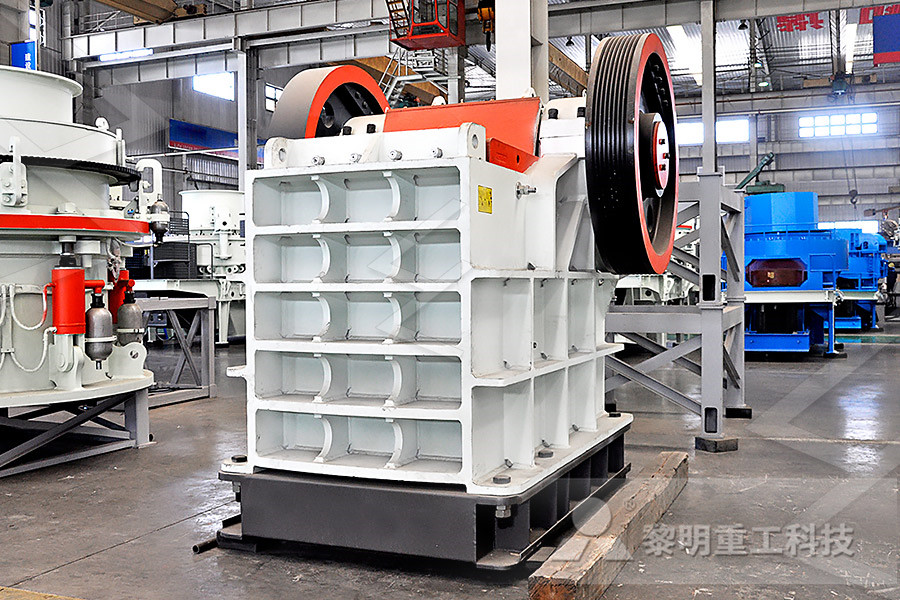

Open Pit Mobile Crushing Plant

2022-07-16T10:07:38+00:00

Fully mobile crushing plant for large openpit mines

2008年1月1日 As part of a priority research and development project launched in 2006, engineers at ThyssenKrupp Fördertechnik developed the concept for a fully mobile crushing plant to enhance mining As part of a priority research and development project launched in 2006, engineers at ThyssenKrupp Fordertechnik developed the concept for a fully mobile crushing plant to Fully mobile crushing plant for large openpit minesSchemes of development of rock using conveyor transport: 1 – excavator; 2 – mobile crushing plant; 3 – downhole conveyor belt; 4 –mobile conveyor reloader; 5 – single Development of technological schemes for openpit

Inpit crushing and conveying technology in openpit

2019年1月18日 As an alternative to the conventional crushingscreening plants, the inpit crushing and conveying system (IPCC) has been widely adopted and utilized worldwide 2021年9月22日 21 The IPCC syste m comprises a combination feeding, crushing, conveying, and discharging systems of whi IPCC systems can be divided in to three (PDF) OVERWIEW OF INPIT CRUSHING CONVEYING TECHNOLOGY IN OPEN PIT 2022年11月9日 The purpose of this paper is to analyse the application of fully mobile plants for raw peat crushing, mixing and separating of wood inclusions and for VWHPLQSHDWPLQLQJ IOPscience

Optimisation of openpit mine production scheduling

Optimisation of openpit mine production scheduling considering optimum transportation system between truck haulage and semimobile inpit crushing and conveying: 2008年11月1日 Abstract The newly developed concept of a fully mobile crawlermounted crushing plant has already proven successful in worldwide surface mining The Fully mobile crawlermounted crushing plant for large open pit 2008年11月15日 The newly developed concept of a fully mobile crawlermounted crushing plant has already proven successful in worldwide surface mining The innovative feature Fully mobile crawlermounted crushing plant for large open pit

Optimum location and relocation plan of semimobile inpit crushing

2022年2月26日 Inpit crushing and conveying (IPCC) systems have attracted more interest among miners as an alternative to the conventional truckshovel transportation system 2015年4月24日 In a conventional openpit mine or quarry, primary crushing is often synonymous with a parade of loud dump trucks driving around, generating dust, noise and consuming excessive amounts of fuel A drill Inpit crushing and conveying saves more than 2008年1月1日 Download Citation Fully mobile crushing plant for large openpit mines As part of a priority research and development project launched in 2006, engineers at ThyssenKrupp Fördertechnik Fully mobile crushing plant for large openpit mines

CHAPTER 105: InPit Crushing ResearchGate

the pit and semimobile and fully mobile plants within the pit The gyratory crusher is the crusher of choice for capacities over 2,500 t/h (metric tons per hour) [2,755 stph, or short tons2020年9月1日 A new conceptual mining method called the nearface stockpile (NFS), which combines the inpit crushing and conveying IPCC system with a precrusher stockpile, has recently been proposed for large open pits with sufficient pit bottom width In the past, stockpiles mainly act as a "buffer" to improve the stability of the production parison of fixed and mobile inpit crushing and 2019年1月18日 As an alternative to the conventional crushingscreening plants, the inpit crushing and conveying system (IPCC) has been widely adopted and utilized worldwide for openpit mining operations [11 Inpit crushing and conveying technology in openpit

A Framework for OpenPit Mine Production Scheduling under SemiMobile

2021年4月13日 Inpit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional truckandshovel systems However, the implementation of the IPCC system can reduce mining flexibility and introduce additional mining sequence requirements This paper investigates the long 2019年6月22日 Equipment selection for openpit mines is a major decision, which in turn, impacts greatly on the economic viability of an operation [2]Models for (mucking), transportation, crushing, etc This also takes into account the services in terms of lighting, ventilation (comports), heat, humidity or any other factor that affects the performance Loading and Haulage Equipment Selection for Optimum In the openpit mining of carbonate rock deposits of uniform strength and diverse strengths with a content of weak differences of up to 30% in complexes with mobile equipment, mobile crushing plants, mobile interstage conveyor reloader and Development of technological schemes for openpit

4typesofcrushingplant Miningpedia

2021年5月25日 With mobile crushing plant, it does not require the support of dump trucks, saving truck operation costs, greatly reducing the procurement costs, transportation and spare parts costs are also fully reduced Mobile crushing plant is a trinity structure, connected by belt machine, mostly used in open pit mine, suitable for largescale mining2021年3月8日 Inpit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional truckandshovel systems However, the implementation of the IPCC system can reduce mining flexibility and introduce additional mining sequence requirements This paper investigates the long A Framework for OpenPit Mine Production Scheduling under SemiMobile 2021年8月2日 The open pit mining load and haul system has been a mainstay of the mining industry for many years While machines have increased in size and scale and automation has become an important Optimising Productivity and Safety of the Open Pit

A comparison of strategic mine planning approaches for inpit crushing

2018年3月1日 FullyMobile InPit Crushing and Conveying (FMIPCC) systems remove the requirement for truck haulage during steady state operation Truck haulage is the most common method for bring material out of an open pit mine and to the process plant, stockpile or waste dump As the mine life matures, the pit becomes deeper and waste 2021年8月2日 The open pit mining load and haul system has been a mainstay of the mining industry for many years While machines have increased in size and scale and automation has become an important Optimising Productivity and Safety of the Open Pit 2023年10月3日 Openpit mining technology Openpit mining clearly offers a number of economic advantages over underground mining, especially now that mineralprocessing technology has advanced to the stage where very lowgrade ores can be treated profitably 100 to 150 years ago, this was not the case, and mining was still much more selectiveOpenPit Mining Method and Process Epiroc

Study on Optimization of Coal Truck Flow in OpenPit Mine

2020年6月23日 A semicontinuous process system consisting of a singlebucket excavator, truck, crushing station, and belt conveyor is the main coal mining process system of a largescale hard coal openpit mine Through analyzing the coal mining production process, the key issues of coal mining truck flow optimization are obtained Statistical method of using 2008年11月15日 @misc{etde, title = {Fully mobile crawlermounted crushing plant for large open pit mines; Vollmobile Brechanlage auf Raupen fuer Grosstagebaue} author = {Mentges, Ulrich} abstractNote = {The newly developed concept of a fully mobile crawlermounted crushing plant has already proven successful in worldwide surface Fully mobile crawlermounted crushing plant for large open pit 2021年2月12日 Inpit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of openpit mining operations and what is likely to happen in the future The use of trucks and shovels for loading and hauling has been used as a dominant system in openpit and opencast mines due to their large Determination of semimobile inpit crushing and conveying

Energy saving ideas for open pit mining OSTIGOV

The use of semimobile crushing plants in open pit mines makes a combination of trucks and conveyors economical and energy efficient The increasing cost of Diesel fuel is making truck haulage in open pit mines less economic Belt conveyor systems have much lower operating costs but are not as flexible in their application and require more 2019年4月10日 Fullymobile inpit crushing stations are best applied in greenfield operations Crusher selection depends on various parameters : Material properties (moisture content, density, abrasiveness) Application requirements (product size, feed size, capacity) Fig 2 shows division of inpit crushers related to maximum output and Evaluation and Risk Analysis of OpenPit Mining Operations2018年1月1日 InPit Crushing and Conveying (IPCC) has gained momentum in recent years to replace trucks partially or fully in large open pit mines because of the shoveltruck system's increasing fuel and OpenPit Mine Production Planning and Scheduling: A Research