Widely Used Cement Grinding Mill

2019-05-24T08:05:22+00:00

Comparison of the overall circuit performance in the cement

2011年2月1日 Closed circuit vertical roller mill grinding In this study, a compact design and partial external recycling type vertical roller mill circuit was sampled VR mills are widely 2017年5月19日 Grinding aids are widely used to enhance mill output, improve fineness and reduce energy consumptionPerformance Overview of cement grinding: fundamentals, 2017年4月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and Operational parameters affecting the vertical roller mill

Optimization of an industrial scale open circuit three

2016年9月10日 Grate discharge single and twocompartment ball mills are widely applied types in cement grinding circuits The ball mill can have threecompartments and it can Sound pressure: 77, 96, 117 dB The TG5000 tub grinder from Vermeer is your machine for powerful processing in a convenient package, with a 540 hp (403 kW) engine and Cement mill, Cement grinding mill All industrial 2020年9月29日 Cement production process with waste utilisation areas Display full size In stage one, the essential raw materialslimestone, laterite, bauxite, kaolinite, clay, iron Full article: An overview of alternative raw materials used in cement

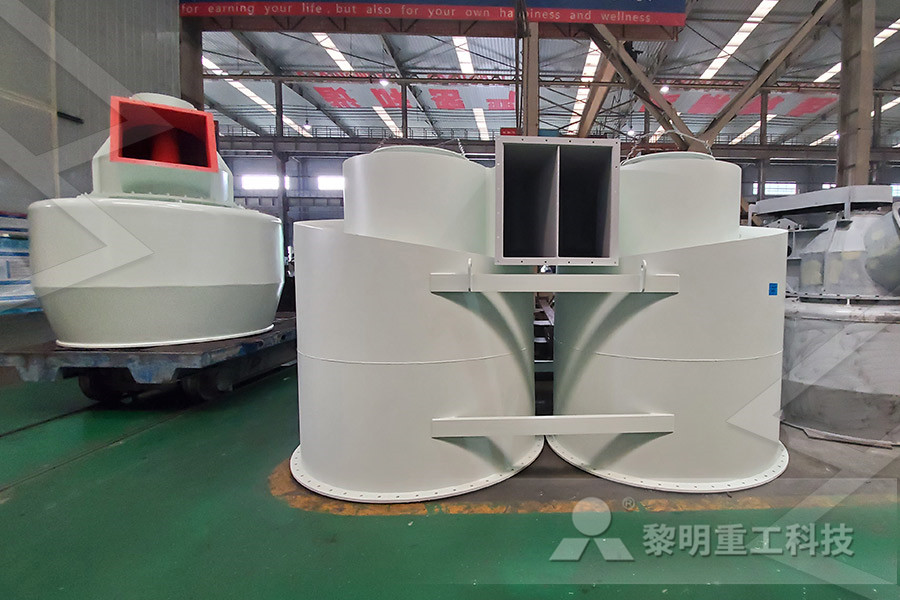

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

Cement mill also called cement grinding mill, is a cement grinding machine used in cement plant for raw materials, cement clinker, and coal grinding The cement mill produced by 2016年1月1日 PDF Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball Find, read and cite all the research (PDF) Analysis of the efficiency of the grinding 2004年11月1日 These mills combine crushing, grinding, classification and drying operations in one unit and have advantages over conventional machines and literature Cement grinding optimisation ScienceDirect

Ball Mill an overview ScienceDirect Topics

Mechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision 2013年1月1日 The most widely used cement today is Portland cement, so named because of its resemblance to the highly valued Portland Stone, found on the Isle of Portland, Dorset, UK Figure 158 18 illustrates the drying and grinding processes in a pulverising mill Download : Download fullsize image; 158 The Pulverised Fuel (PF) mill processes Coal utilisation in the cement and concrete industries2021年1月22日 In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total Based on the statistics of the electricity consumption of the raw (PDF) A Survey and Analysis on Electricity Consumption

116 Portland Cement Manufacturing US EPA

1971年8月17日 accomplished during grinding in ballandtube mills or roller mills While thermal energy for drying can be supplied by exhaust gases from separate, directfired coal, oil, or gas burners, the most efficient and widely used source of heat for drying is the hot exit gases from the pyroprocessing systemCement vertical mill, also called roller mill, is another raw mill commonly used in cement plants Compared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the modern cement industry High Grinding EfficiencyRaw Mill – Raw Mill In Cement Plant AGICO Cement Raw MillVertical roller mill for cement and slag grinding • Energy consumption: 70 % of a ball mill for cement 50 % of a ball mill for slag • Fineness: max 4 500 cm²/g for cement max 6 000 cm²/g for slag • Moisture required for stabilising the grinding bed – less influence on cement quality • Lowwearcosts • Throughput up to 300 t/hInnovation and optimisation in cement grinding INFINITY FOR CEMENT

Cement grinding optimisation ScienceDirect

2004年11月1日 Grinding occurs at the beginning and the end of the cement making process Approximately 15 tonnes of raw materials are required to produce 1 tonne of finished cement The electrical energy consumed in the cement making process is in order of 110 kWh/tonne and about 30% of which is used for the raw materials preparation and 2020年3月6日 It is widely used in clinker grinding production of cement plant and slag grinding plant CHAENG can provide various types of vertical cement mills with productivity of 50250t/h The biggest The important role of vertical roller mills in the cement industry2018年8月17日 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles Rod mills can accept feed up to approximately 50 mm (2 in) and Grinding Mills — Types, Working Principle Applications

Grinding materials processing Britannica

In cement: Grinding The clinker and the required amount of gypsum are ground to a fine powder in horizontal mills similar to those used for grinding the raw materials The material may pass straight through the mill (opencircuit grinding), or coarser material may be separated from the Read More; cutlery In cutlery: Cutlery manufactureThere are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high density Steel and other metal balls are the most frequently used grinding media with sizes of the balls ranging from 10 to 150 mm in diameter [30]Grinding in Ball Mills: Modeling and Process Control2017年10月23日 There are numerous types of grinding mills This article focuses on two widely used types: the hammer mill and the jet mill Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from millimeters to tens of microns The jet mill is primarily used for superfine grinding applications and creates Back to Basics Hammer Milling and Jet Milling

Cement Grinding Unit Cement Grinding Plant Cement Grinding

Cement grinding unit cost Take the annual output of 600,000 tons of largescale cement grinding station as an example, there are three common options can be recommended: SCHEME 1: roller press + φ 32 ×13m ball mill; SCHEME 2: φ 38 ×13m closed mill; SCHEME 3: clinker fine crusher + cement roller press+φ 32 ×13m ball mill2016年1月1日 Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air (PDF) Analysis of the efficiency of the grinding process in 2018年4月1日 Chemical admixtures, widely used in cement and concrete, have changed the grinding kinetics and hydration kinetics, and improved the microstructural evolution and performance of cement, leading to Energy and cement quality optimization of a cement grinding

vertical roller mill for cement grinding LinkedIn

2023年4月13日 As the demand for highquality cement continues to rise, the need for advanced equipment in cement grinding also increases The vertical roller mill is a mechanical equipment that is widely used 2016年11月7日 The great range of sizes covered by industrial ball mills is well exemplified by Fig 11 and Fig 12 In the first illustration is shown a laboratory batch mill of about 1litre capacity, whilst in Fig 12 is shown a tube mill used in the cement industry the tube having a diameter of about 8 ft and length of about 45 ftGrinding Mills Common Types 911 Metallurgist2021年5月13日 Intelligent Modeling of Cement Plant Mill Unit Using Artificial Neural Networks and Real Data 101109/SIBCON504192021 Conference: 2021 International Siberian Conference on Control and (PDF) Intelligent Modeling of Cement Plant Mill Unit Using

The How, What, and Why of Grinding s flsmidth

The Brazilian cement industry has a long history (more than 70 years) in the production of blended cements, with a nationwide average clinkertocement ratio below 70%₅ In Brazil, the most widely used is currently blast furnace slag from steel mills,₆ though calcined clay and fly ash are also in the mix