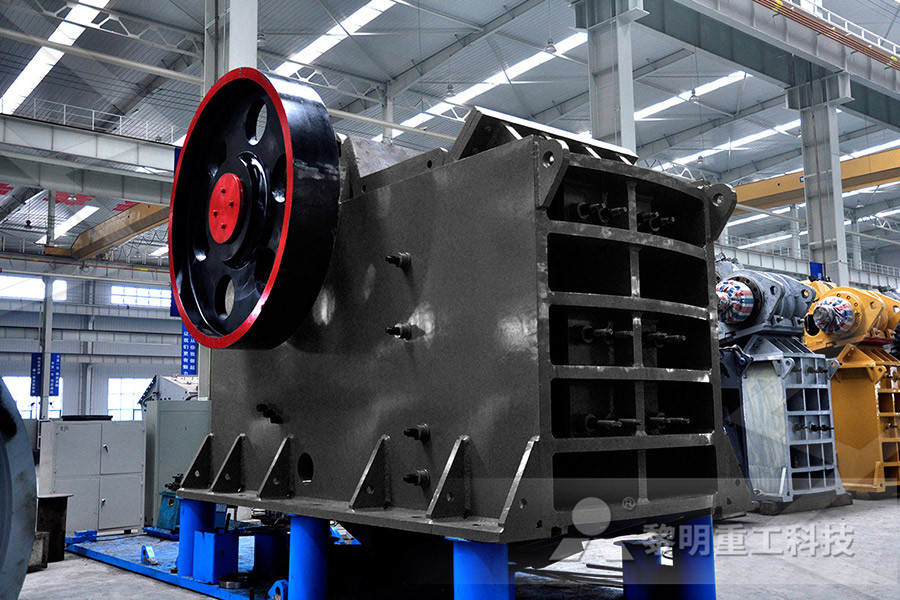

A Detailed Overview of Cone Crushers and What You Need

2020年6月3日 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries Inside the crusher, a piece of steel, known as the mantle, rotates eccentrically2023年10月4日 Cone milling is one of the most common methods of milling in the pharmaceutical, food, chemical and associated industries They are typically used for size reduction and deagglomeration or delumping of powders and granules Generally used for reducing material to a particle size as low as 180µm (80 mesh) a cone mill produces less Cone Mill Conical Milling Machine for Size Reduction2016年2月24日 stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing Crushing Plant Design and Layout Considerations 911

tc51 cone crusher technical detaols Mining Quarry Plant

2012 trio tc51 cone crusher for sale kefid Crusher in Australia Pilot Modular/kefid MC90 cone crusher; For details,Mail to sale@orecrshingplant or Live ChatCone crushers have gained such wide acceptance that they may be regarded as standard in the intermediaterange sizereducing machines A schematic diagram of a cone crusher is shown in Fig 46 AThe drive is similar to that of a gyratory crusher The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the Cone Crusher an overview ScienceDirect TopicsThe energy required to liberate a mineral of economic interest from its gangue constituents in the host rock is described in this chapter The design of equipment use for the purpose is indicated in some details Standard laboratory tests for determining this energy are described for ball and rod mills systems of grindingMineral Processing Design and Operations ScienceDirect

China Cone Mills, Cone Mills Manufacturers, Suppliers, Price

China Cone Mills manufacturers Select 2023 high quality Cone Mills products in best price from certified Chinese Steel Cone, Cone Machine suppliers, wholesalers and factory on MadeinChina Zhengzhou Hengxing Engineering Technology Co, Ltd Diamond Member Lab Cone Ball Mill for Mining Mineral Grinding Miller Ore Lab Testing US 2019年6月14日 Now, let’s get into technical details of how the conical mill works The first step of the process entails feeding the material into the cone mill through the chute There are three ways in which the material is fed They are gravityfeed, handfeed, and vacuumfeed The mode of feeding will depend on the technical specifications of your cone 8 Key Important Tips: Conical Mill Guide Senieer, Top cedar rapids jaw crusher technical manual gulin supply mining and construction equipment for mineral handling the crushing, screening, washing, grinding equipment Crushing Equiptment Technical Manual Crusher Mills, Cone

technical details hp 200 cone crusher Mining Quarry Plant

2013年4月27日 add to cart view details zg48744 used 48" telsmith model vfc cone crusher very fine cone requires 200 hp electric motor new 1972 capacity approx 70100 tph2013年3月19日 hammer mill technical data hammer mill application Leave a message, enquire about the price, solutionsTo become our quality clients will have access to a 2%10% hammer mill technical data Mining Quarry PlantGyratory Crusher,Cone Crushing Plant,Gyratory BreakerCone You can see the animation of gyratory crusher in the left grinding, service and technical solutions,excavation and sizing of rock and minerals), Ore Mineral Gyratory Crusher, Technical Data Crusher Mills, Cone

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate: