Formula Calculate Profile Crusher Cost

2019-12-24T00:12:40+00:00

Cost Analysis for Crushing and Screening Part II CORE

2021年8月13日 model earlier developed by Heyman and Lindström in order to calculate the cost per metric ton within the world of crushing and screening Equation 4: Production cost during up jaw or a gyratory crusher and screening equipment The secondary The purpose of this paper is to introduce a new production cost‐model within the world of comminution There are many ways to determine different production costs in the Cost Analysis for Crushing and Screening – Part I2016年2月24日 The largest primary gyratory crushers cost US $2 million or more, while overall crushing plant costs can be as high as $18 million It’s necessary therefore to Crushing Plant Design and Layout Considerations 911

Table 6 Energy consumption values of each

consumption values of the crushers were calculated with obtained ampere values by using first equation given above for each blast test and energy consumption values of the crushers per tonne2016年1月10日 The Experts: SandVik Mining + and Quarry Academy = all agree The approximate running costs for crushing plants Crusher Operating Costs: How to Optimize and Fig 1 Scheme of a rotarycone crusher: a – sectional view of the crusher; b – section AA The power spent on material crushing is consumed to overcome the moment of force M: Drive power calculation of a crushing machine working

Crusher Efficiency Calculations 911 Metallurgist

2014年9月15日 Crusher Efficiency Calculations Crusher Efficiency Calculations The following example demonstrates a method of selecting the components of an aggregate 2015年7月14日 Impact Crushers Design And Calculations Impact crusher in the production process, the main parameters of the equipment has an important significance Impact Crushers Design And Calculations Pages2023年1月10日 To calculate the cost per ton of crushing stone, you will need to determine the following: The size of the stone: Larger stone will typically cost more to crush than How to calculate the cost per ton of crushing and screening

Jaw Crusher ScienceDirect

2016年1月1日 Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW Crushers of this size are 2022年2月25日 Multiply the length (L), in feet, by the width (W), in feet, by the height (H), in feet, and divide by 27 This number is how many cubic yards of crushed stone you need As an example, let's say your DIY How Much Crushed Stone Do You Need? A Sure 2021年2月17日 31 Introduction The unit cost of logging or road construction is essentially derived by dividing cost by production In its simplest case, if you rented a tractor with operator for $60 per hour including all fuel and other costs and you excavated 100 cubic meters per hour, your unit cost for excavation would be $060 per cubic meter3 CALCULATION OF MACHINE RATES Food and

Capacity Calculations of the Crasher with Stops on a Roll

2022年8月21日 The design has been developed for a singleroll crusher with the forced supply of destroyed material into the crushing zone []The capture of a crushed piece occurs due to the stop located on the roll (see Fig 1); in this case, the condition for formation of a complex stress state in the crushed piece is observed, and the energy consumption is 2023年1月5日 You can also determine the capacity of the crusher by using the following formula: capacity = ( throughput / ( closedsidesetting x workindex ) ) x constant Another way to determine the How to determine the capacity of impact crusher? LinkedIn2022年9月10日 Generally, the scale of operations involves the purchase of a single mining equipment that may cost several millions of dollars, but as productivity increases over time, the cost of operation outweighs the purchasing cost of the equipment The equipment selection problem is often affected with a cascade of interdependent variables and Full article: Optimization of the fleet per shovel productivity

Crusher an overview ScienceDirect Topics

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The One of the most famous empirical formulas is based on the fact that the performance of a singletoggle jaw crusher is directly proportional to the area of the charging opening described by F Taggart in 1927 [16]: Q =930 , ⋅L⋅B where L and B are the length and the width of the jaw crusher charging opening, mRIVLQJOH WRJJOHMDZ FUXVKHU 2019年5月13日 Additionally, jaw crusher feed should be prescreened using a grizzly screen prior to crushing to remove material finer than the closedside setting Setting jaw crushers Ideally, the reduction ratio of a jaw crusher should be 6to1 There are different ways to calculate reduction ratio, but the best way is something called the P80 factorTips to maximize crushing efficiency Pit Quarry

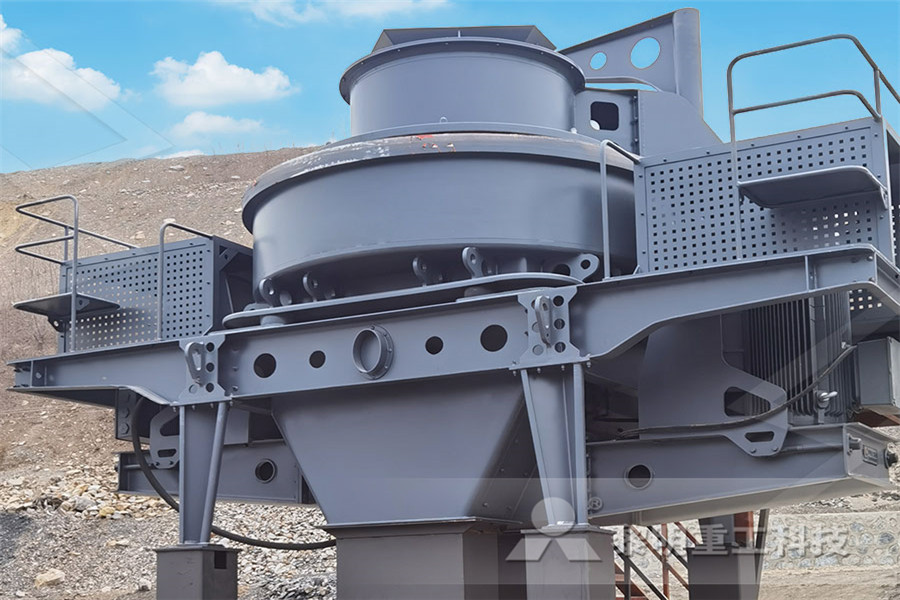

Selecting the right crusher for your operations Quarry

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or less Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but These design parameters were varied to analyse deformation and stress distribution during crushing Design of experiment techniques was used to determine the optimal design parameters Power draw of the crusher when varying the 2015年12月16日 Rules of Thumb in Engineering Practice Donald RWoods Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusherRock Crushing Rule of Thumb 911 Metallurgist

how to calculate the production capacity of cone crusher

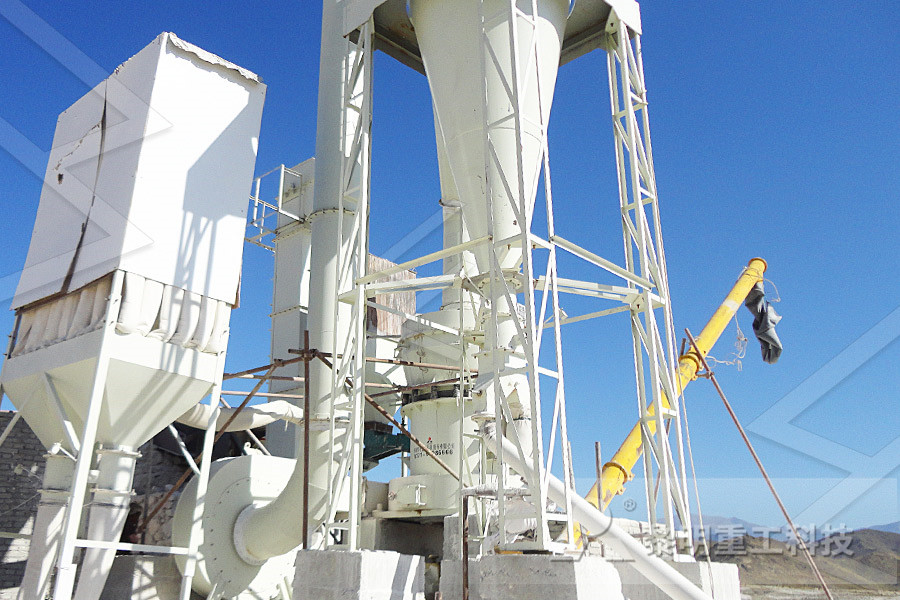

2023年1月28日 Once you have this information, you can use the following formula to calculate the production capacity of the crusher: Capacity = (60 x Speed x Throw x CSS) / (2 x π x Bulk Density) Keep in mind 2016年1月1日 Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW Crushers of this size are manufactured by Locomo, () and others The crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors Table 41Jaw Crusher ScienceDirect2021年6月24日 Whether you need a single crusher, a multistage process or a complete plant, we assist you with the right design for the most costeff ective crushing process We are the world’s leading supplier of both unit machines and complete aggregates processing systems Comprehensive process solutions Your system may involve a whole series of Crushing and Screening Handbook AusIMM

Rolls Crushers Smooth Roll Crushers, Wroking, Construction

2022年11月13日 A smooth Roll crusher consists of two heavy metal rolls of the same diameter placed side by side each other in the horizontal position The rolls are rotated towards each other at the speed One of the shafts moves in fixed bearings while others move in movable bearings The clearance between the rolls can be adjusted accordingly \n \n Conveyor Calc Freight Metrics \n Calculate the belt power for a belt conveyor with this calculator to assist Engineers and DesignersSorry there is a problem with the databaseWe're in theConveyor Belt Calculating ChartThe chart is a graphical representation of the formula : Where,p = kgW(L + 10H) p = the correct number of plies k formula to calculate counterweight in conveyors2014年9月1日 The final form of Bond's equation can be written as [4]: (2) E = 10 C W i 1 P 80 − 1 F 80 kWh ton where C = a tabulated constant depending on type and condition (wet or dry) of comminution equipment, F 80 = 80% passing sieve size of the feed, μm, P 80 = 80% passing sieve size of the product, μm, W i = Bond work index: the work required to Assessing the energy efficiency of a jaw crusher ScienceDirect

A review of modeling and control strategies for cone crushers

2021年8月15日 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017)The maximum distance between the mantle and concave, on the other 2020年5月7日 Now you have fully accounted for the ALL the cost of materials purchased/used up in 1m3 of concrete R400 (sand) + R43077 (cement) = R83077 per m3 of mortar R504 + 45231 = R95631 per m3 of Cost Estimating 101 Part 3 Bulking, wastage, and cut loss