Mining Mills Roll Mining Mills

2021-02-16T12:02:14+00:00

Mining Mills AllMinings

2023年9月5日 Allminings is a company that provides mining solutions and consultancy services to support global mining efforts and give the community the opportunity to Browse 's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding Grinding mills for mining and minerals processing 2022年3月30日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO 2 emissions by up to 345 megatonnes/year, or 435% when Helping to reduce mining industry carbon emissions: A step

Mineral processing milling

2015年8月8日 Batch mills Mills which receive a discrete quantity of charge which is milled and then discharged The process is then repeated Continuous mills A mill which can 2019年10月11日 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM) For now, the HPGR has already presented in a Vertical roller mills: The new leader in grinding The roll mill is the simplest batch mixing equipment The principal design consists of two horizontal rolls, usually of equal size, arranged side by side and rotating toward each Roll Mill an overview ScienceDirect Topics

Flexible milling and grinding solutions that last

Our ATOX® coal mill has large rollers with great grinding capability of all types of coal, tolerating moisture levels up to 20 percent For the mining industry, our semiautogenous Our roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains We offer a wide range of roller mills and optional functions to match the milling solutions Roller Mills Milling GroupThe rolling mills complex was proposed to include a light and medium merchant mill with breakdown group of stands for rolling blooms into billets and an intermediate inline heat Rolling Mill an overview ScienceDirect Topics

How to choose mining ball mill and roller mill LinkedIn

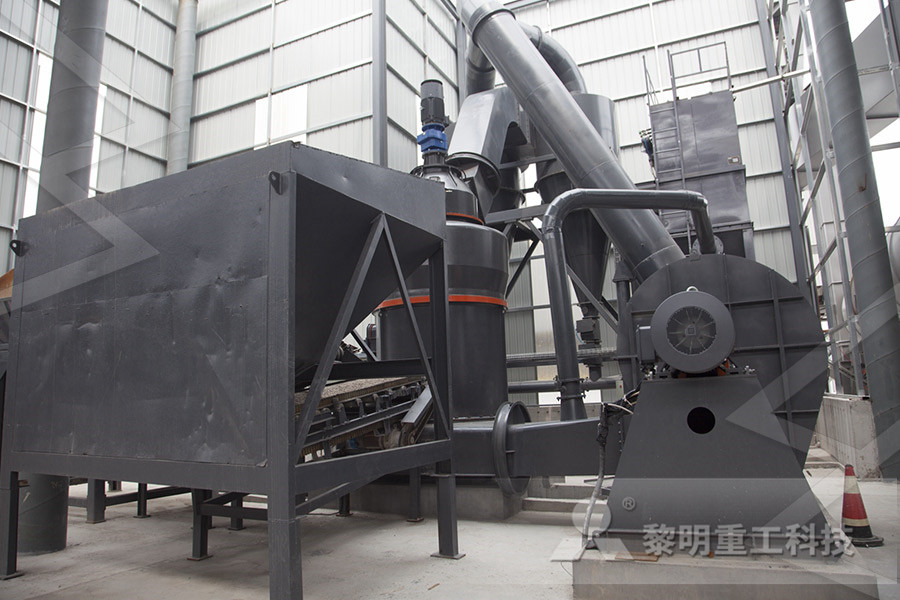

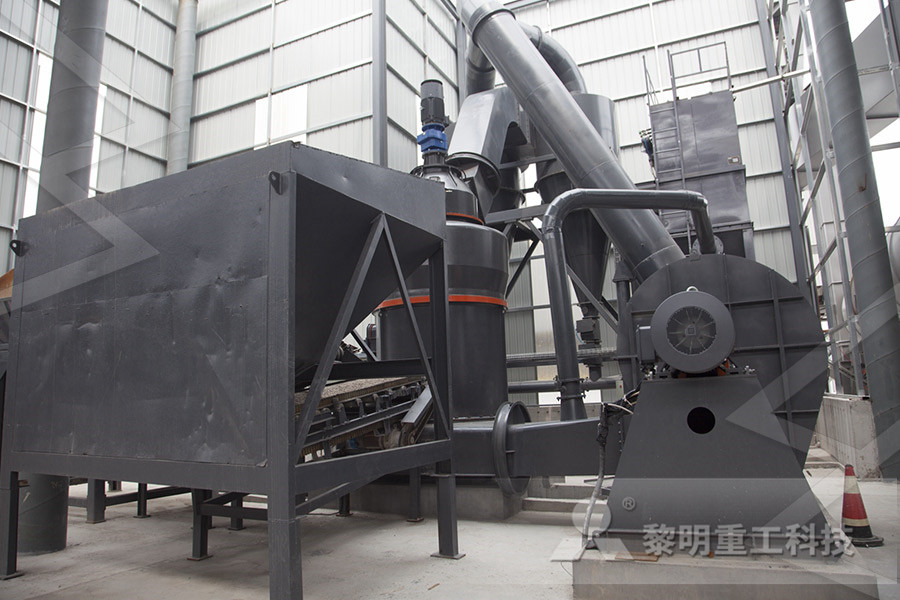

2023年4月11日 However, roller mills are more compact and have a smaller footprint, making them ideal for smaller mining operations Both ball mills and roller mills consume a considerable amount of energy AG mills are commonly used in gold and copper mines, as well as other types of mines that require the grinding of ore AG mills have a variety of applications in mining operations For example, they can be used to grind and crush large rocks and ore, preparing them for further processing They can also be used in conjunction with other types of Understanding AG Mills Basics and Their Role in Mining 2018年11月30日 Fine grinding stage: When the particle size of the product is required to be less than 05 mm, we recommended to use a ball mill (the ball mill has a feeding size of 525 mm) Rough grinding stage How to choose Rod mill and ball mill? LinkedIn

Trends in der Minenindustrie Mineral Processing

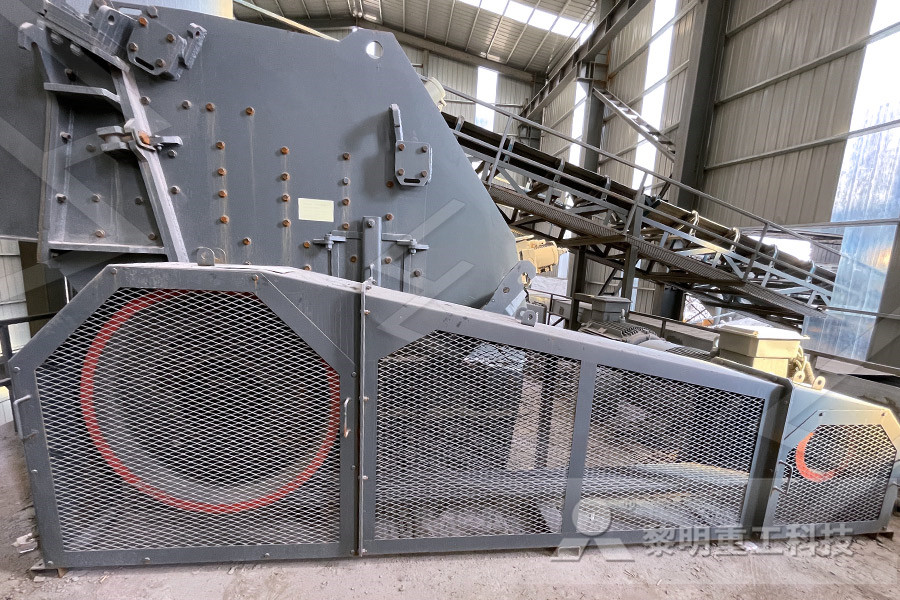

This machine boasts several new features (Fig 10) and, compared to existing HPGRs, delivers a 20 % higher throughput rate, 15%lower energy consumption and a 30 % longer lifetime of the rolls 24 Ball mills and other tube mills Ball mills as well as rod mills are widely used in the mining industry on account of their simplicity2016年4月1日 Mining mill linings are continuously exposed to wear induced by the charge, and thus, mill operation has to be interrupted on a regular basis for inspections Stoppages due to inspections and Ultrasonics for Monitoring of Mining Mill Linings: Pilot Experiments8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topics

Ball Mills Best of 2023 911 Metallurgist

2023年10月3日 Grinding Mill for Metallurgical Pilot Testing of 10 to 150 Kilo/Hr US$ 50,000 $ 40,000 Sale!The wide variety of ways our customers are already using the machine shows just how helpful the technology is Our HPGR is a perfect complementary tool to work in conjunction with, and even enhance the performance of traditional grinding mills and fixedgap crushers The HPGR exposes feed material to very high pressure for a short amount of timeHigh Pressure Grinding Roll for advanced crushing 2022年3月30日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO 2 emissions by up to 345 megatonnes/year, or 435% when compared to the established Autogenous (AG)/SemiAutogenous (SAG)/Ball mill circuit alternatives However, uptake of HPGR technology has been relatively slowHelping to reduce mining industry carbon emissions: A step

MINERAL PROCESSING MILLING United Diversity

2020年12月4日 A mill which can accept a continuous flow of feedstock and hence can operate on a continuous basis Both batch and continuous mills have their relative merits Peripheral and trunnion discharge For cylindrical mills which are continuously fed, the discharge of the final product can be either through the periphery of the mill (peripheral2009年1月1日 This paper describes the simulation of the grinding process in vertical roller mills It is based on actual experimental data obtained on a production line at the plant and from lab experiments Sampling and experiments were also carried out in a power plant that has four ballmill circuits used for coal grinding so that different equipment Grinding process within vertical roller mills: experiment and Contribute to changjiangsx/ development by creating an account on GitHub/ good performance mining roll mill crusher

Warrawoona SAG mill ready to roll MiningMonthly

2022年4月6日 THE 45megawatt semiautogenous grinding mill at Warrawoona is ready for ore commissioning, Calidus Resources has announced, with the start of milling on schedule for the end of April The Warrawoona gold project in Western Australia's Pilbara is tipped to be a robust operation with strong financial returns, based on total reserves of 2019年4月4日 Cyanide Use in Gold Mining Mining lower grade ore requires the extraction and processing of much more ore to get the same amount of gold Partially due to cyanide modern mines are much larger than before cyanide was used create vast open pits and produce huge quantities of waste More than 20 tons of mine waste are generated to used roll mining mills northdurbanswimafricaTubular Rod Mills In Mineral Processing Design and Operations (Second Edition), 2016 831 Rod Mill Charge Rod mill charges usually occupy about 45% of the internal volume of the mill A closely packed charge of single sized rods will have a porosity of 93% With a mixed charge of small and large diameter rods, the porosity of a static load could be Rod Mill an overview ScienceDirect Topics

Mineral Processing Equipment Ore Grinding Machine

2022年3月18日 Vedanta Project in South Africa 1 SAG mill, Ø85×55m 1 ball mill, Ø62×104m CITIC HIC is an experienced company specialized in designing and manufacturing mineral processing equipment, including grinding mills, crushers, vertical stirred mills, mine hoists, rotary kilns, etc2016年10月28日 In the Griffin Mill, there is a single roller suspended in a similar way to the rollers in a Huntington mill The roller is about 18 inches in diameter, and rolls on the inside of a die ring 30 inches in diameter It takes material up to 1½ inches in diameter, and crushes either wet or dry At a mine near Brad, in Transylvania, each pair Roller Mills 911 MetallurgistThe purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training